Water-soluble povidone iodine powder preparation and preparation method thereof

A povidone-iodine and water-soluble technology, which is applied in the field of water-soluble povidone-iodine powder preparation and its preparation, can solve the problems affecting the effect, and achieve the effects of ensuring water solubility, avoiding residue and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Detect that the humidity of the purchased povidone K30 is 2.1%, weigh 100g, put it into a closed evaporator, add 3.9g of water, after high temperature gasification, the humidity of povidone K30 reaches 5%, weigh 25g of refined iodine and mix it Uniformly, put into the airtight evaporator, then steam heating 80 °, complexation for 40 hours, to room temperature, discharging to obtain povidone iodine, the available iodine weight percentage of the povidone iodine is greater than or equal to 14.0%, Detect its aldehyde < 50ppm, peroxide < 50ppm, sulfate ash < 0.02%.

Embodiment 2 9

[0019] Disperse 200 g of povidone-iodine obtained in Example 1 with 10 times the mass of water, then add 10 g of antioxidant and 10 g of pH stabilizer, then stir at room temperature for 20 minutes, add 12 g of potassium iodide, 15 g of potassium iodate, and 5 g of glycerin, Stir evenly to obtain a povidone-iodine aqueous solution; put the obtained aqueous solution into a lyophilizer to freeze-dry to obtain povidone-iodine powder, pass through a 200-mesh sieve to obtain a finished povidone powder preparation.

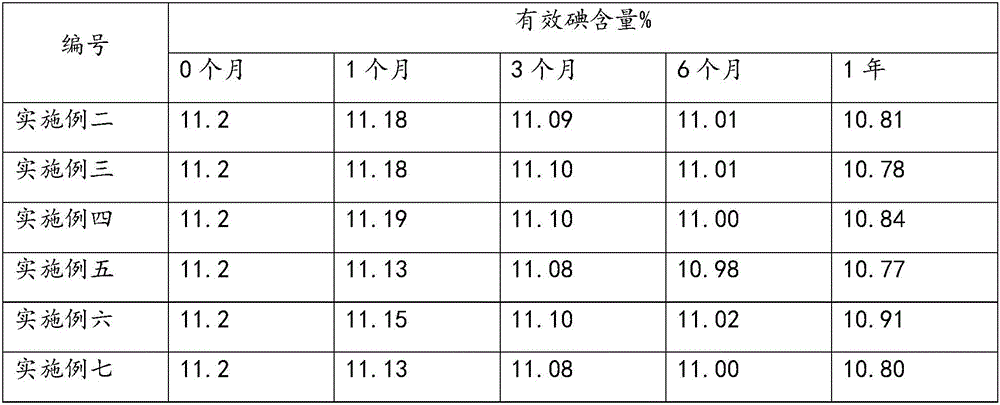

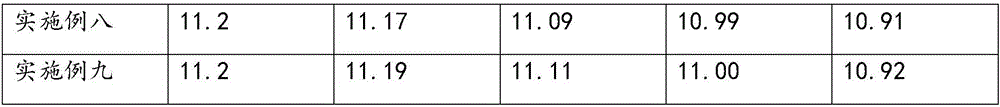

[0020] With reference to the weight of each component in Table 1, the operation steps are the same as above to obtain Embodiments three to ten,

[0021] The quality of each component in the embodiment two~nine of table 1

[0022]

Povidone iodine

potassium iodide

glycerin

Potassium dihydrogen phosphate

Embodiment two

200

12

15

5

10

10

Embodiment Three

220

15

20

7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com