Method of preparing nanometer hafnium oxide particles of different crystal forms by adjusting alkali concentration

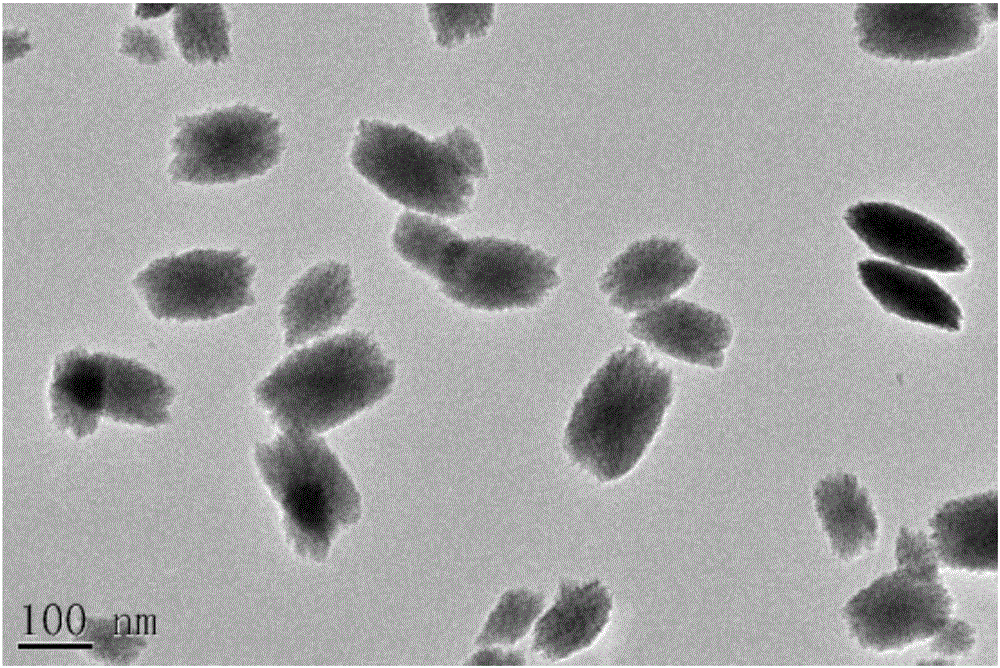

A technology of hafnium dioxide and hafnium oxychloride is applied in the field of preparation of nanometer hafnium dioxide materials, can solve the problems of poor powder dispersibility, expensive raw materials, high agglomeration, etc., and achieves good application prospects, good dispersibility, and particle size. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

