A Visual Inspection System for Workpiece Appearance Defects Based on Image Processing

A technology of image processing and defect detection, which is applied in the field of visual inspection system, can solve the problems of high false detection of the system, poor detection of small scratches, indentations and blistering defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

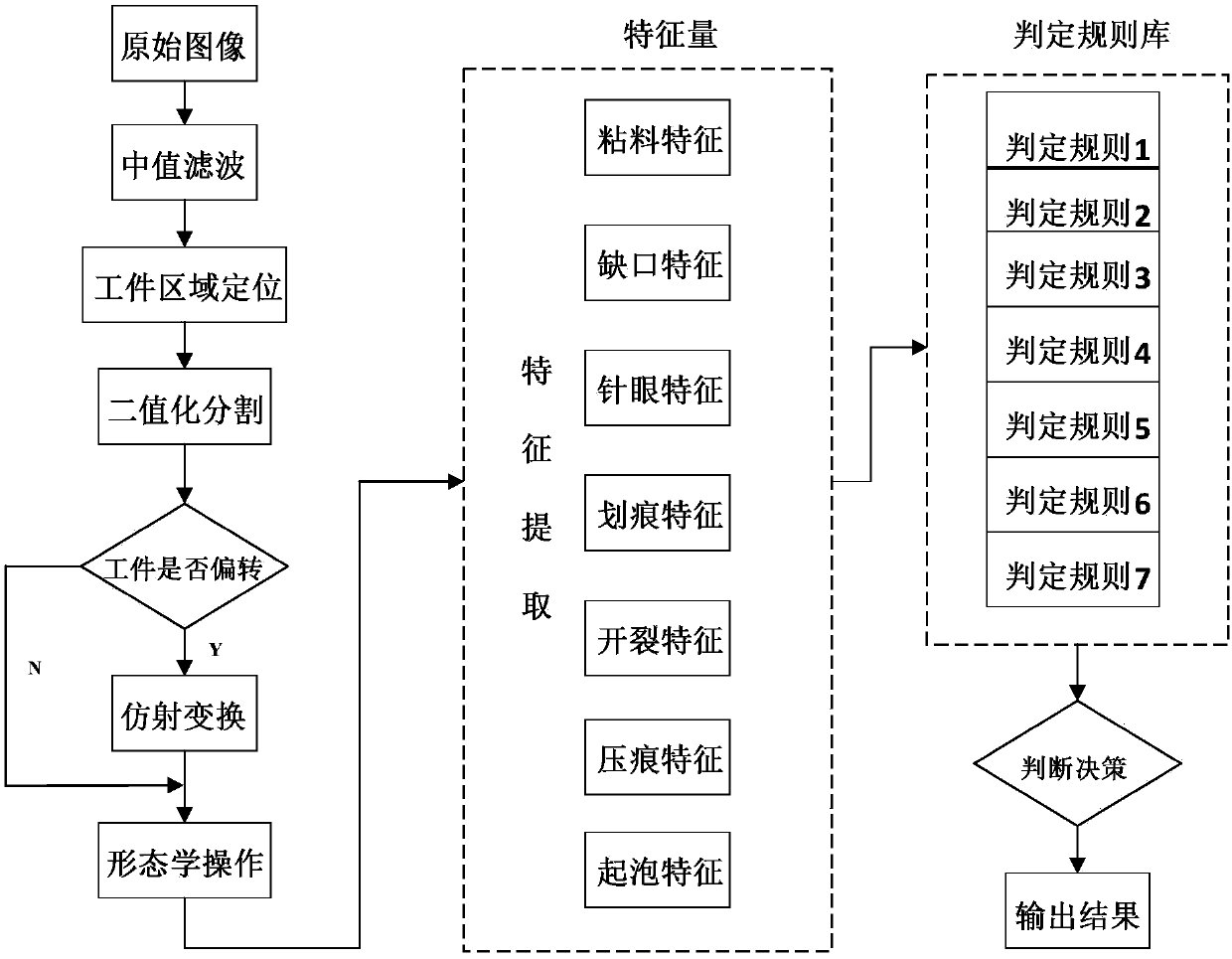

[0103] Such as Figure 1-3 , a visual inspection system for workpiece appearance defects based on image processing, characterized in that it includes an industrial computer, a coaxial light source, a CCD industrial camera, an image acquisition card and a rejecting mechanism;

[0104] Both the coaxial light source and the rejecting mechanism are connected with the industrial computer;

[0105] The CCD industrial camera is connected to the industrial computer through the image acquisition card;

[0106] Among them: the coaxial light source is used to provide diffuse reflection light source for the workpiece to be inspected; the CCD industrial camera is used to capture the image of the workpiece at the inspection station; the reject mechanism is used to remove the defective workpiece from the production line after passing the inspection;

[0107] The industrial computer has a defect detection module based on image processing;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com