Synthesis device and process of 2-ethylanthraquinone

An ethyl anthraquinone and synthesis device technology, applied in the field of anthraquinone derivatives synthesis device, can solve the problems of reduced production efficiency, rising reaction temperature, exceeding the reaction temperature, etc., so as to reduce safety accidents, avoid safety accidents, and increase continuous sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

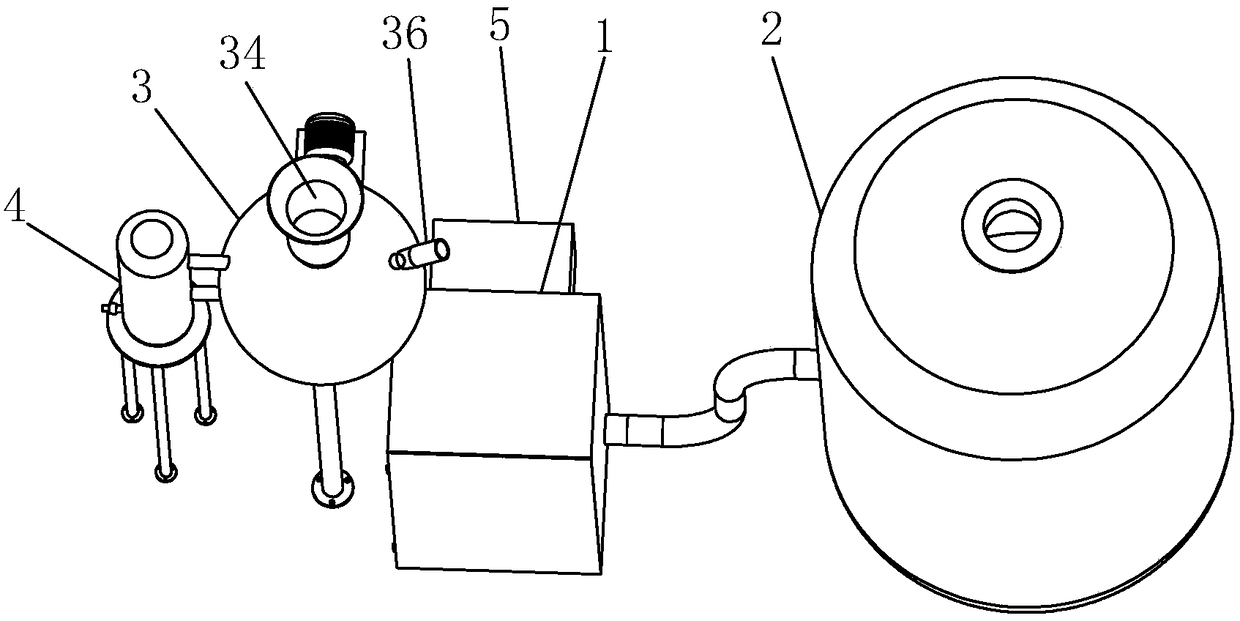

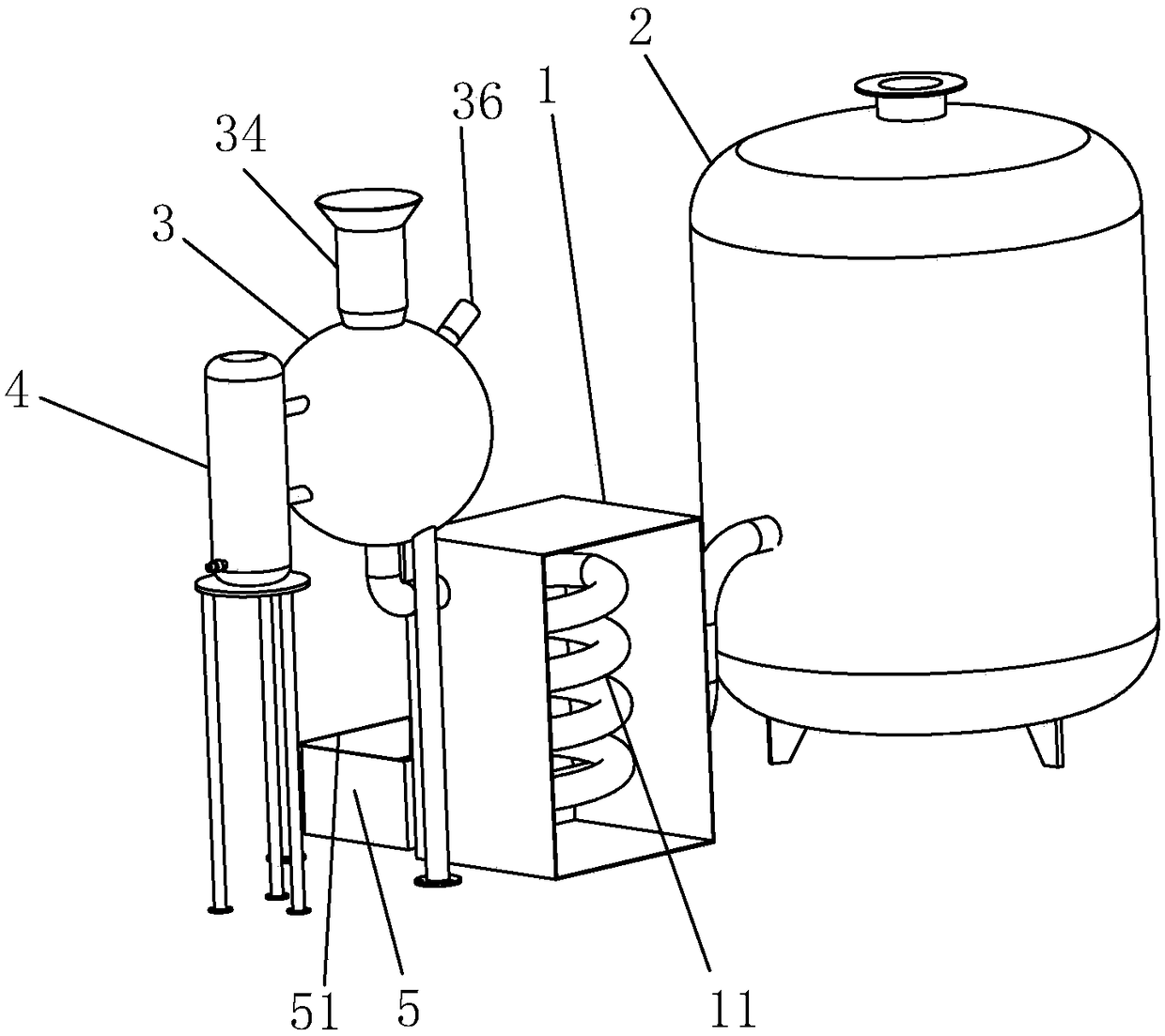

[0042] A kind of synthetic device of 2-ethylanthraquinone, refer to figure 1 Shown, comprise the spherical mixer 3 that carries out thorough mixing between materials, the tubular reactor 1 that the material after mixing carries out chemical reaction and the hydrolysis still 2 that separates out 2-ethylanthraquinone through reaction liquid, spherical mixer 3 also A condenser 4 is connected to cool the spherical mixer 3. The mixing process of this kind of synthesis device is peaceful and stable, and the temperature of the reaction process can be controlled at 120-160°C, ensuring that the 2-ethylanthraquinone prepared by the synthesis device The process has good stability and high safety, and the prepared 2-ethylanthraquinone has stable and uniform performance.

