A solder used for fusion welding of nickel-based superalloys resistant to molten salt corrosion

A nickel-based superalloy and molten salt corrosion technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of increased sensitivity of weld cracks, achieve enhanced tellurium embrittlement ability, weld Beautiful shape, improve the effect of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

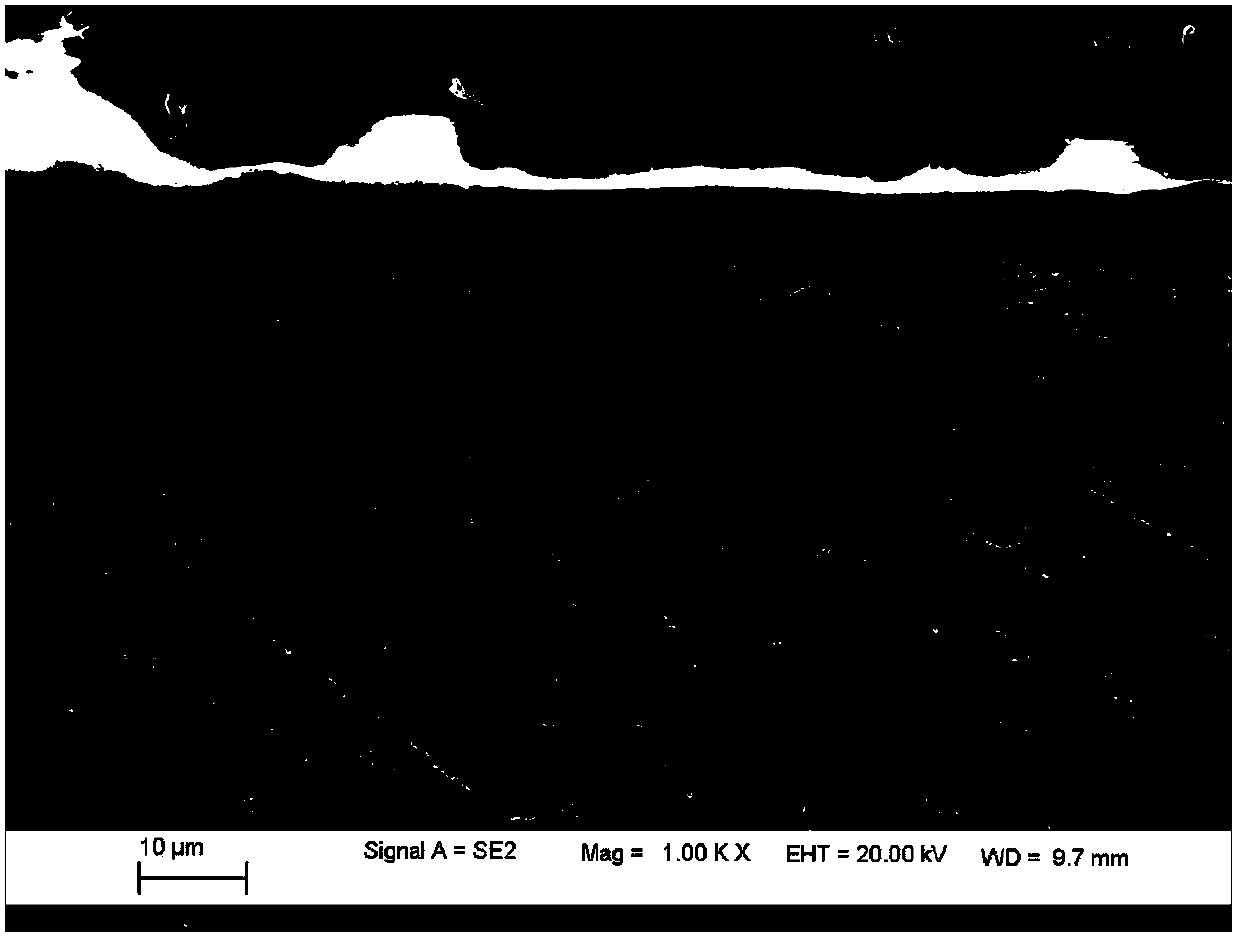

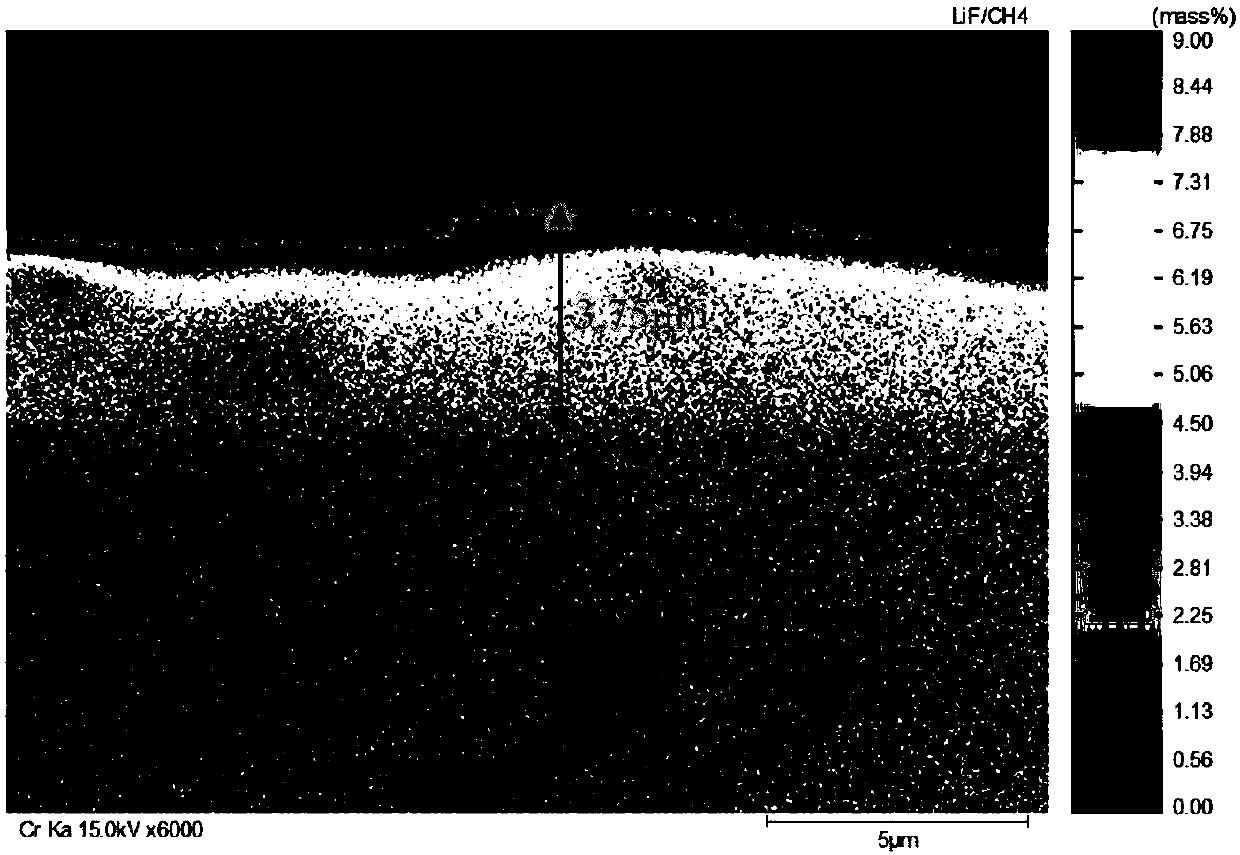

