[0002]

Natural rubber is widely planted in the

tropics of our country, and the existing rubber harvesting is facing a serious problem, because most of the planting of rubber trees are distributed in the mountains, and some rubber farmers live in remote areas , the traffic in these areas is extremely inconvenient. At the same time, due to the abundant rainfall in the tropical climate, landslides often occur on the road, which further affects the local traffic. It is especially important to keep the latex harvested from the rubber tree stable. The best way is to sell it to the rubber

processing factory in time. A preliminary processing treatment, so that the white gel rubber block with better quality can be obtained. The good quality white gel rubber block not only has good physical and chemical properties of the rubber itself, but it is difficult for a large number of harmful microorganisms in latex due to timely processing.

Reproduction, the large number of harmful microorganisms will cause the latex to emit a bad smell, but also because the microorganisms consume the

protein and

sugar in the latex to reduce the physical and chemical properties of the white gel block, and the latex that cannot be processed in time will deteriorate, especially when the temperature is relatively low. especially prominent at high

In the existing technology, the rubber farmers directly place it in the carrying cup, and after several days of natural coagulation, they obtain "pastoral cup glue". These "pastoral cup glue" have a strong

odor. It has a great

impact on the surrounding environment. At the same time, these "pastoral cup glue" are decomposed by a large number of microorganisms to the

protein and

sugar contained in the latex, and a large amount of acidic substances are produced, which leads to the performance of the "pastoral cup glue". The reduction also makes the price of "pastoral cup glue" drop

[0003] Then the natural coagulation of latex brings so many adverse consequences. If the latex is not allowed to coagulate naturally, this problem seems to be solved. The coagulation of latex refers to the process of transforming latex from a

stable state to its opposite under certain conditions. In other words, coagulation It is the process of destroying stability, and fresh-keeping is the process of maintaining stability. Long-term fresh-keeping refers to maintaining the stability of latex for a long time. The fresh latex just discharged from the rubber tree has a pH of about 7.0, which is higher than the

isoelectric point of protein. Therefore, the protein in the protective layer of the rubber particles is acid-ionized, which makes the surface of the rubber ions negatively charged, thereby causing the polarization of the surrounding water molecules, generating induced dipoles and directional arrangement on the surface of the rubber particles to form a layer of hydration. Therefore, to make the latex coagulate, it is necessary to destroy these two characteristics of the rubber particles, that is to say, to neutralize the charge on its surface or to destroy its hydration film. Almost all coagulation methods are based on this point, on the contrary The fresh-keeping technology is to protect the charge or hydration film on its surface. There are a large number of microorganisms in nature, which means that microbial

parasitism is inevitable during the long-term storage of latex, and the metabolites produced by some parasitic microorganisms The acidic substances or other metabolites produced in the process will destroy the

surface charge or destroy the hydration film, which naturally leads to the coagulation of the latex. During the coagulation process, the rubber has an

odor due to the presence of some microbial metabolites.

odor, and the

reproduction of microorganisms decomposes a large amount of protein and

sugar, which leads to the decline in the quality of the latex after solidification, so we need to keep the latex fresh, whether it is when there is excess material accumulation in large enterprises or remote areas that cannot be transported out for sale in time When we all need latex preservation technology

[0004] The prior art also has the method of adding 0.2-0.7 parts of

ammonia water, 1-1.5 parts of

potassium ferrocyanide, 0.3-0.5 parts of

sodium metabisulfite, 0.1-0.3 parts of

ethylparaben, 0.2-0.3 parts of nipagin for the preservation of latex. Parkin propyl ester, 0.3-0.5 parts of

sodium bicarbonate, 1-3 parts of

sodium citrate and other organic or

inorganic chemical preparations to achieve freshness preservation. In this freshness preservation method, firstly, the quality of rubber decreases, and secondly, it still cannot Eliminate the invasion and

parasitism of microorganisms. In the theory of microorganisms, there is a theory that

beneficial bacteria expel harmful

bacteria. Since harmful

bacteria cannot be completely eliminated, why don't we introduce bacteria that are beneficial to latex to keep fresh? The introduction will not change the pH value At the same time, it will not lead to the reduction of

