CsPb2Br5 nanosheet and preparation method thereof

A nanosheet, dilute solution technology, applied in chemical instruments and methods, lead compounds, inorganic chemistry, etc., can solve the problem of no nanosheet structure, and achieve the effects of uniform size, uniform crystal phase and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, CsPb 2 Br 5 Preparation of nanosheets

[0027] (1) 100mg Cs 2 CO 3 Dissolve in 3.75ml octadecene solution, then add 0.42ml oleic acid to the solution, heat at 120°C for 60min under nitrogen atmosphere, Cs 2 CO 3 Complete reaction with oleic acid to obtain cesium oleate precursor;

[0028] (2) 69mg PbBr 2 Add 5ml of octadecene solution, heat to 120°C under nitrogen, keep for 60min, raise the temperature to 135°C, inject 0.3ml of oleylamine and 0.4ml of oleic acid, to PbBr 2 Completely dissolve, then inject 0.6ml of cesium oleate precursor, and heat for 60min under nitrogen;

[0029] (3) take out reaction solution, make reaction stop completely by ice bath;

[0030] (4) Centrifuge the reaction solution at 8000rpm / s for 5min, take the precipitate, and then centrifuge and wash it three times with toluene solution. save.

Embodiment 2

[0031] Example 2, CsPb 2 Br 5 Preparation of nanosheets

[0032] (1) 100mg Cs 2 CO 3 Dissolve in 4ml octadecene solution, then add 0.47ml oleic acid to the solution, heat at 110°C for 45min under nitrogen atmosphere, Cs 2 CO 3 Complete reaction with oleic acid to obtain cesium oleate precursor;

[0033] (2) 60mg PbBr 2 Add 5ml of octadecene solution, heat to 120°C under nitrogen, keep for 60min, raise the temperature to 138°C, inject 0.3ml of oleylamine and 0.35ml of oleic acid, to PbBr 2 Completely dissolve, then inject 0.39ml of cesium oleate precursor, and heat for 90min under nitrogen;

[0034] (3) take out reaction solution, make reaction stop completely by ice bath;

[0035] (4) centrifuge the reaction solution at 8000rpm / s for 5min, take the precipitate, then centrifuge and wash it three times with n-hexane solution. stored in alkanes.

Embodiment 3

[0036] Example 3, CsPb 2 Br 5 Preparation of nanosheets

[0037] (1) 100mg Cs 2 CO 3 Dissolve in 3.7ml octadecene solution, then add 0.39ml oleic acid to the solution, heat at 135°C for 30min under nitrogen atmosphere, Cs 2 CO 3 Complete reaction with oleic acid to obtain cesium oleate precursor;

[0038] (2) 70mg PbBr 2 Add 5ml of octadecene solution, heat to 120°C under nitrogen, keep it for 60min, raise the temperature to 140°C, inject 0.3ml of oleylamine and 0.3ml of oleic acid into PbBr 2 Dissolve completely, then inject 0.5ml of cesium oleate precursor, and heat for 120min under nitrogen;

[0039] (3) take out reaction solution, make reaction stop completely by ice bath;

[0040](4) The reaction solution is centrifuged at 8000rpm / s for 5min, and the precipitate is taken, and then centrifuged and washed three times with isopropanol solution. Store in isopropanol.

