Gold-cladded copper selenide nano-particles as well as preparation method and application thereof

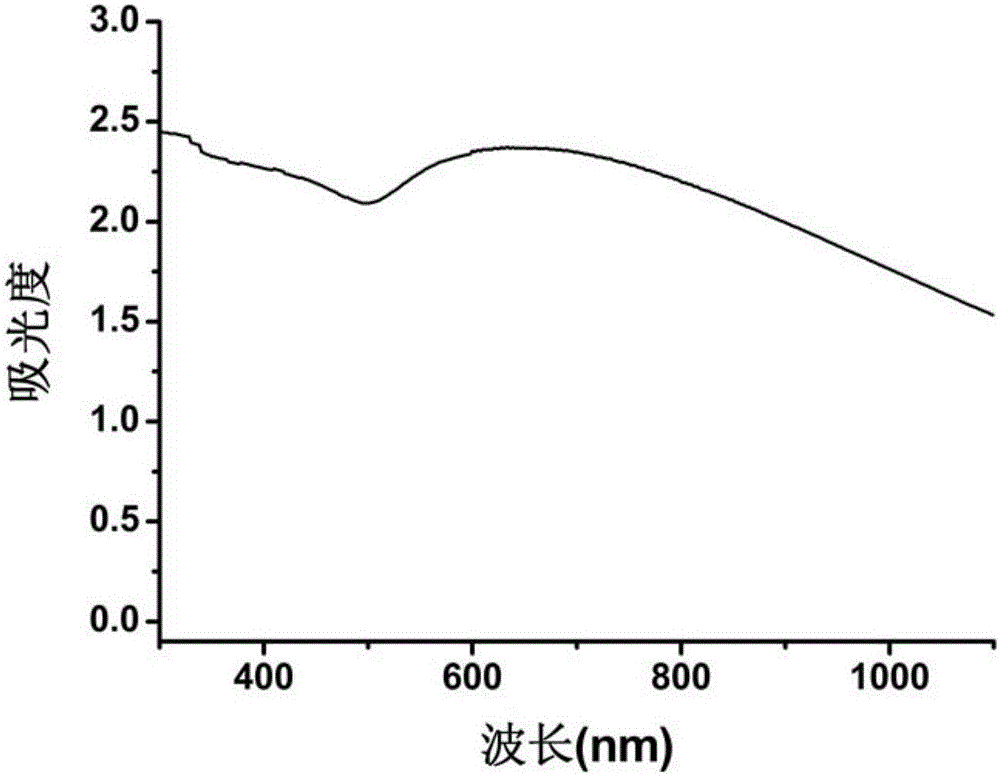

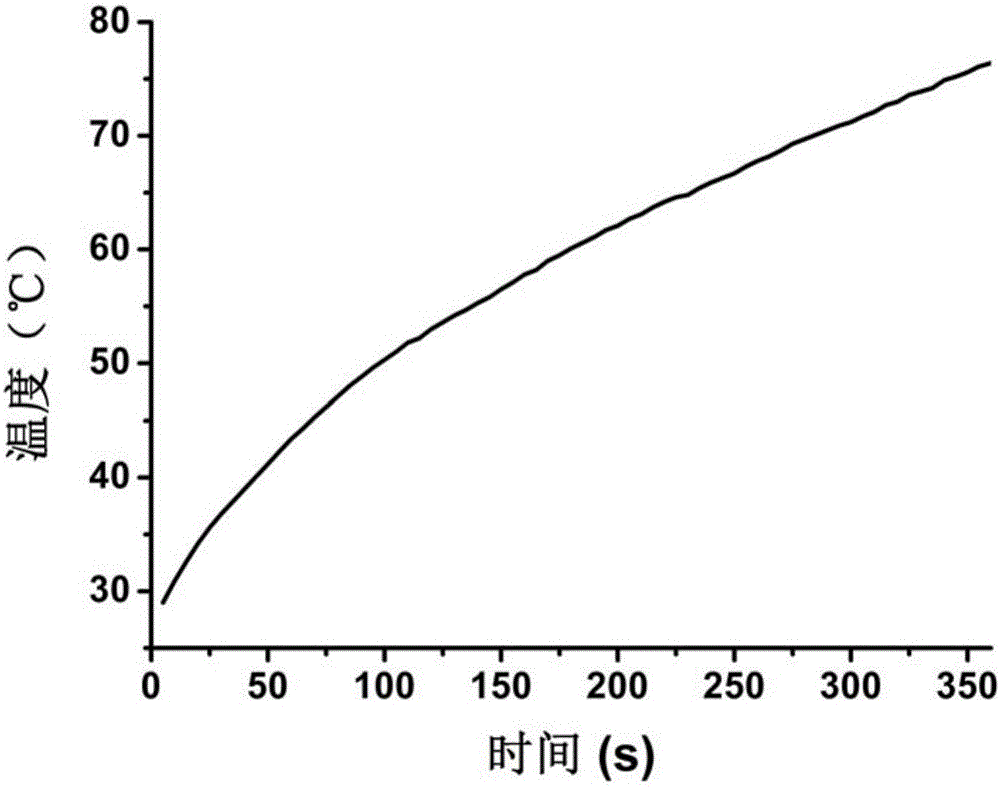

A nanoparticle, copper selenide technology, applied in metal processing equipment, wave energy or particle radiation treatment materials, pharmaceutical formulations, etc. Effects of high intensity, photothermal conversion efficiency, and low cytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

