Power cable for solar photovoltaic power distribution cabinet

A solar photovoltaic and power cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of unable to meet the special use requirements of photovoltaic power distribution cabinets, and achieve the effect of soft texture, improved performance, and superior flame retardant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

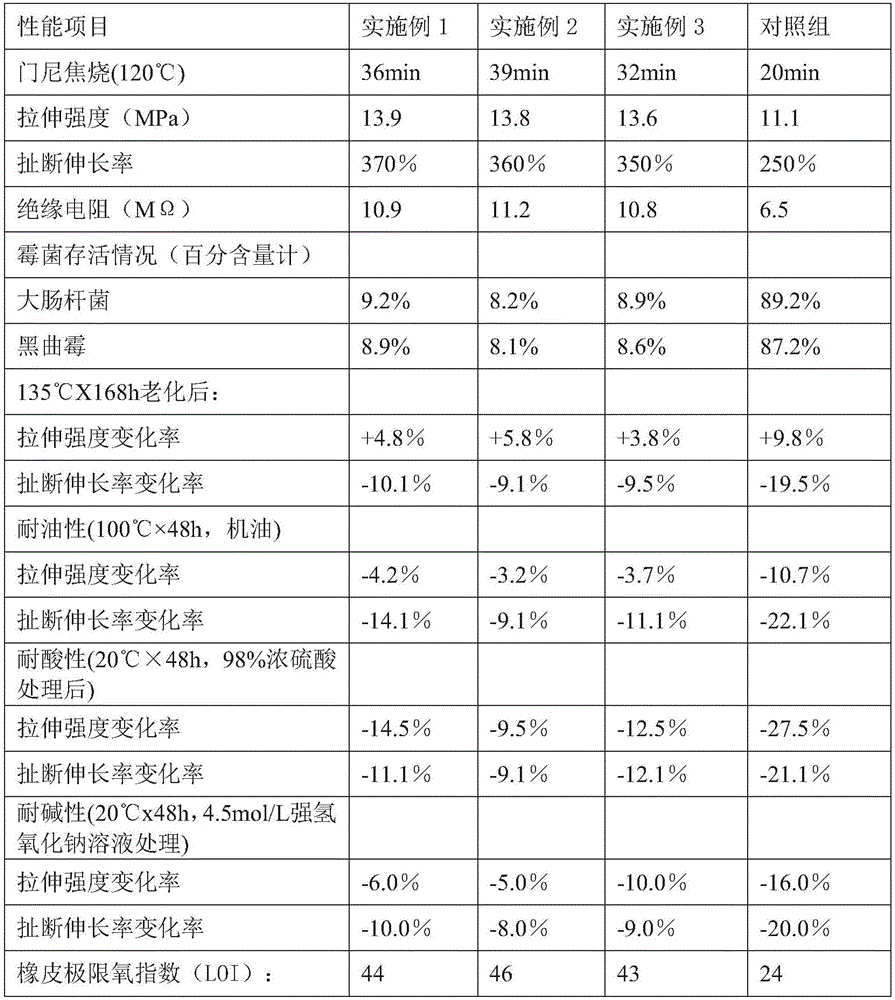

Embodiment 1

[0017] The power cable for the solar photovoltaic power distribution cabinet in this embodiment includes a plurality of copper alloy wires and protective sleeves, the copper alloy wires are placed parallel to each other, and the outer layer of each copper alloy wire is covered with a protective sleeve, and the protective sleeve is made of The following components are composed in parts by mass: 12 parts of polybutylene terephthalate, 10 parts of ethylene propylene rubber, 10 parts of isoprene rubber, 8 parts of ethylenediamine tetramethylene phosphonic acid, and 10 parts of dimethylformamide 10 parts of cottonseed oil, 8 parts of phosphate ester, 10 parts of eucalyptus oil, 10 parts of Blopol, 8 parts of garlic oil, 8 parts of tea polyphenols, 8 parts of porcelain powder, 10 parts of zeolite powder, and 8 parts of lead oxide powder 6 parts of soda ash, 10 parts of calcium phosphate powder, 8 parts of vermiculite powder, 6 parts of dolomite powder, 8 parts of honey, 6 parts of po...

Embodiment 2

[0024] The power cable for the solar photovoltaic power distribution cabinet in this embodiment includes a plurality of copper alloy wires and protective sleeves, the copper alloy wires are placed parallel to each other, and the outer layer of each copper alloy wire is covered with a protective sleeve, and the protective sleeve is made of The following components are composed in parts by mass: 14 parts of polybutylene terephthalate, 12 parts of ethylene propylene rubber, 12 parts of isoprene rubber, 10 parts of ethylenediamine tetramethylene phosphonic acid, and 12 parts of dimethylformamide 12 parts of cottonseed oil, 10 parts of phosphate ester, 12 parts of eucalyptus oil, 12 parts of Blopol, 10 parts of garlic oil, 10 parts of tea polyphenols, 10 parts of porcelain powder, 12 parts of zeolite powder, 10 parts of lead oxide powder 8 parts of soda ash, 12 parts of calcium phosphate powder, 10 parts of vermiculite powder, 8 parts of dolomite powder, 10 parts of honey, 8 parts o...

Embodiment 3

[0031] The power cable for the solar photovoltaic power distribution cabinet in this embodiment includes a plurality of copper alloy wires and protective sleeves, the copper alloy wires are placed parallel to each other, and the outer layer of each copper alloy wire is covered with a protective sleeve, and the protective sleeve is made of The composition of the following parts by mass: 16 parts of polybutylene terephthalate, 14 parts of ethylene propylene rubber, 14 parts of isoprene rubber, 12 parts of ethylenediamine tetramethylene phosphonic acid, 14 parts of dimethylformamide 14 parts of cottonseed oil, 12 parts of phosphate ester, 14 parts of eucalyptus oil, 14 parts of Blopol, 12 parts of garlic oil, 12 parts of tea polyphenols, 12 parts of porcelain powder, 14 parts of zeolite powder, 12 parts of lead oxide powder 10 parts of soda ash, 14 parts of calcium phosphate powder, 12 parts of vermiculite powder, 10 parts of dolomite powder, 12 parts of honey, 10 parts of polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com