Auricularia polytricha cultivation matrix and preparation method thereof

A cultivation substrate and Auricularia auricularia technology, which is applied in the field of edible fungus cultivation, can solve problems such as soaring prices, high production costs of Auricularia auriculae, unfavorable steady and sustainable development of the edible fungus industry, etc., and achieve the effect of shortening the cycle and shortening the cycle of fruiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

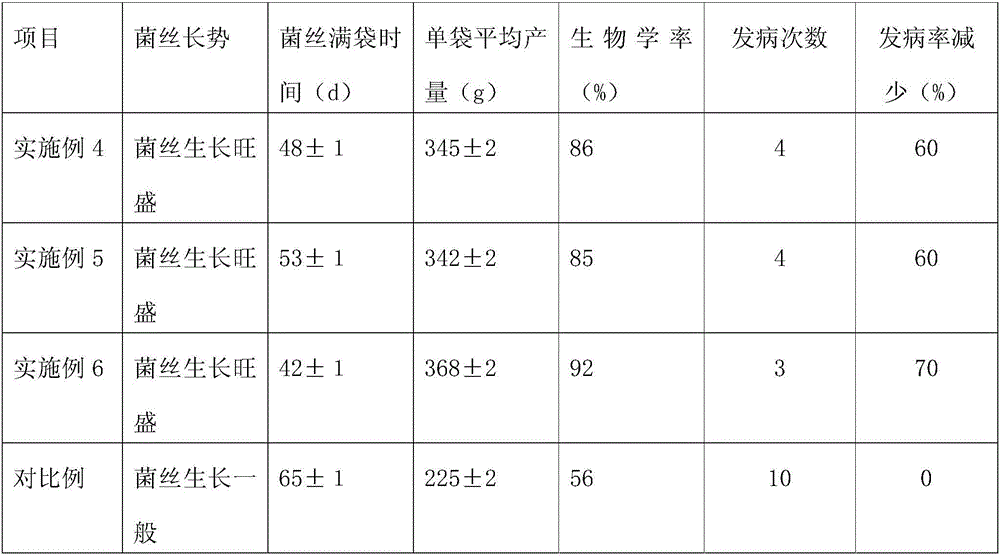

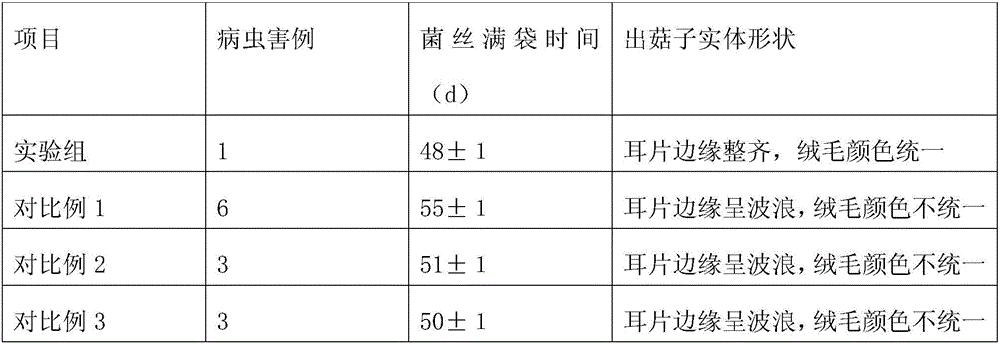

Examples

Embodiment 1

[0032] A fungus cultivation substrate, according to weight parts, including 22 parts of first-grade broken shavings whose length, thickness and width are 70×1.0×50 mm, and 4×0.12×0.2 mm in length, thickness and width 3 parts of secondary crushed wood shavings, 15 parts of Trichoderma antibacterial agent, 10 parts of soy sauce waste residue with a salt content less than 1% after the leftovers of soy sauce production have been washed and salted, 10 parts of soybean powder, 10 parts of carrageenan filter residue, water chestnut shell 10 parts, 10 parts of distiller's grain waste residue, 10 parts of banana peel, 8 parts of coconut fiber, 8 parts of chaff, 6 parts of light calcium carbonate, 5 parts of water hyacinth dregs, 3 parts of rapeseed straw and 2 parts of sugarcane molasses;

[0033] Among them, the Trichoderma antibacterial agent is prepared by cultivating Trichoderma konningen on an inclined plane so that its spore concentration is 2×10 7 4mg / mL of limonin was added to ...

Embodiment 2

[0036] A kind of Auricularia auricula cultivation substrate, according to parts by weight, including 16 parts of first-grade broken shavings whose length, thickness and width are 60×0.4×20mm, and 3×0.1×0.15mm in length, thickness and width 4 parts of secondary crushed shavings, 10 parts of trichoderma antibacterial agent, 8 parts of soy sauce waste residue with a salt content of less than 1% after the leftovers of soy sauce production have been washed and salted, 8 parts of soybean powder, 8 parts of carrageenan filter residue, water chestnut shell 8 parts, 8 parts of distiller's grain waste residue, 5 parts of banana peel, 3 parts of coconut fiber, 3 parts of chaff, 2 parts of light calcium carbonate, 1 part of water hyacinth dregs, 1 part of rapeseed straw and 1 part of sugarcane molasses;

[0037] Among them, the Trichoderma antibacterial agent is prepared by cultivating Trichoderma konningen on an inclined plane so that its spore concentration is 2×10 7 The seed liquor of ...

Embodiment 3

[0040] A fungus cultivation substrate, according to weight parts, including 26 parts of first-grade broken shavings whose length, thickness and width are 90×1.2×90mm, and 8×0.15×0.25mm in length, thickness and width 4 parts of secondary crushed shavings, 20 parts of trichoderma antibacterial agent, 20 parts of soy sauce waste residue with a salt content less than 1% after washing and salting the leftovers from the production of soy sauce, 15 parts of soybean powder, 15 parts of carrageenan filter residue, water chestnut shell 15 parts, 15 parts of distiller's grain waste residue, 15 parts of banana peel, 12 parts of coconut fiber, 10 parts of chaff, 10 parts of light calcium carbonate, 10 parts of water hyacinth dregs, 5 parts of rapeseed straw and 5 parts of sugarcane molasses;

[0041] Among them, the Trichoderma antibacterial agent is prepared by cultivating Trichoderma konningen on an inclined plane so that its spore concentration is 2×10 7 The seed liquid of 1 spore / mL th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com