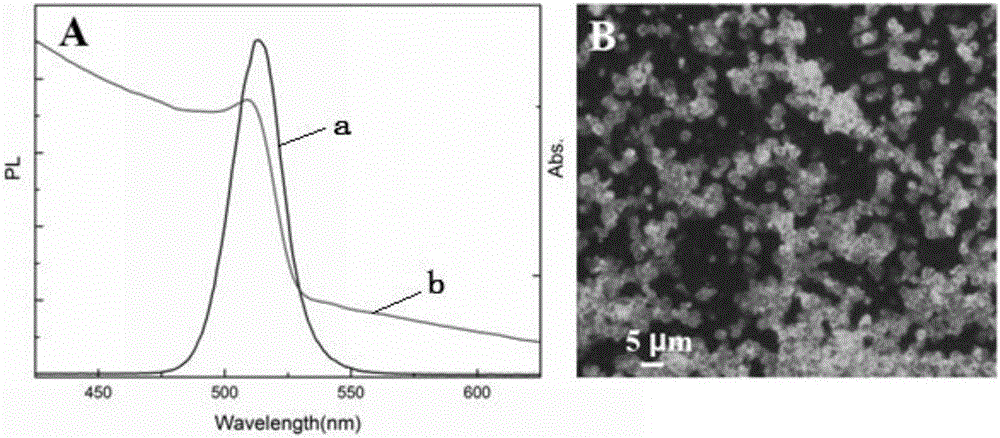

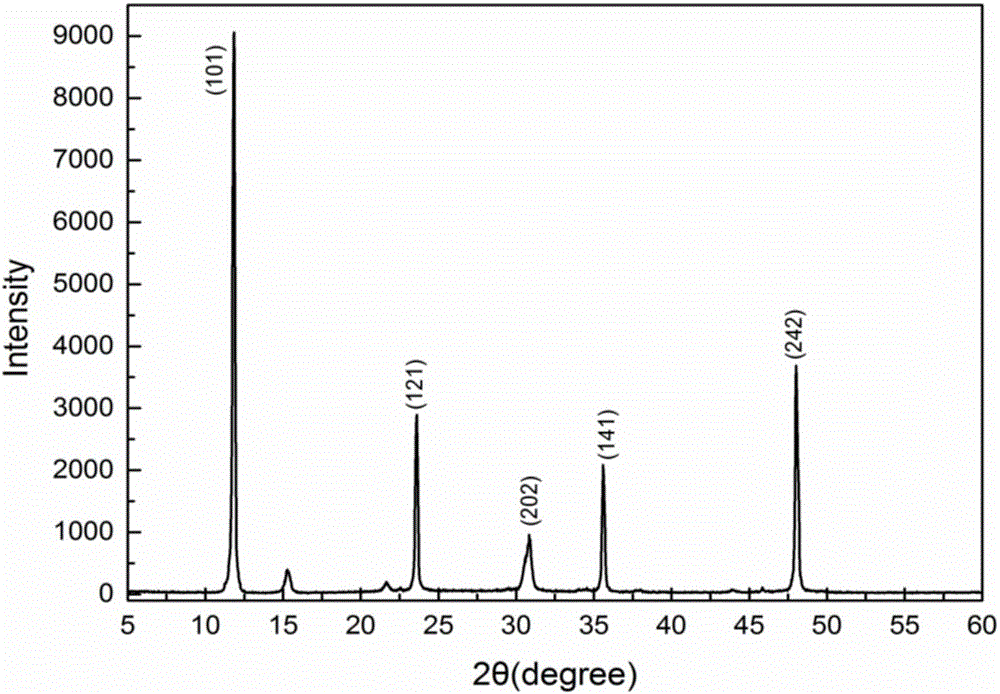

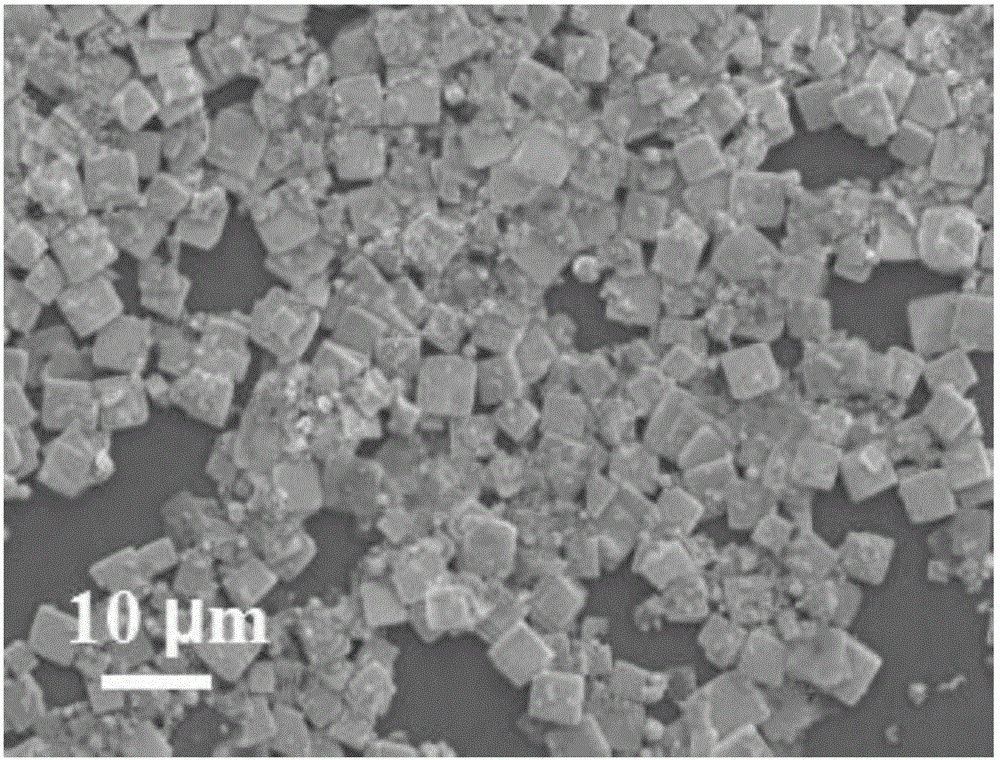

[0041] The resulting CsPb 2 Br 5 The fluorescence spectra and UV-visible absorption spectra of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com