Fertilizer prepared from fermentation residues of plant-fermented enzyme beverages

An enzyme beverage and plant fermentation technology, applied in the field of agricultural fertilizers, can solve problems such as waste of resources, and achieve the effects of increasing yield, avoiding waste of resources and reducing morbidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

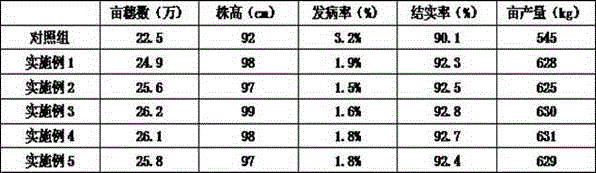

Examples

Embodiment 1

[0021] A kind of fertilizer that utilizes the fermentation residue of plant fermented enzyme beverage to prepare, is made up of following raw material according to weight part: plant fermented enzyme beverage fermented residue 85 parts, humic acid 42 parts, poultry manure 50 parts, urea 13 parts, phosphoric acid 10 parts of urea, 6 parts of potassium sulfate, 8 parts of superphosphate, 5 parts of trace element fertilizer, 3 parts of ascorbic acid, 1 part of n-butyl triamine thiophosphate, 7 parts of deer marsh soil, 9 parts of saponins, 6 parts of pyrethrum, 3 parts of making gentleman, 8 parts of purslane, 2 parts of Fructus Cnidii, 2 parts of JT compound strain, 4 parts of 5406 strain powder; Described trace element fertilizer is made up of following raw material according to weight part: borax 10 6 parts of manganese sulfate, 12 parts of copper slag, 3 parts of cobalt fertilizer, 5 parts of ammonium molybdate, 7 parts of sodium selenite, 2 parts of zinc sulfate, and 3 parts ...

Embodiment 2

[0030] A kind of fertilizer that utilizes the fermented residue of plant fermented enzyme beverage to prepare, is made up of following raw material according to weight part: plant fermented fermented fermented beverage fermented residue 86 parts, humic acid 45 parts, poultry feces 52 parts, urea 17 parts, phosphoric acid 11 parts of urea, 6 parts of potassium sulfate, 10 parts of superphosphate, 8 parts of trace element fertilizer, 3.5 parts of ascorbic acid, 1.5 parts of n-butyl triamine thiophosphate, 8 parts of deer marsh soil, 12 parts of saponins, 6 parts of pyrethrum, 4 parts of Gentleman, 8 parts of purslane, 4 parts of Fructus Cnidii, 5 parts of JT composite strains, 5 parts of 5406 strains powder; Described trace element fertilizer is made up of following raw material according to weight part: borax 11 7 parts, manganese sulfate 7 parts, copper slag 15 parts, cobalt fertilizer 4 parts, ammonium molybdate 5 parts, sodium selenite 8 parts, zinc sulfate 4 parts, ferrous s...

Embodiment 3

[0039] A kind of fertilizer that utilizes the fermentation residue of plant fermented enzyme beverage to prepare, is made up of following raw material according to weight part: plant fermented fermented beverage fermented residue 88 parts, humic acid 45 parts, poultry manure 53 parts, urea 15 parts, phosphoric acid 12 parts of urea, 7.6 parts of potassium sulfate, 10 parts of superphosphate, 6.5 parts of trace element fertilizer, 3.9 parts of ascorbic acid, 2.1 parts of n-butyl triamine thiophosphate, 8.4 parts of deer marsh soil, 10.5 parts of saponins, 7.3 parts of pyrethrum, 5 parts of Shijunzi, 9.8 parts of purslane, 3.5 parts of Fructus Cnidii, 4 parts of JT composite strains, 5.5 parts of 5406 strains powder; described trace element fertilizer is made up of following raw material according to weight part: borax 12 6.8 parts of manganese sulfate, 13.4 parts of copper slag, 4.5 parts of cobalt fertilizer, 6.7 parts of ammonium molybdate, 8.6 parts of sodium selenite, 3.2 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com