Method for refining grain structure of GH4169 alloy forging by adopting two-stage stepped strain rate process

A technology of GH4169 and strain rate, which is applied in the field of forging, can solve problems such as large deformation and achieve the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

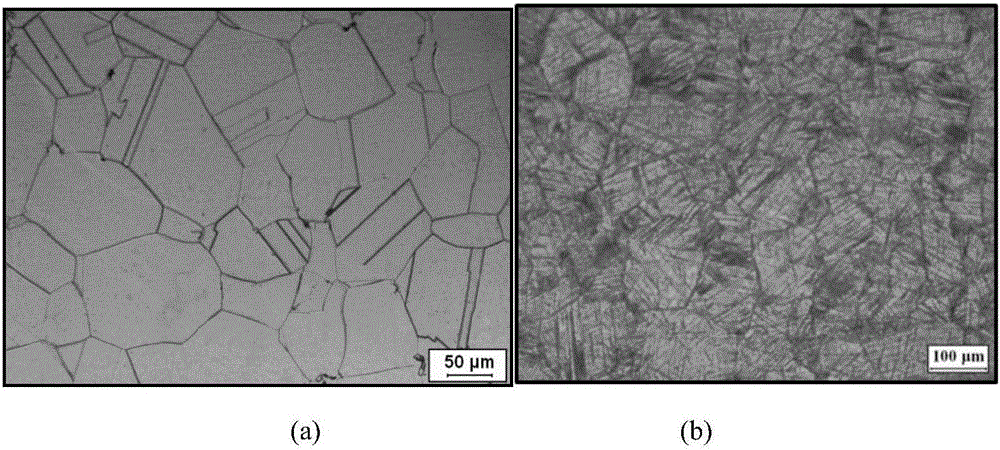

[0023] Step 1: Pretreat the GH4169 alloy forging blank. The pretreatment process is: heating the forging blank to 900°C for 24 hours, and then quenching. The structure of the GH4169 alloy forging billet after the pretreatment of step 1 is as follows: figure 1 As shown in (b), after 24 hours of pretreatment, a large number of δ phases were precipitated inside the grains.

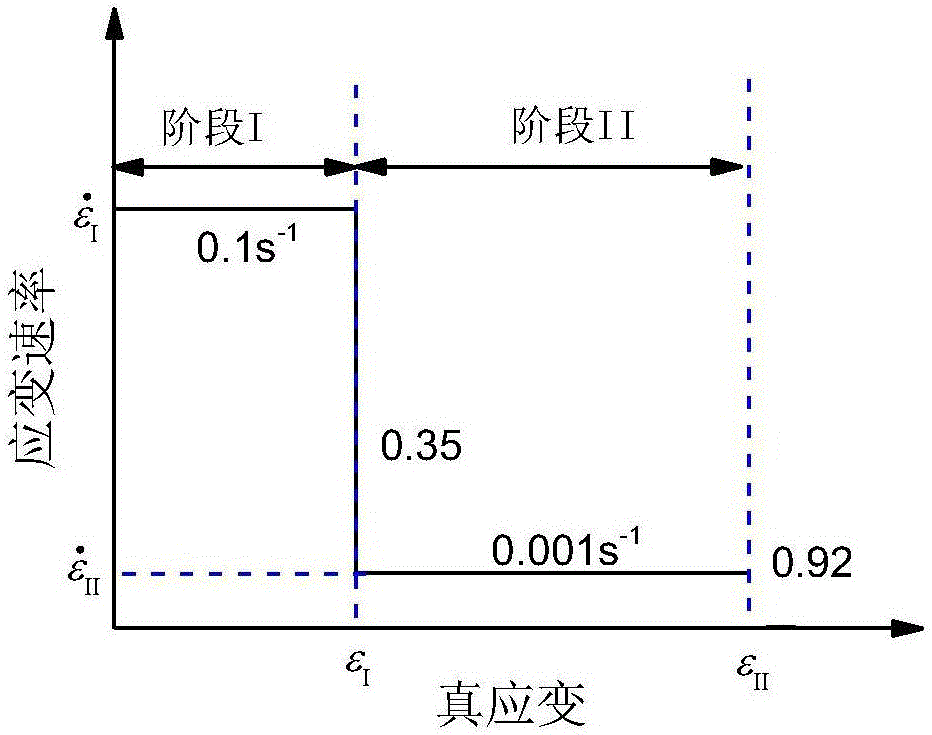

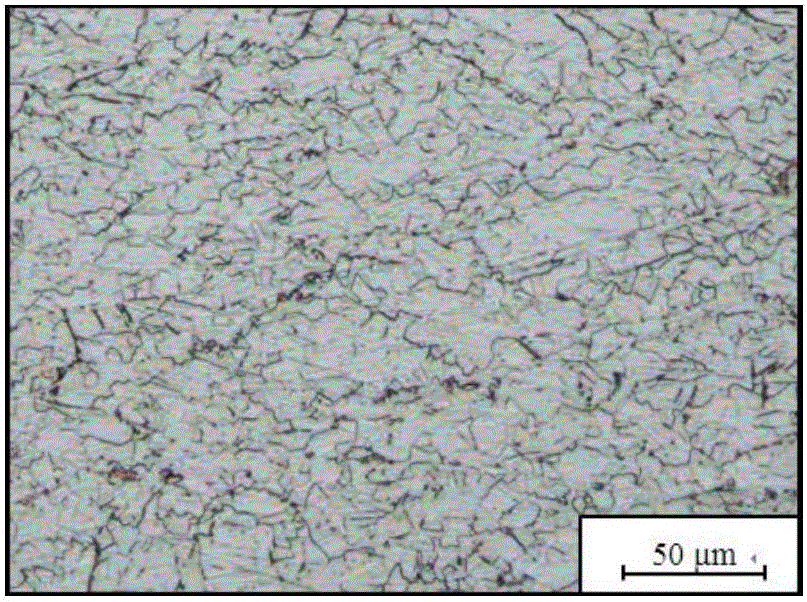

[0024] Step 2: Heat the pretreated GH4169 alloy forging billet to the deformation temperature of 980°C, keep it warm until the temperature of the forging billet is uniform, and apply deformation to the billet using a two-stage step strain rate process: the strain rate of the forging billet in the first stage is 0.1 the s -1 , the deformation of the first-stage forging billet is 30% (true strain 0.35); the strain rate of the second-stage forging billet is 0.001s -1 ; The total deformation of the forging billet after undergoing two-stage deformation is 60% (true strain 0.92). The strain rate and strain relat...

Embodiment 2

[0028] Step 1: Pretreat the GH4169 alloy forging blank. The pretreatment process is: heating the forging blank to 900°C for 24 hours, and then quenching. The structure of the GH4169 alloy forging billet after the pretreatment of step 1 is as follows: figure 1 As shown in (b), after 24 hours of pretreatment, a large number of δ phases were precipitated inside the grains.

[0029] Step 2: Heat the pretreated GH4169 alloy forging billet to the deformation temperature of 980°C, keep it warm until the temperature of the forging billet is uniform, and apply deformation to the billet using a two-stage step strain rate process: the strain rate of the forging billet in the first stage is 0.01 the s -1 , the deformation of the forging blank in the first stage is 20% (true strain 0.22); the strain rate of the forging blank in the second stage is 0.001s -1 , the total deformation of the forging billet after two-stage deformation is 50% (true strain 0.7); the relationship between the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com