Inlaid polyaniline/H2Ti12O25 nanosheet composite material and preparation method thereof

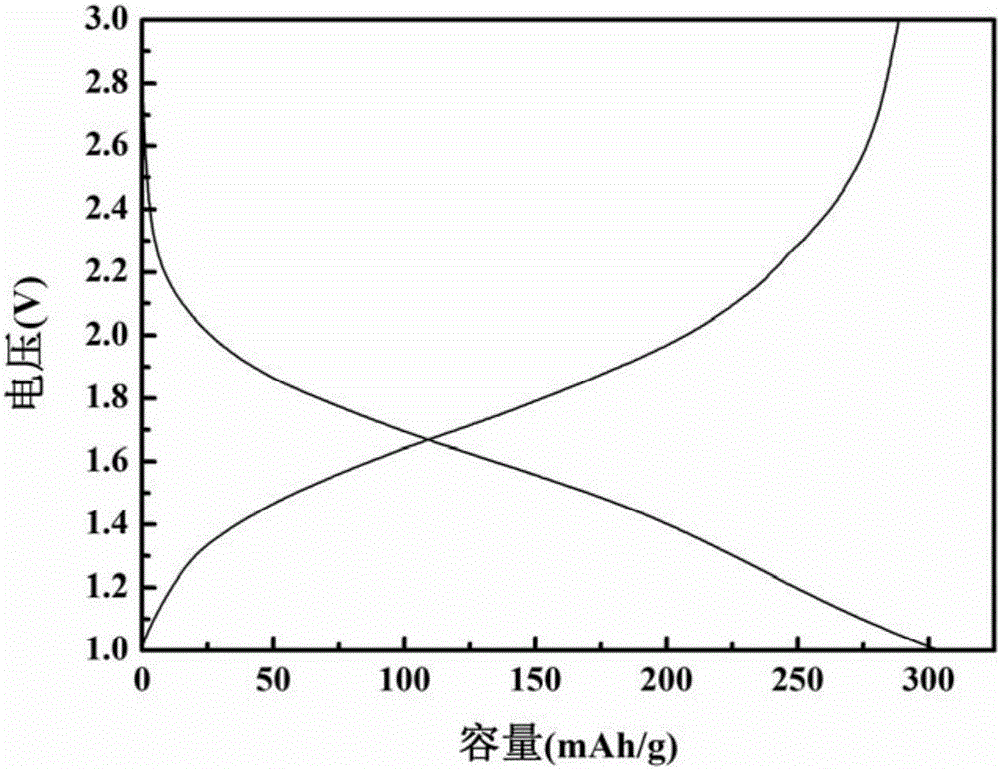

A h2ti12o25, composite material technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of poor electronic conductivity and high rate performance, and achieve the effects of good rate performance, good safety, and long cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Mosaic polyaniline / H of the present invention 2 Ti 12 o 25 A method for preparing a nanosheet composite material, comprising the steps of:

[0025] 1) With the assistance of polyols, the titanium source and the alkaline solution with a concentration of 1-6M were refluxed at 150-200°C for 6-10h to obtain Na 2 Ti 6 o 13 Nanosheet precursor;

[0026] 2) Wash Na with an acidic substance with a concentration of 0.01-0.1M 2 Ti 6 o 13 The nanosheet precursor obtained H several times 2 Ti 6 o 13 Nanosheets;

