Lithium ion battery formation method for optimizing performances of SEI membrane

A technology of lithium ion battery and formation method, which is applied in the field of lithium ion battery formation that can optimize the performance of SEI film, can solve the problems of formula taking into account, cycle performance decay, battery capacity decay, etc., so as to improve overall performance and enhance stability , the effect of dense film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

[0026] In this embodiment, the battery to be formed is a cylindrical 18650 battery, 1C=2500mA, the positive pole is nickel-cobalt lithium manganate ternary material, the negative pole is graphite, and the electrolyte is DMC / EMC / EC-LiPF 6 , Film-forming additives include FEC and VC.

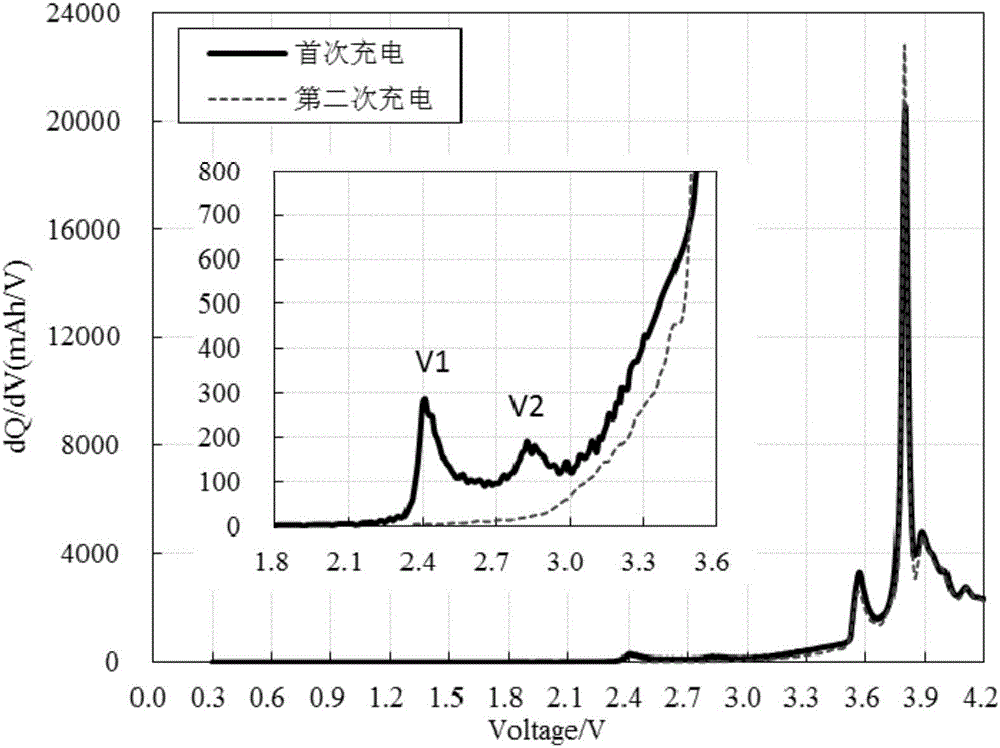

[0027] The first step is to take the battery to be formed and conduct a small current charge and discharge test, and analyze the obtained battery charge and discharge data by the capacity differential method to obtain the film formation potential at which the additive FEC and VC react, which are calculated as V1 and V2.

[0028] In this embodiment, the preferred charging and discharging current is 0.05C, that is, 125mA. The charging and discharging process is set as follows: 125mA constant current c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com