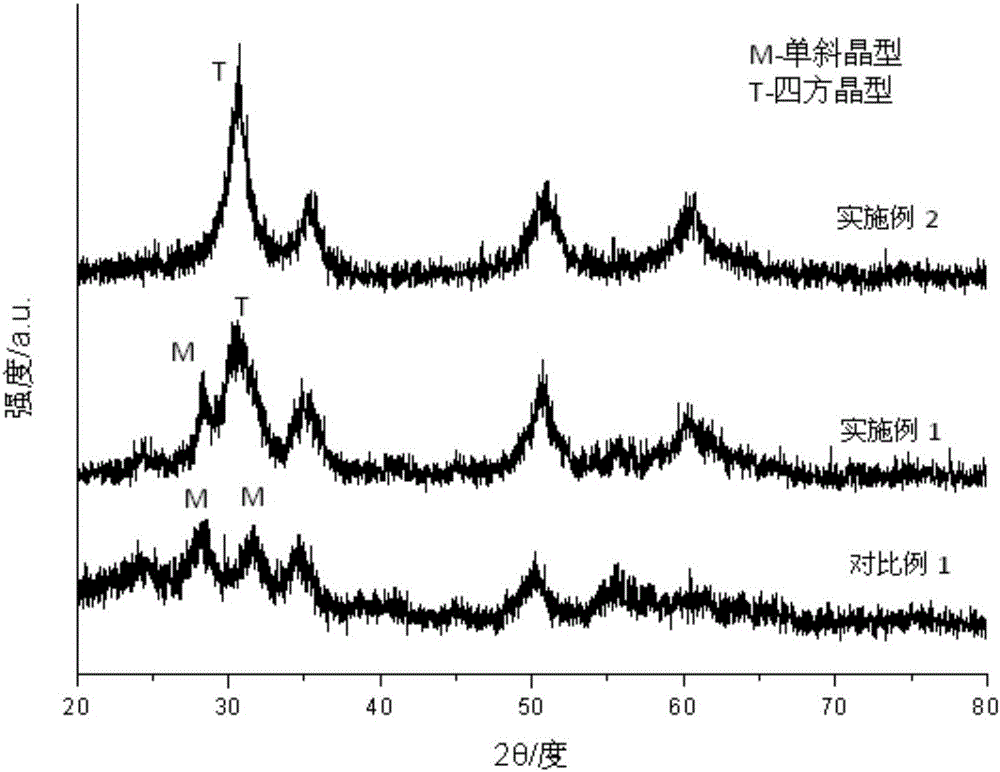

Embodiment 1

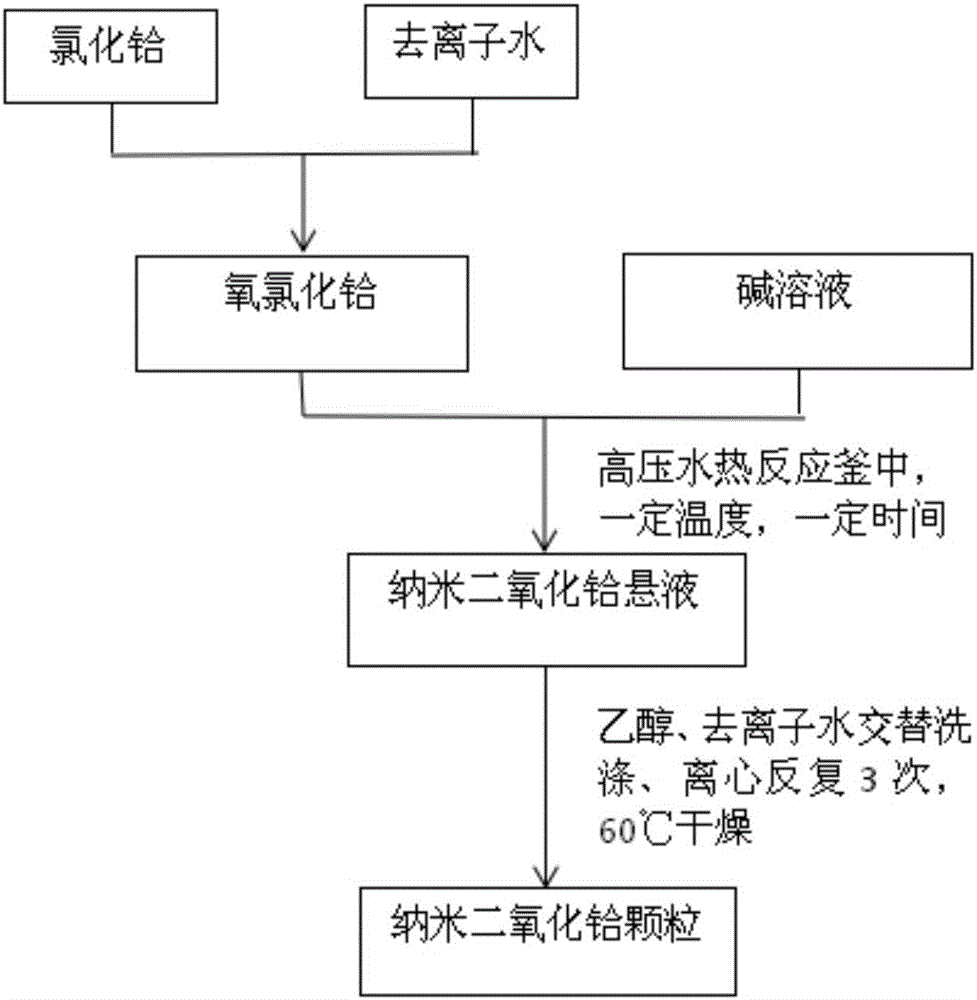

[0029] (1) Weigh 0.16g of hafnium tetrachloride powder and dissolve it in 10mL of deionized water to form a hafnium oxychloride solution;

[0030] (2) Weigh 2.4g of sodium hydroxide and dissolve it in 10mL of deionized water, then drop the alkali solution into the hafnium oxychloride solution to obtain a mixed solution;

[0031] (3) Transfer the obtained mixed solution to a high-pressure hydrothermal reactor with a polytetrafluoroethylene liner of 100 mL, then tighten the reactor, place it in a blast drying oven, and react at 120° C. for 24 hours.

[0032] (4) After the reaction is over, after the high-pressure hydrothermal reactor is naturally cooled to room temperature, wash with absolute ethanol, centrifuge at 10,000rpm for 15min to remove the supernatant, then wash with deionized water, and centrifuge at 10,000rpm Centrifuge for 15 minutes to remove the supernatant, repeat this cycle 3 times, finally wash with absolute ethanol, centrifuge at 10,000 rpm for 15 minutes to ob...

Embodiment 2

[0035] (1) Weigh 0.16g of hafnium tetrachloride powder and dissolve it in 10mL of deionized water to form a hafnium oxychloride solution;

[0036] (2) Weigh 4.0 g of sodium hydroxide and dissolve it in 10 mL of deionized water, then drop the alkali solution into the hafnium oxychloride solution to obtain a mixed solution;

[0037] (3) Transfer the obtained mixed solution to a high-pressure hydrothermal reactor with a polytetrafluoroethylene liner of 100 mL, then tighten the reactor, place it in a blast drying oven, and react at 120° C. for 24 hours.

[0038] (4) After the reaction is over, after the high-pressure hydrothermal reactor is naturally cooled to room temperature, wash with absolute ethanol, centrifuge at 10,000rpm for 15min to remove the supernatant, then wash with deionized water, and centrifuge at 10,000rpm Centrifuge for 15 minutes to remove the supernatant, repeat this cycle 3 times, finally wash with absolute ethanol, centrifuge at 10,000 rpm for 15 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com