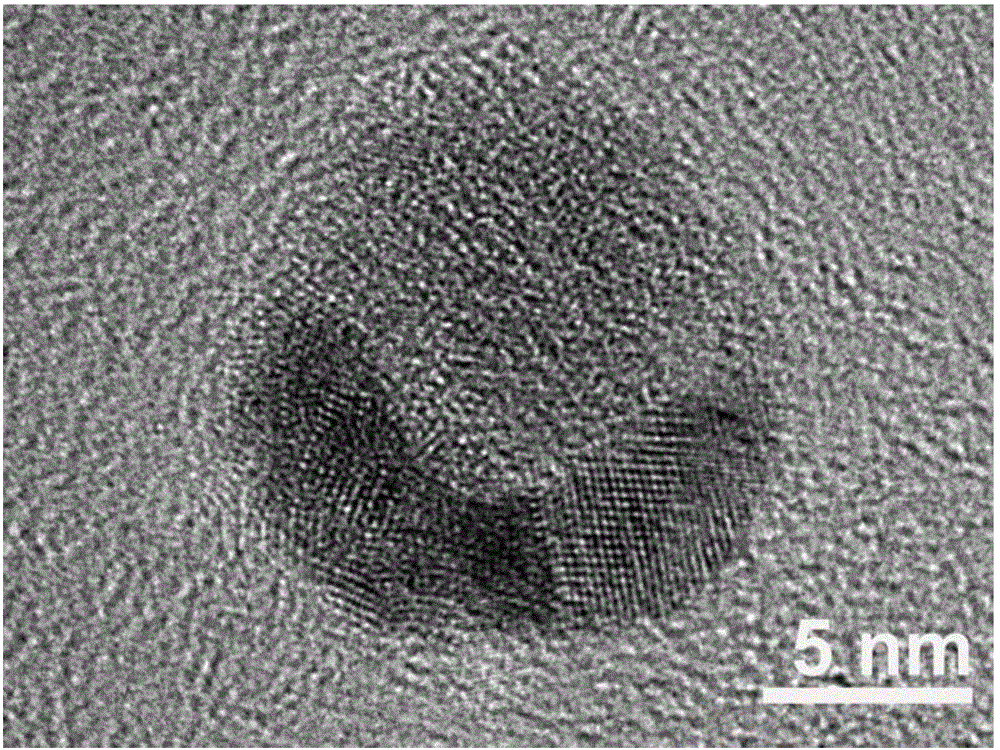

[0037] (1) Add anhydrous CuCl (0.099g, 1mmol) into a reaction flask containing 5mL oleylamine and 5mL 1-octadecene mixed solvent, blow nitrogen, heat to 80°C for 1h to remove oxygen and moisture in the system, Stir and heat to 300°C. In another reaction flask, nitrogen gas was passed, and the mixture of 0.039g selenium powder (0.5mmol) and 3mL oleylamine was heated to 150°C for 1h, then heated to 230°C for 1h to completely dissolve the selenium powder, and then the solution was cooled to 100°C Afterwards, it was quickly injected into the reaction bottle containing CuCl, and kept at 300° C. for 15 minutes to react. Rapidly cooled to room temperature, added 5 mL of toluene to the reaction system, added ethanol and washed twice by centrifugation, and finally obtained Cu 2-x Se nanocrystals were dispersed in 10 mL of chloroform.

[0038] (2) 2.5mmol chloroauric acid (HAuCl 4 ·3H 2 O) Dissolved in 10 mL of chloroform and 1 mmol of oleylamine, an additional 10 mL containing 40 m...

Embodiment 2

[0043] (1) Add anhydrous CuCl (0.099g, 1mmol) into a reaction flask containing 5mL oleylamine and 5mL 1-octadecene mixed solvent, blow nitrogen, heat to 80°C for 1h to remove oxygen and moisture in the system, Stir and heat to 280°C. In another reaction flask, nitrogen gas was passed, and the mixture of 0.039g selenium powder (0.5mmol) and 3mL oleylamine was heated to 150°C for 1h, then heated to 230°C for 1h to completely dissolve the selenium powder, and then the solution was cooled to 100°C Afterwards, it was quickly injected into the reaction bottle containing CuCl, and kept at 280° C. for 15 minutes. Rapidly cooled to room temperature, added 5 mL of toluene to the reaction system, added ethanol and washed twice by centrifugation, and finally obtained Cu 2-x Se nanocrystals were dispersed in 10 mL of chloroform.

[0044] (2) 2.5mmol chloroauric acid (HAuCl 4 ·3H 2 O) Dissolve in 8 mL of chloroform and 1 mmol of oleylamine and prepare additionally 12 mL containing 40 mg...

Embodiment 3

[0048] The preparation method of gold-coated copper selenide nanoparticles in this embodiment specifically includes the following steps:

[0049] (1) Add the monovalent copper salt to the organic solvent containing oleylamine and alkene, pass in an inert gas to remove oxygen and water, then stir and heat to 250°C to prepare a mixed reaction solution;

[0050] (2) Mix the selenium powder with oleylamine, pass in an inert gas, heat to 150°C to completely dissolve the selenium powder, then cool to 100°C, inject it into the mixed reaction solution of step (1) quickly, and keep the temperature at 250°C ℃, reacted for 30min, then rapidly cooled to room temperature, and then centrifuged and washed to obtain Cu 2-X Se nanocrystals;

[0051] (3) Cu obtained by step (2) 2-X Se nanocrystals were placed in chloroform containing oleylamine and formulated as Cu 2-X Se nanocrystal solution;

[0052] (4) prepare the chloroform solution of soluble gold salt, and slowly add the chloroform s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com