A method for preparing phase-change microcapsules by hydrothermal method

A technology of phase change microcapsules and hydrothermal method, which is applied in heat exchange materials, chemical instruments and methods, bulk chemical production, etc., to achieve the effects of controllable product shape, simple reaction, and adjustable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

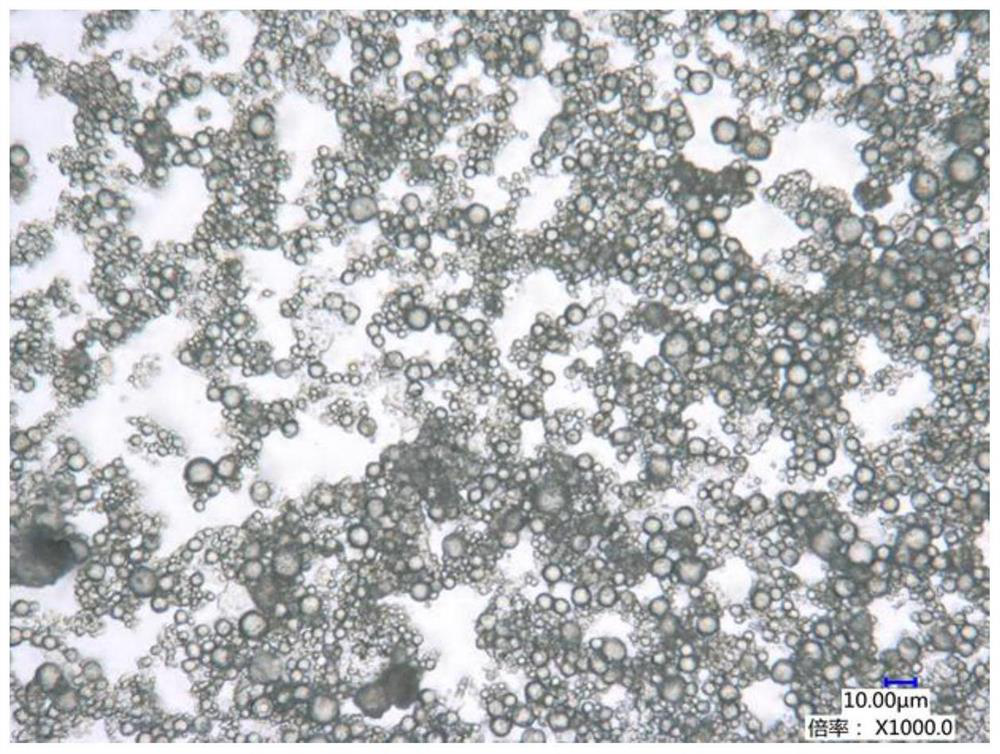

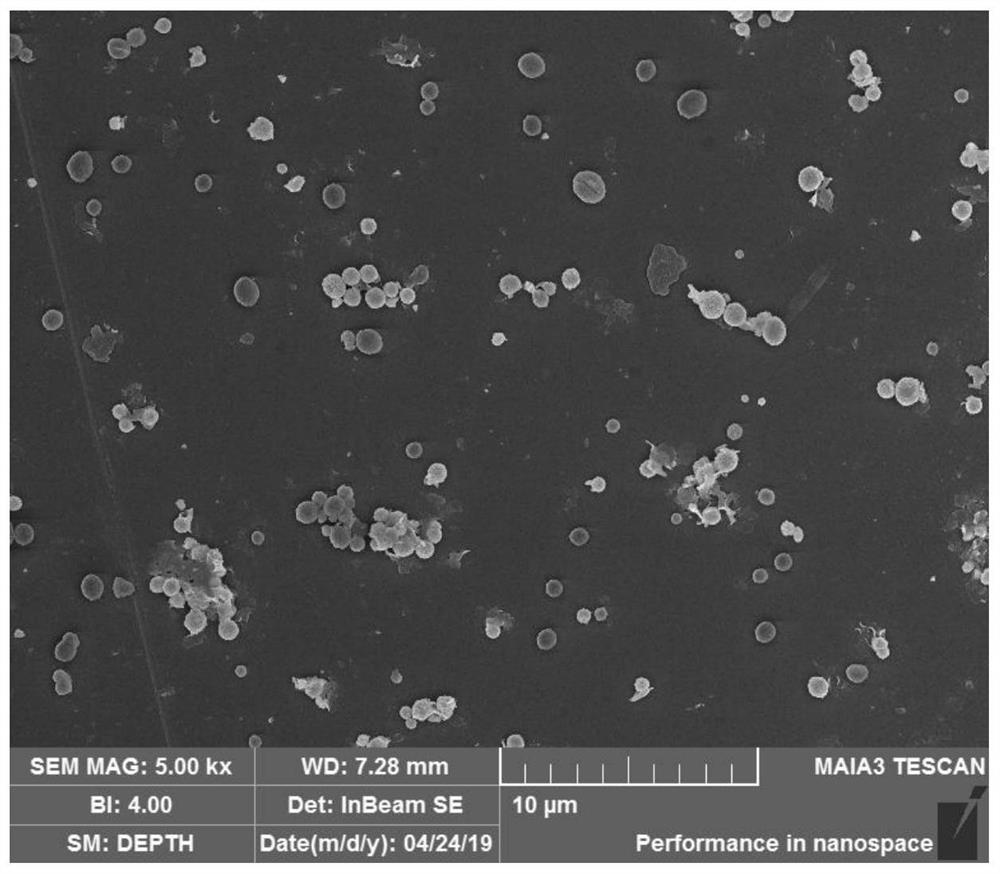

Image

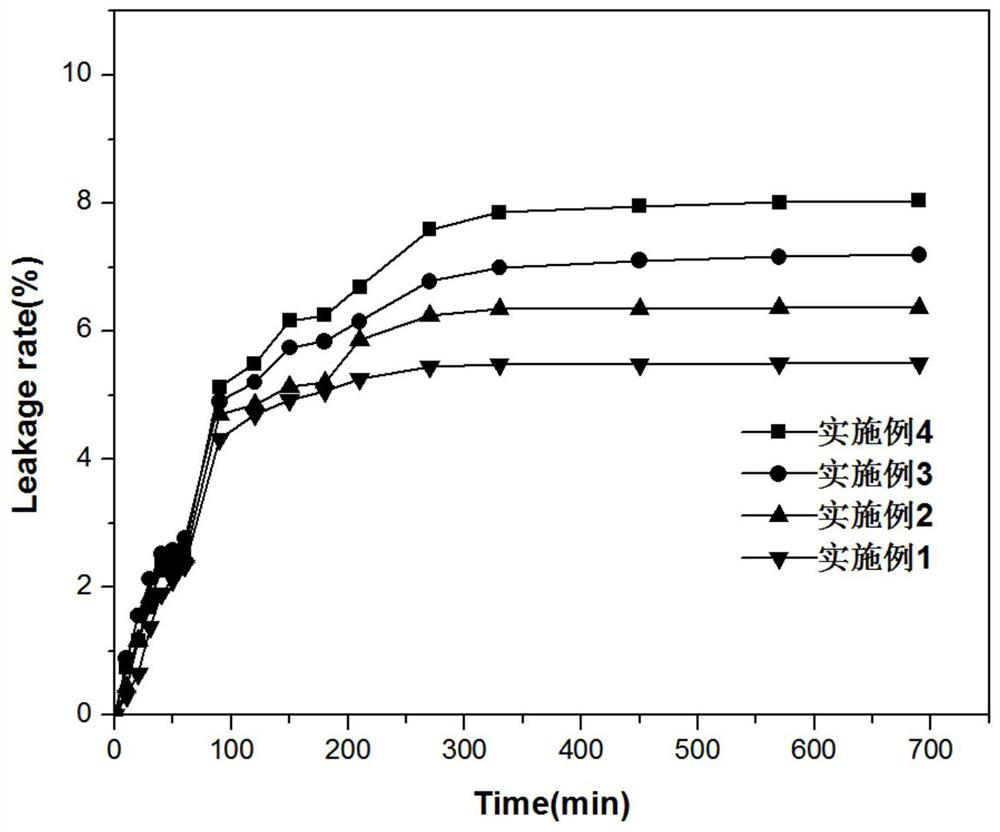

Examples

Embodiment 1

[0030] A method for preparing phase-change microcapsules by hydrothermal method, comprising the following steps:

[0031] Step 1. Dissolve 8g of paraffin wax and 25mL of anionic surfactant styrene-maleic anhydride copolymer with a concentration of 2wt% and 50mL of deionized water into a mixed liquid in a constant temperature water bath at 80°C; emulsify with a high-shear emulsifier, The rotation speed is 19000r / min, and the emulsification time is 5min to obtain phase change material emulsion;

[0032] Step 2, 3.341g bismuth nitrate was dissolved in 80mL concentration of 2.5% nitric acid solution to make bismuth nitrate solution; 1.136487g sodium tungstate was dissolved in 80mL deionized water to make sodium tungstate solution; bismuth nitrate solution was dissolved in 0.02 Drop into the phase-change material emulsion at 80°C at a rate of mL / s, and stir for 3 hours at a speed of 600r / min; then drop the sodium tungstate solution into the phase-change material emulsion at a rate ...

Embodiment 2

[0037] A method for preparing phase-change microcapsules by hydrothermal method, comprising the following steps:

[0038] Step 1. Dissolve 8g of paraffin wax and 25mL of anionic surfactant styrene-maleic anhydride copolymer with a concentration of 2wt% and 50mL of deionized water into a mixed liquid in a constant temperature water bath at 80°C; emulsify with a high-shear emulsifier, The rotation speed is 19000r / min, and the emulsification time is 5min to obtain phase change material emulsion;

[0039]Step 2, 6.667g bismuth nitrate is dissolved in the nitric acid solution that 80mL concentration is 2.5% and makes bismuth nitrate solution; 2.632g borax is dissolved in 80mL deionized water and makes borax solution; Drop into the phase change material emulsion at 80°C and stir for 3h at a speed of 600r / min; then drop the borax solution into the phase change material emulsion at a speed of 0.005mL / s and stir for 1h at a speed of 300r / min. During the stirring process, ammonia water...

Embodiment 3

[0044] A method for preparing phase-change microcapsules by hydrothermal method, comprising the following steps:

[0045] Step 1. Dissolve 8g of paraffin wax and 25mL of anionic surfactant styrene-maleic anhydride copolymer with a concentration of 2wt% and 50mL of deionized water into a mixed liquid in a constant temperature water bath at 80°C; emulsify with a high-shear emulsifier, The rotation speed is 19000r / min, and the emulsification time is 5min to obtain phase change material emulsion;

[0046] Step 2, 3.341g bismuth nitrate was dissolved in 80mL concentration of 2.5% nitric acid solution to make bismuth nitrate solution; 1.136487g sodium tungstate was dissolved in 80mL deionized water to make sodium tungstate solution; bismuth nitrate solution was dissolved in 0.02 Drop into the phase-change material emulsion at 80°C at a rate of mL / s, and stir for 3 hours at a speed of 600r / min; then drop the sodium tungstate solution into the phase-change material emulsion at a rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com