A kind of water system rechargeable sodium ion capacitor battery and preparation method thereof

A capacitor battery, sodium ion technology, used in hybrid capacitor electrodes, hybrid capacitor electrolytes, hybrid/electric double layer capacitor manufacturing and other directions, can solve the problems of poor long-term cycle life, unfriendly environment, resource shortage, etc. Long, low cost and energy efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

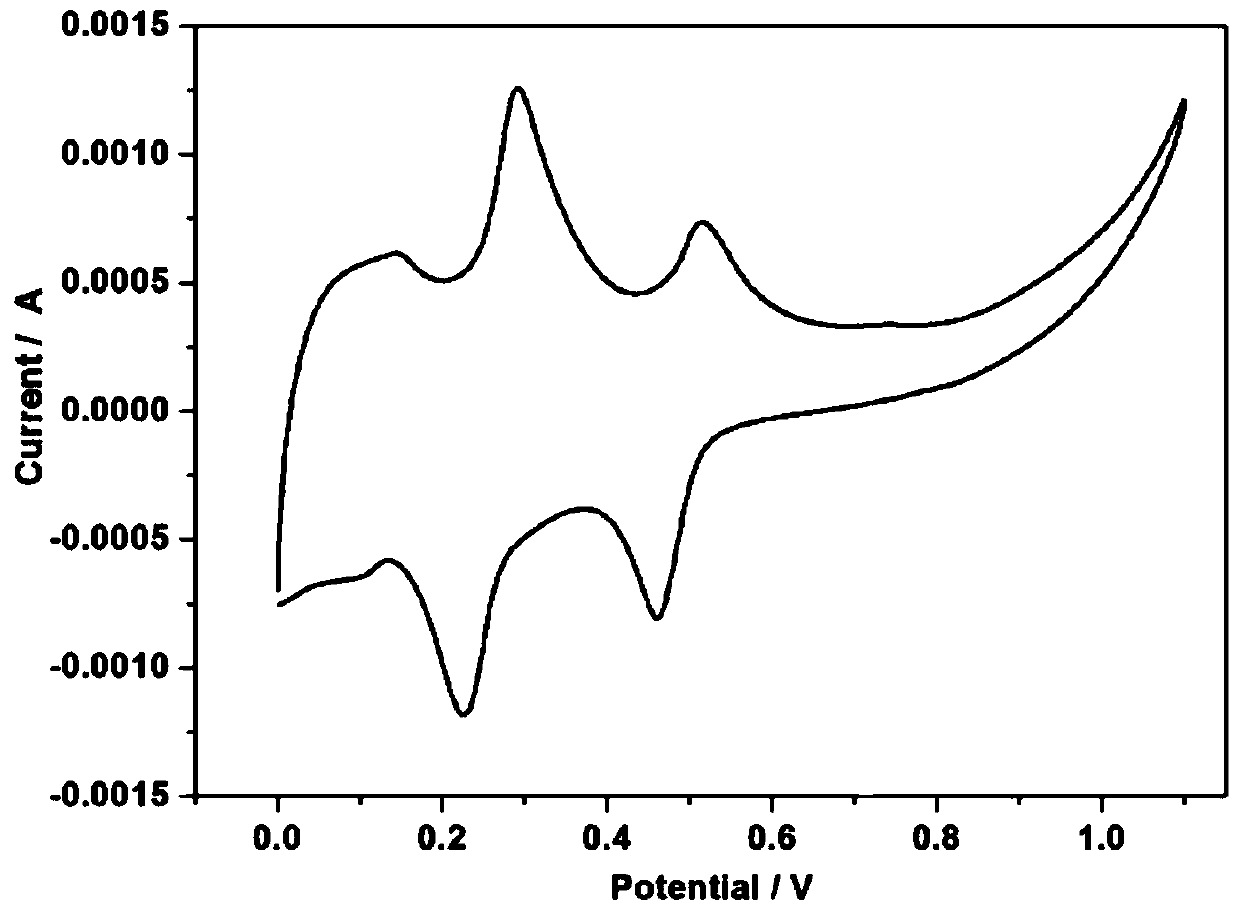

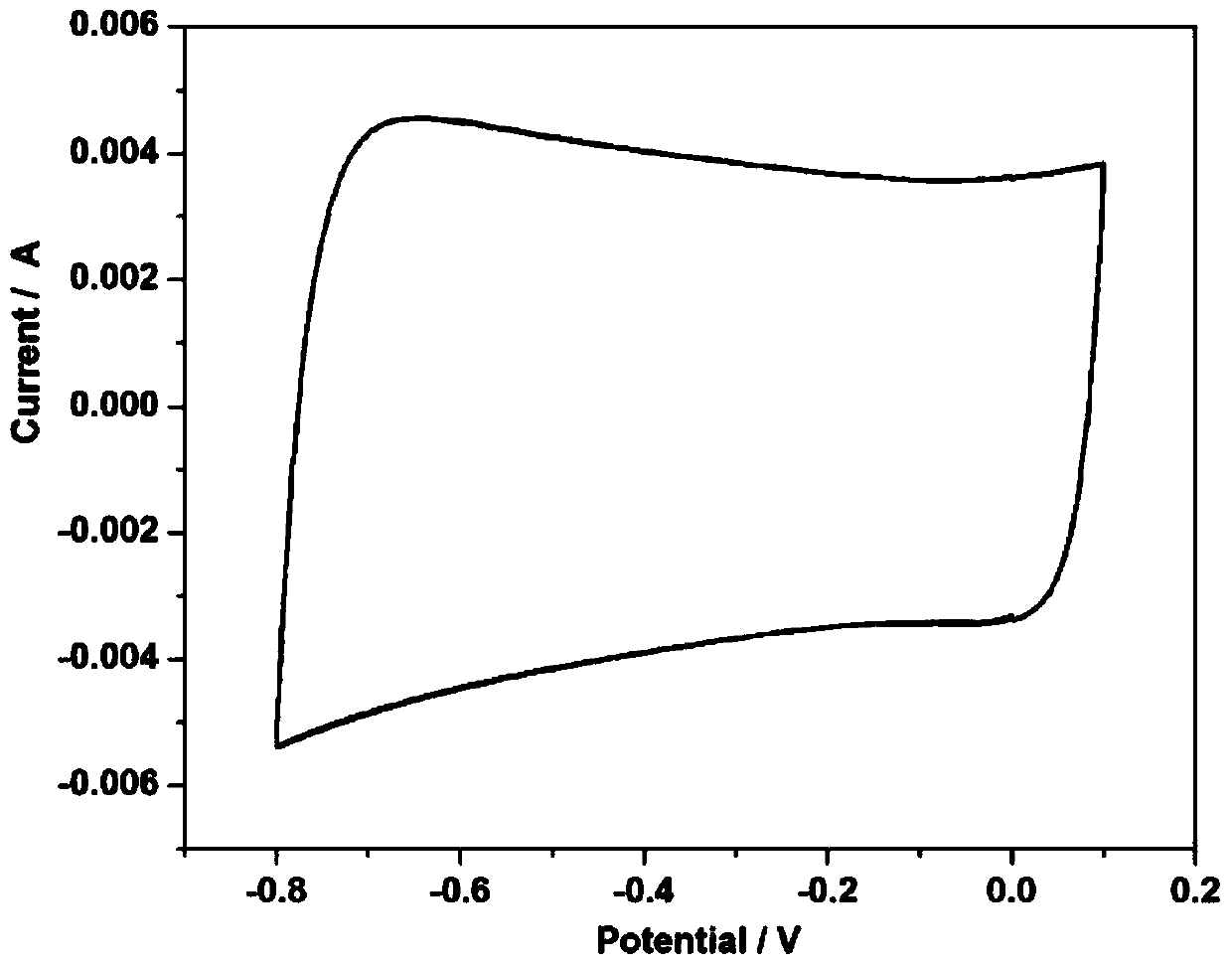

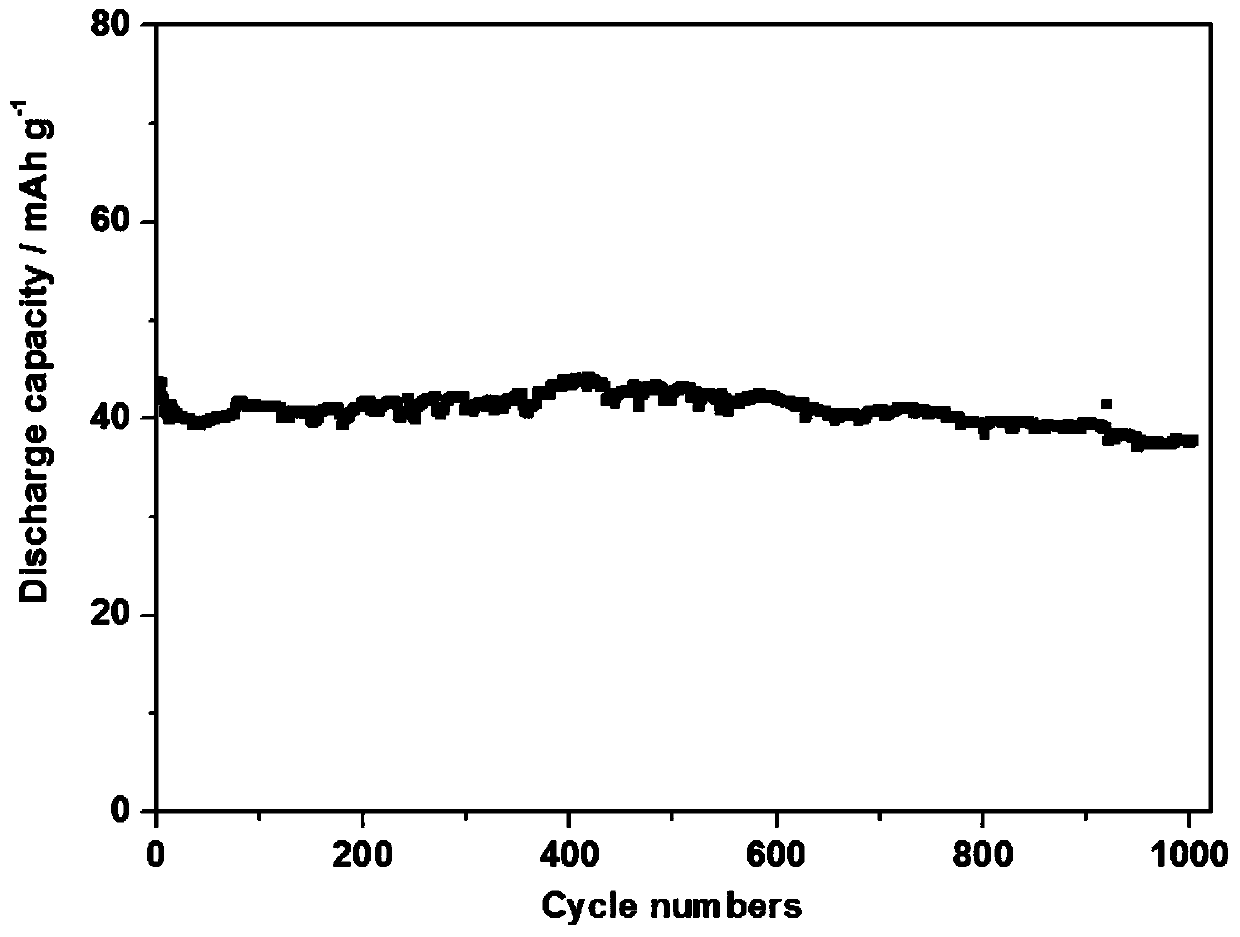

[0035] Example 1: Na 0.44 MnO 2 / Activated carbon capacitor battery assembly and performance

[0036] Na 0.44 MnO 2 Preparation of active material: MnO with a molar ratio of 1:0.22 2 and Na 2 CO 3 After grinding, pressing under 10MPa pressure, calcining in air atmosphere at 500°C for 5h, lowering to room temperature, grinding again, pressing under 10MPa pressure, calcining in air atmosphere at 900°C for 12h, after complete reaction, deionized water and anhydrous Washed with ethanol to remove miscellaneous ions, and dried in an air atmosphere at 60°C.