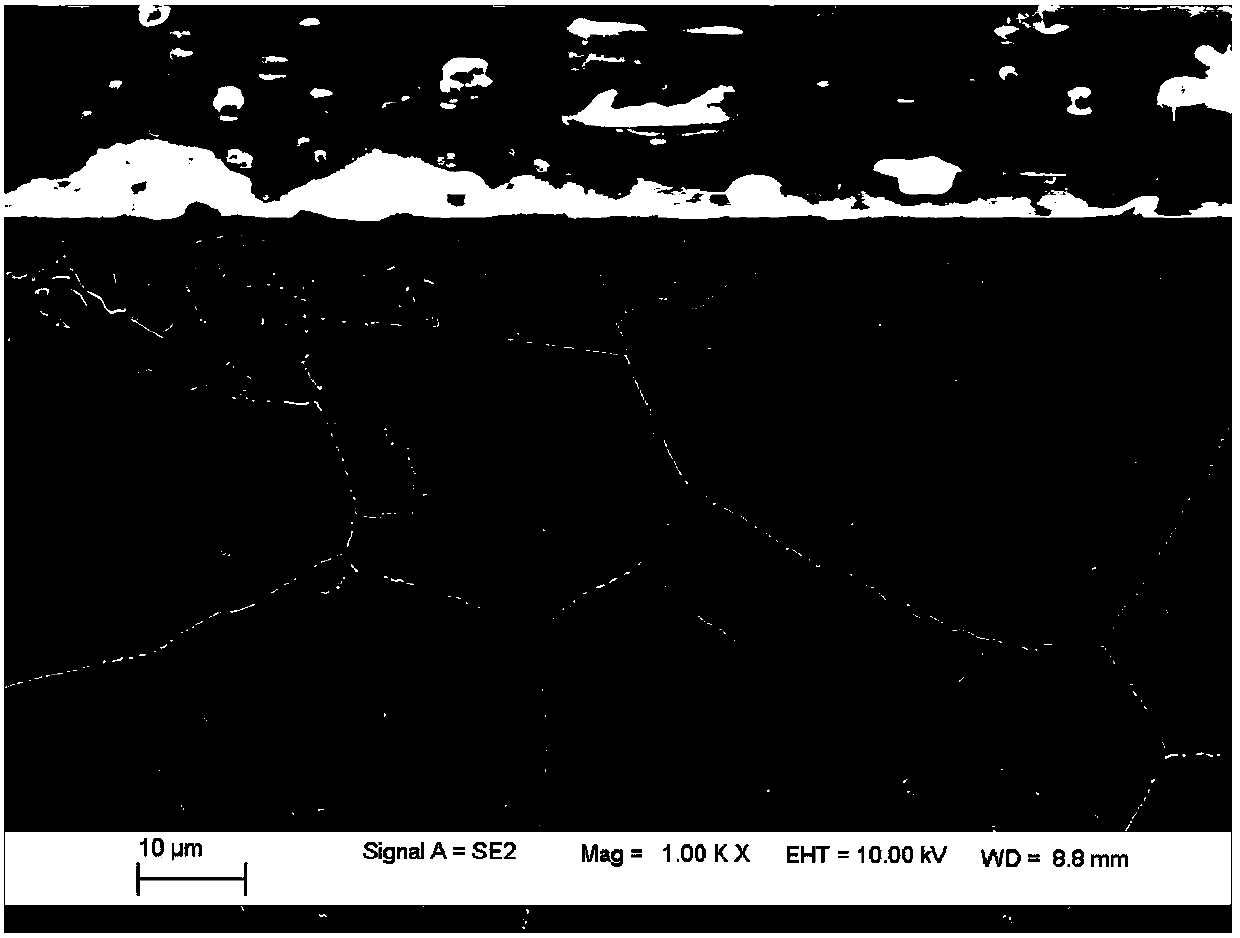

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0027] In order to meet the safety and reliability of welded structural parts for molten salt stacking, the present invention proposes a solder for molten salt corrosion-resistant nickel-based superalloy fusion welding, and its components (percentage by weight) are specifically as follows:

[0028] The content of C is controlled between 0.03% and 0.06%, preferably between 0.05% and 0.06%, and C within this range makes the weld seam have better strength and toughness matching. The higher the C content, the strength of the weld will increase, but the plasticity will decrease accordingly. In addition, if the C content is too large, a large number of carbides will be formed in the weld, which will reduce the stability of the weld structure. If the carbon content is too low, It will reduce the strength of the weld.

[0029] The content of Mn is controlled b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com