negative charge, and will not destroy the

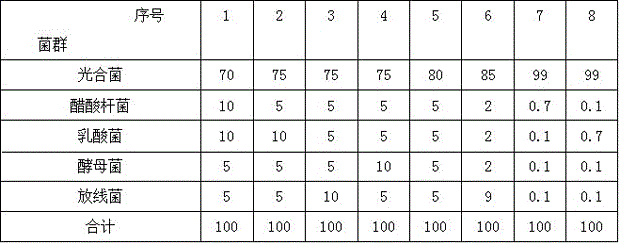

beneficial bacteria flora of the hydration film

[0005] In the face of such problems, researchers have not proposed a suitable technology, and some have proposed the use of microbial preservation technology to let rubber farmers in remote areas or enterprises that cannot process in time add microorganisms that will not cause a large amount of odor to the manual latex. Realize the coagulation of latex, so that the rubber farmers in remote areas can obtain good quality "pastoral cup glue". For fresh latex that cannot be processed in time, the company can also keep fresh for a long time. Second, it does not produce low-quality It will not produce a lot of peculiar smell during solidification, but the effect is not obvious in actual operation. The principle is that the added live bacteria expel unnecessary bacteria due to the large number of

reproduction, so as to realize the deodorization of rubber, but this technology is only It is just to obtain a white gel block with a bottom odor that can solidify quickly. After all, the processing technology of rubber farmers and small enterprises is not as good as that of large enterprises. Farmers don’t allow it to coagulate, or in other words, when we need to coagulate these latexes, we can add certain materials or bacteria to these fresh-keeping latexes to quickly coagulate. When these latexes are not required to coagulate, these latexes can maintain the chemical properties close to fresh latex Or physical properties, there is no obvious quality difference between latex processed to obtain

natural rubber and fresh latex processed in time to obtain

natural rubber after long-term preservation, and there is no difference in other physical or chemical properties. This is the real meaning fresh-keeping, but there is no prior art in this field in the prior art, and what the prior art preserves is still the latex after coagulation, rather than the liquid uncoagulated latex

[0006]

Chinese patent with patent number CN201210003101.5, a biological deodorization method of natural rubber fresh latex biogel block, which involves adding the

test tube slant culture of strain C1 to clear water containing 5wt% sugar, and shaking it at 28-35°C The biological

deodorant liquid obtained by culturing for 2 to 3 days is mixed into the biological coagulation liquid at a weight ratio of 1:10 to 1:1 to coagulate fresh latex, that is, a

deodorant with long-lasting activity is added at the coagulation stage of fresh latex , to suppress the generation of odor from the source, so that the gelatinous block will not emit odor due to the presence of active

deodorant during storage and processing, and reduce the release of odor during the

drying process of the standard glue. This patented technology A method of deodorizing microbial strains is given, that is, when the fresh latex is coagulated, the bacterial culture solution containing the C1 strain is added to achieve coagulation and deodorization. The patented technology still does not realize that no matter what strains are added The number of strains is not the

root cause of fresh latex odor and the decline in fresh latex quality. The added bacteria do not need to decompose or decompose nutrients such as protein and sugar in fresh latex as little as possible while still ensuring rapid proliferation of bacteria. It is the key to ensure that fresh latex can coagulate quickly and obtain high-quality white gel blocks. It can also effectively deodorize, and the preparation process of the bacterial solution needs to be simple and convenient, because rubber farmers in remote areas and latex purchases in remote areas It is difficult for point or small

processing plants to meet the requirements of complex processes

[0007] In the prior art, as described in the

reference document above, by making fresh latex and an external

nutrient source together into a culture medium suitable for microbial life in whey, although the coagulation speed has been greatly improved, the quality of the obtained white

gelatin block has been greatly reduced. It was only then that people realized that the greater the number of microorganisms, the more problems they caused. The increase in the number of bacteria converts more sugars into fatty acids. These fatty acids will greatly reduce the pH of the latex, and eventually cause the hydration film of the latex to become thinner. , the overall stability of the latex decreases, and at the same time a large number of bacteria will decompose the protein in the latex. After the protein is decomposed, the protective layer of the colloidal particles is destroyed, the

negative charge of the colloidal particles is reduced, the hydration film is thinner, the elasticity and

pressure resistance is reduced, and the

potential energy peak is decreased. , eventually further deepening the reduction of the latex stability

[0008] The

added sugar and other exogenous nutrients will only bring more exogenous impurities in the latex, and the

added sugar will also bring a large amount of fatty acids after being decomposed in large quantities, and the appearance of fatty acids will bring about -COOH

decomposition. Liberation is inhibited, -NH 2 The dissociation is enhanced, the

negative charge of the colloidal particles is reduced, and the final result is still a decrease in the stability of the latex. Therefore, in production, an appropriate amount of bacteria, enzymes or sugar substances in the latex in the latex will indeed accelerate the natural coagulation of the latex, but the external The more substances added, the more impurities are added, the more ash content of the rubber, and the worse the quality. In order to keep the latex in a

stable state under the existing technology, it is necessary to inhibit the growth of bacteria and enzymes. active

Login to View More

Login to View More  Login to View More

Login to View More