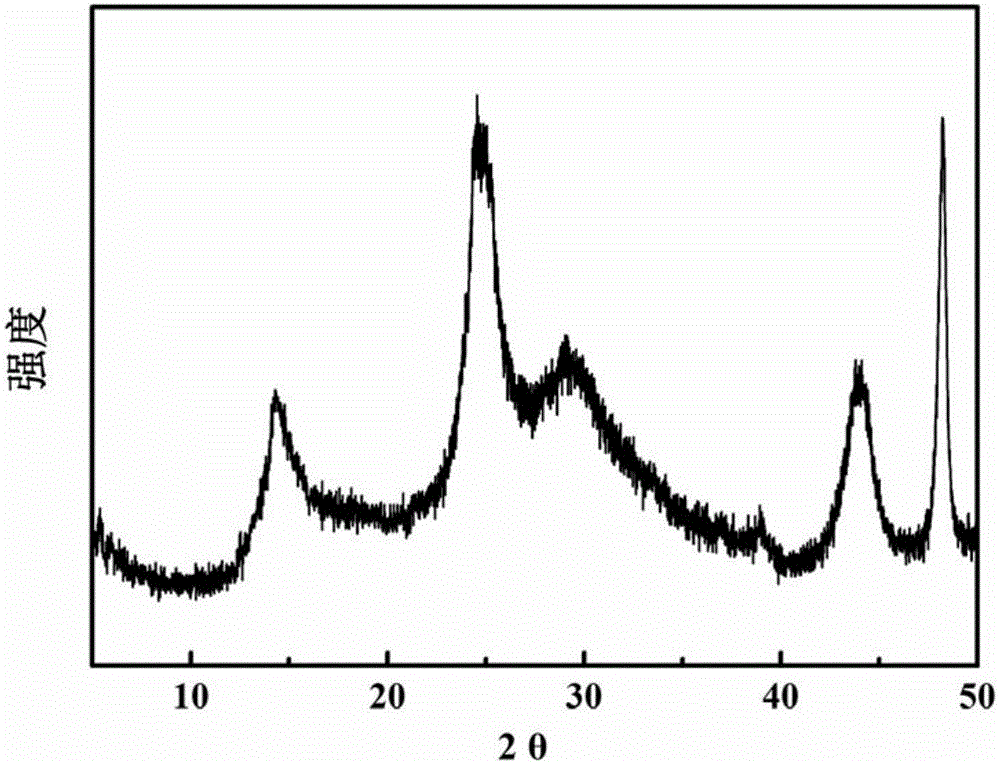

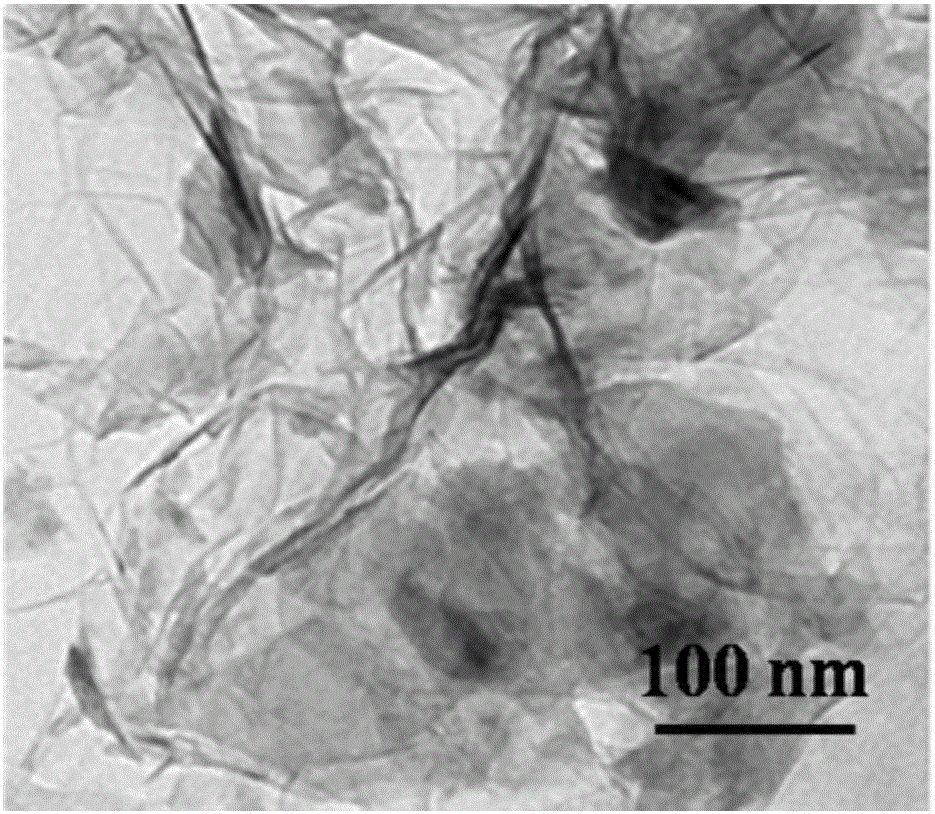

[0027] 3) put H 2 Ti 6 o 13 The nanosheets were heat-treated at 260 °C in an air atmosphere to obtain H 2 Ti 12 o 25 Nanosheets;

[0028] 4) put H 2 Ti 12 o 25 Disperse the nanosheets in 0.1-1M tetrabutylamine solution, and ultrasonicate for 6 hours at room temperature to form a suspension, in which the liquid-solid ratio is 70-300ml / g;

[0029] 5) Take a certain amount of aniline monomer and ammonium persulfate respectively, and dissolve them in 1M h...

Embodiment 1

[0037] A mosaic polyaniline / H 2 Ti 12 o 25 A method for preparing a nanosheet composite material, comprising the steps of:

[0038] 1) Dissolve 2g of polyethylene glycol-800 and 0.68g of titanium alkoxide in 48ml of ethanol solution to form a mixed solution, and reflux this solution with 24ml, 2mol / L of potassium hydroxide solution at 200°C After reacting for 6h, Na is formed 2 Ti 6 o 13 Nanosheet precursor;

[0039] 2) Wash Na with 0.01M formic acid 2 Ti 6 o 13 The nanosheet precursor obtained H 3 times 2 Ti 6 o 13 Nanosheets;

[0040] 3) Wash H with distilled water 2 Ti 6 o 13 nanosheets to remove excess formic acid, and baked at 80 °C for 24 h, followed by heat treatment at 260 °C to obtain the final product H 2 Ti 12 o 25 Nanosheets;

[0041] 4) Add 0.9g of H 2 Ti 12 o 25 The nanosheets were dispersed into 0.1M tetrabutylamine solution, and ultrasonicated for 6 hours at room temperature to form a suspension, wherein the liquid-solid ratio was 100ml / g;...

Embodiment 2

[0045] A mosaic polyaniline / H 2 Ti 12 o 25 A method for preparing a nanosheet composite material, comprising the steps of:

[0046] 1) Disperse 8g of ethylene glycol and 0.34g of rutile titanium dioxide in 48ml of ethanol solution to form a mixed solution, and react this solution with 24ml of 6M lithium hydroxide solution at 180°C for 8h to form Na 2 Ti 6 o 13 Nanosheet precursor;

[0047] 2) Wash Na with 0.05M oxalic acid 2 Ti 6 o 13 The nanosheet precursor obtained H 3 times 2 Ti 6 o 13 Nanosheets;

[0048] 3) Wash H with distilled water 2 Ti 6 o 13 nanosheets to remove excess formic acid, and baked at 80 °C for 24 h, followed by heat treatment at 260 °C to obtain the final product H 2 Ti 12 o 25 Nanosheets;

[0049] 4) Add 0.8g of H 2 Ti 12 o 25 The nanosheets were dispersed into a 0.5M tetrabutylamine solution, and ultrasonicated for 6 hours at room temperature to form a suspension, wherein the liquid-solid ratio was 200ml / g;

[0050] 5) Weigh a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com