A method for improving the high-temperature-resistant superhydrophobic performance of outdoor power equipment

A technology for outdoor power equipment and high temperature resistance, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as loss, achieve good surface performance, increase or decrease adhesion, and enhance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

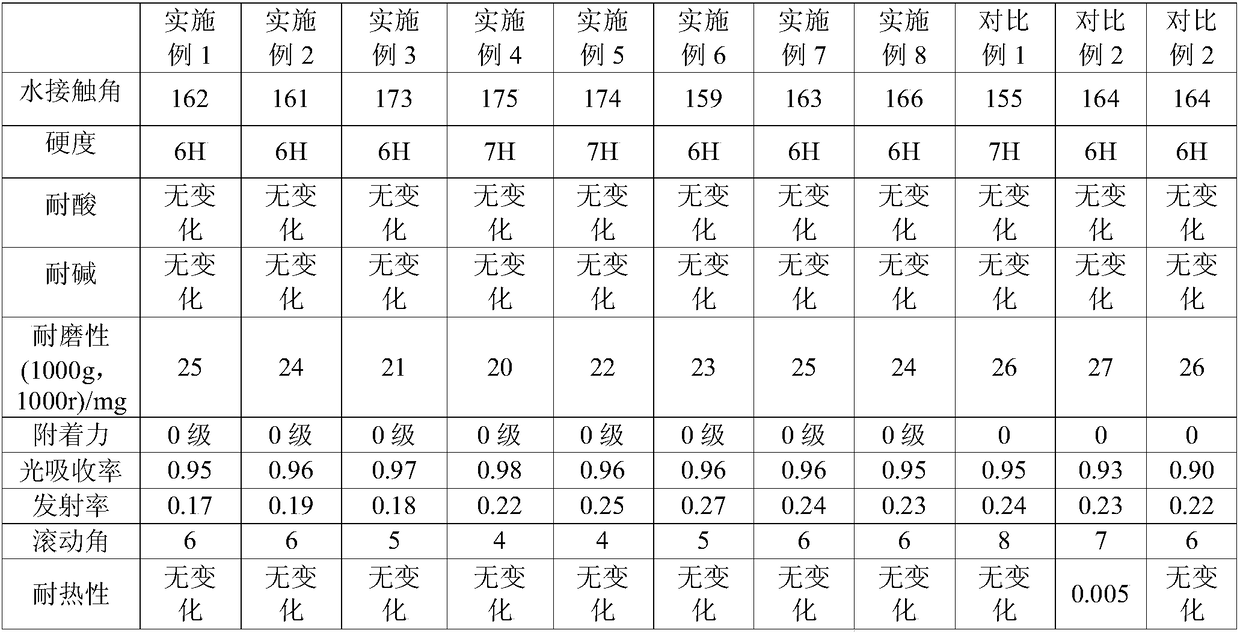

Examples

Embodiment 1

[0035] A method for improving the high-temperature-resistant superhydrophobic performance of outdoor power equipment, comprising the following steps:

[0036] 1) Pretreatment: Corona treatment is performed on the surface of the outdoor power equipment to be sprayed to activate the surface and increase the surface energy; among them, the conditions of corona treatment are: electrode gap 1 mm; treatment voltage: 5000 volts; power: 200 watt;

[0037] 2) Dilution: Dilute the high-temperature-resistant superhydrophobic nano-coating to be sprayed with 0.1 times by weight of deionized water;

[0038] 3) Spraying: Spray the diluted high-temperature resistant super-hydrophobic nano-coating in step 2) on the surface of outdoor power equipment pretreated in step 1), the pressure is 0.15MPa, the distance between the spray gun and the surface of the substrate is not less than 5 cm, and the spray gun and the surface of the substrate are in the same direction. 70° included angle.

[0039] ...

Embodiment 2

[0044] A method for improving the high-temperature-resistant superhydrophobic performance of outdoor power equipment, comprising the following steps:

[0045] 1) Pretreatment: Corona treatment is performed on the surface of the outdoor power equipment to be sprayed to activate the surface and increase the surface energy; among them, the conditions of corona treatment are: electrode gap 2 mm; treatment voltage: 15000 volts; power: 2000 watt;

[0046] 2) Dilution: Dilute the high-temperature-resistant superhydrophobic nano-coating to be sprayed with 0.2 times the weight of deionized water;

[0047] 3) Spraying: Spray the diluted high-temperature-resistant superhydrophobic nano-coating in step 2) on the surface of outdoor power equipment pretreated in step 1), the pressure is 1.5MPa, the distance between the spray gun and the surface of the substrate is not less than 5 cm, and the distance between the spray gun and the surface of the substrate is 90° included angle.

[0048] Hi...

Embodiment 3

[0053] A method for improving the high-temperature-resistant superhydrophobic performance of outdoor power equipment, comprising the following steps:

[0054] 1) Pretreatment: Corona treatment is performed on the surface of the outdoor power equipment to be sprayed to activate the surface and increase the surface energy; among them, the conditions of corona treatment are: electrode gap 1.5 mm; treatment voltage: 10000 volts; power: 1100 watt;

[0055] 2) Dilution: Dilute the high-temperature-resistant superhydrophobic nano-coating to be sprayed with 0.15 times by weight of deionized water;

[0056] 3) Spraying: Spray the diluted high-temperature-resistant superhydrophobic nano-coating in step 2) on the surface of outdoor power equipment pretreated in step 1), the pressure is 0.85MPa, the distance between the spray gun and the surface of the substrate is not less than 5 cm, and the distance between the spray gun and the surface of the substrate is 80° included angle.

[0057]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com