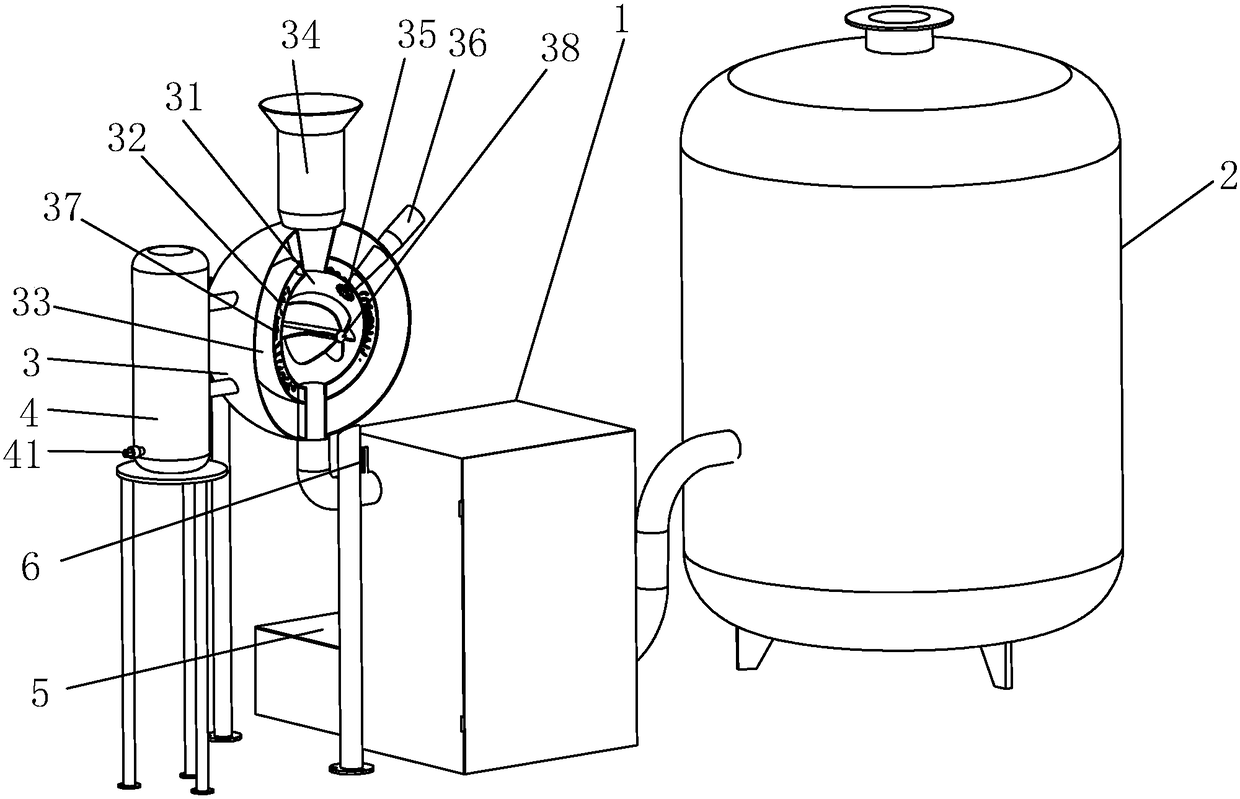

[0043] refer to figure 2 As shown, the spherical mixer 3 is in the shape of a sphere, including an inner chamber 31, a middle chamber 32 arranged around the inner chamber 31, and an outer chamber 33 arranged around the...

Embodiment 2

[0047] (1) Add 100 parts by mass of solid raw material 2-(4-ethylbenzoyl)benzoic acid into the spherical mixer, add 100 parts by mass of fuming sulfuric acid into the liquid inlet pipe, heat the spherical mixer, and wait for the solid raw material 2-(4-Ethylbenzoyl)benzoic acid becomes fluid, and the two are fully mixed under stirring;

[0048] (2) Open the condenser, control the water flow into the condenser, and control the temperature of the mixed material flowing out of the spherical mixer to 125°C;

[0049] (3) The materials mixed by the spherical mixer flow into the tubular reactor for reaction;

[0050] (4) The material flowing out of the tubular reactor enters the hydrolysis tank for hydrolysis, and the product 2-ethylanthraquinone is precipitated.

Embodiment 3

[0052] (1) Add 100 parts by mass of solid raw material 2-(4-ethylbenzoyl)benzoic acid into the spherical mixer, add 200 parts by mass of fuming sulfuric acid into the liquid inlet pipe, heat the spherical mixer, and wait for the solid raw material 2-(4-Ethylbenzoyl)benzoic acid becomes fluid, and the two are fully mixed under stirring;

[0053] (2) Open the condenser, control the water flow into the condenser, and control the temperature of the mixed material flowing out of the spherical mixer to 135°C;

[0054] (3) The materials mixed by the spherical mixer flow into the tubular reactor for reaction;

[0055] (4) The material flowing out of the tubular reactor enters the hydrolysis tank for hydrolysis, and the product 2-ethylanthraquinone is precipitated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com