[0037] Positive electrode sheet preparation: add a small amount of absolute ethanol as a solvent, and Na with a mass ratio of 80:16:4 0.44 MnO 2 The active material, the acetylene black conductive agent, and the PTFE binder are mixed evenly, pressed into tablets, and dried to obtain an active positive electrode sheet.

[0038] Negative electrode sheet preparation: add a small amount of absolute ethanol as a solvent, mix...

Embodiment 2

[0044] Example 2: Na 0.44 MnO 2 / Activated carbon capacitor battery assembly and performance

[0045] Na 0.44 MnO 2 Preparation of active material: MnCO with a molar ratio of 1:0.22 3 、Na 2 CO 3 Grinding and mixing, according to NaCl and Na 2 CO 3 The molar ratio of NaCl is 23:1, adding NaCl as co-solvent, continue grinding and mixing, and calcining in air atmosphere at 850°C for 5h. Drying in medium, made.

[0046] Positive electrode sheet preparation: add a small amount of absolute ethanol as a solvent, and Na with a mass ratio of 80:16:4 0.44 MnO 2 The active material, the acetylene black conductive agent, and the PTFE binder are mixed evenly, pressed into tablets, and dried to obtain an active positive electrode sheet.

[0047] Negative electrode sheet preparation: add a small amount of absolute ethanol as a solvent, mix the commercial activated carbon material with a mass ratio of 80:16:4, acetylene black conductive agent, and PTFE binder, press into tablets, a...

Embodiment 3

[0051] Example 3: Na 0.44 mn 0.9 Li 0.1 o 2 / Mesoporous carbon capacitor battery assembly and performance

[0052] Na 0.44 mn 0.9 Li 0.1 o 2 Preparation of active material: according to the molar ratio of 1.8:0.44:0.1 MnCO 3 、Na 2 CO 3 , Li 2 CO 3 Grinding and mixing, according to NaCl and Na 2 CO 3 The molar ratio of NaCl is 23:1, adding NaCl as co-solvent, continue grinding and mixing, and calcining in air atmosphere at 850°C for 5h. Drying in medium, made.

[0053] Positive electrode sheet preparation: add a small amount of absolute ethanol as a solvent, and Na with a mass ratio of 80:15:5 0.44 mn 0.9 Li 0.1 o 2 The active material, the acetylene black conductive agent, and the PTFE binder are mixed evenly, pressed into tablets, and dried to obtain an active positive electrode sheet.

[0054] Negative electrode sheet preparation: add a small amount of absolute ethanol as a solvent, mix the mesoporous carbon material with a mass ratio of 80:15:5, acetylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com