Swine fever poison-clearing feed additive, preparation method and application thereof

A feed additive, swine fever virus technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of public health and food safety damage, the cure rate is not ideal, chemical drug residues and other problems, to improve the utilization rate of feed, Significant curative effect, quick-acting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

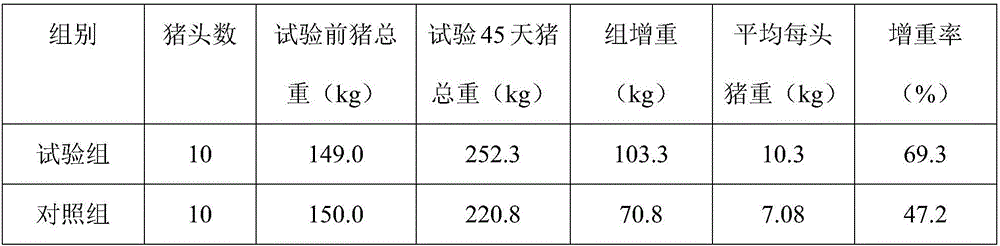

Examples

Embodiment 1

[0024] In the embodiment of the present invention, the swine fever Duqing feed additive is composed of the following raw materials in parts by weight: 20 parts of Ailei, 1 part of Mianzao, 26 parts of Sagittarius leaves, 15 parts of camphor root, and 10 parts of nutmeg.

[0025] Grind Elephant, Arthia sativa, and camphor root, pass through a 100-mesh sieve, add 15 times the mass of the three in an ethanol solution with a volume concentration of 60%, heat and stir at 77°C for 0.8h, and then heat and stir at 90°C Treated for 1.8h, filtered to obtain the filtrate. Grind the jujube and nutmeg, pass through a 200-mesh sieve, add calcium hydrogen phosphate acetic acid solution with 5 times the mass of the two, the mass content of calcium hydrogen phosphate in the calcium hydrogen phosphate acetic acid solution is 5%, soak at 65°C for 3.5h, Stir at 110° C. for 50 minutes, and then stir at 125° C. for 10 minutes to obtain a mixed material. The filtrate is mixed with the mixed materia...

Embodiment 2

[0027] In the embodiment of the present invention, the swine fever Duqing feed additive is composed of the following raw materials in parts by weight: 28 parts of Ailei, 8 parts of Mianzao, 34 parts of Sagittarius leaves, 23 parts of camphor root, and 18 parts of nutmeg.

[0028] Pulverize Elephantia chinensis, arrowroot leaves, and camphor root, pass through a 100-mesh sieve, add 60% ethanol solution 15 times the mass of the three, heat and stir at 80°C for 1 hour, then heat and stir at 92°C for 2 hours, and filter to obtain filtrate. Crush the jujube and nutmeg, pass through a 200-mesh sieve, add calcium hydrogen phosphate acetic acid solution of 6 times the mass of the two, the mass content of calcium hydrogen phosphate in the calcium hydrogen phosphate acetic acid solution is 8%, soak at 68 ° C for 4 hours, and then Stir at 115° C. for 60 min, then stir at 130° C. for 15 min to obtain a mixed material. The filtrate is mixed with the mixed material, stirred and dried at a ...

Embodiment 3

[0030] In the embodiment of the present invention, the swine fever Duqing feed additive is composed of the following raw materials in parts by weight: 22 parts of Ailei, 3 parts of Mianzao, 28 parts of Arthia chinensis, 17 parts of camphor root, and 12 parts of nutmeg.

[0031] Pulverize Elephantia chinensis, arrowroot leaves, and camphor root, pass through a 100-mesh sieve, add 60% ethanol solution 15 times the mass of the three, heat and stir at 78°C for 0.9h, then heat and stir at 91°C for 1.9h, Filter to get the filtrate. Grind the jujube and nutmeg, pass through a 200-mesh sieve, add calcium hydrogen phosphate acetic acid solution of 5.5 times the mass of the two, the mass content of calcium hydrogen phosphate in the calcium hydrogen phosphate acetic acid solution is 6%, soak at 66 ° C for 3.8 hours, Stir at 112° C. for 55 minutes, and then stir at 128° C. for 12 minutes to obtain a mixed material. The filtrate is mixed with the mixed material, stirred and dried at a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum tolerated dose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com