Method for treating collapsible loess foundation using acid-adding presoaking method

A technology of collapsible loess and pre-soaking, which is applied in soil protection, soil material testing, infrastructure engineering, etc., and can solve the problems of ineffective treatment of the upper soil layer, poor treatment effect of pre-soaking water method, and insufficient strength of loess Strengthening and other issues, to achieve the effect of shortening the time of consolidation and drainage, high practical value and long construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Such as figure 1 A method of treating collapsible loess foundation by adding acid and presoaking water method comprises the following steps:

[0064] Step 1. Sampling: Use a soil extractor to cut a soil sample on the collapsible loess foundation to be treated;

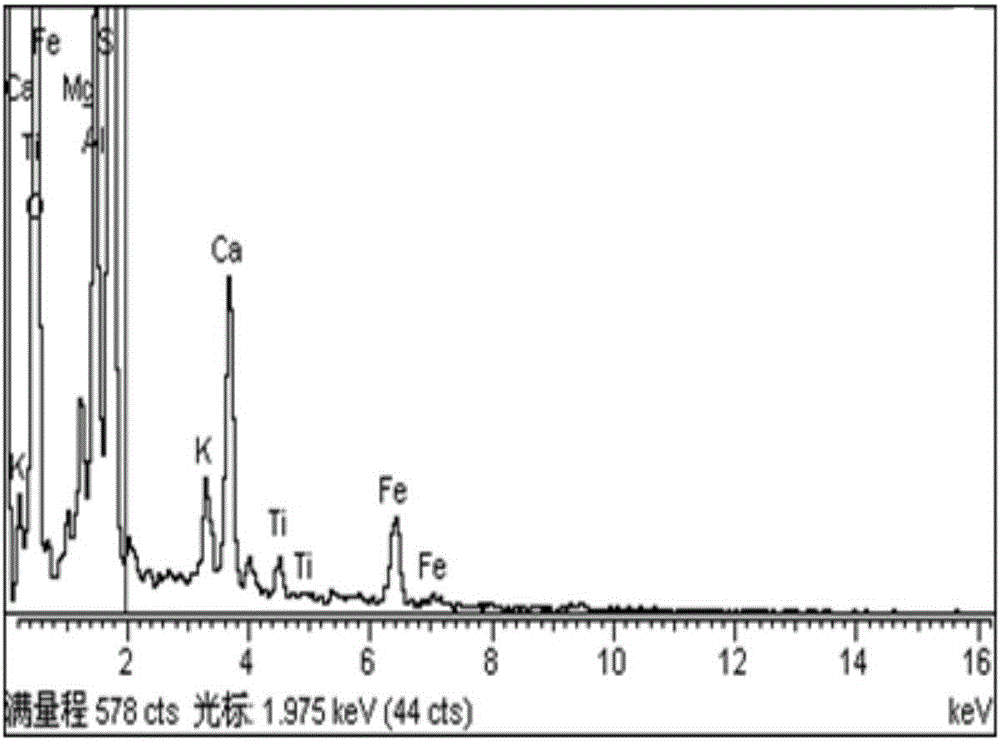

[0065] Step 2, soil sample test: first test the natural density ρ of the soil sample described in step 1, then dry the soil sample, and check the content x of calcium carbonate contained in the soil sample per kilogram after drying Test; where, the unit of ρ is kg / m 3 , the unit of x is g;

[0066] Step 3. Determine the concentration of the immersion solution: according to the formula Determining the concentration y of the immersion liquid; the immersion liquid is an acid-added aqueous solution, the acid-added aqueous solution is an acid solution formed by uniformly mixing water and acid, and the acid is a monobasic acid, a dibasic acid or a tribasic acid;

[0067] Wherein, the unit of y is mol / L; In formul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com