Creep feed for piglets and preparation method thereof

A technology for teaching trough feed and suckling pigs, applied in the field of feed for feeding suckling pigs, can solve the problems of reduced production performance, decline in production performance, losses, etc., and achieve the effects of good palatability, large feed intake, and comprehensive and balanced nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

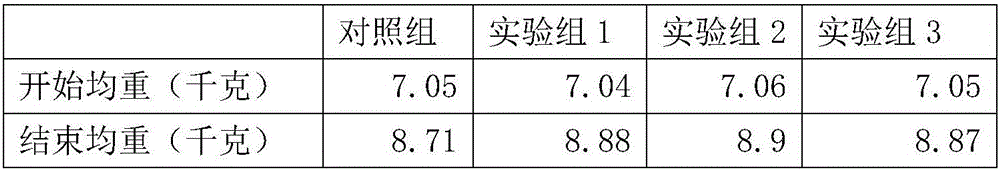

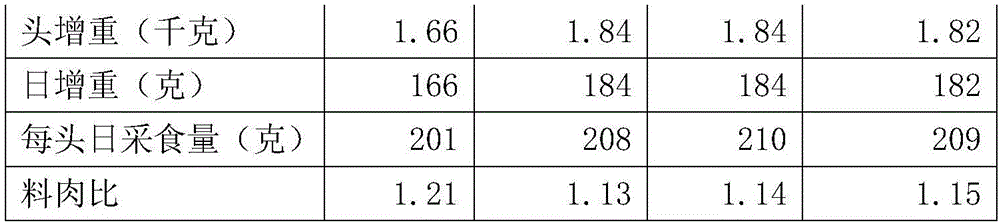

Examples

Embodiment 1

[0026] Example 1: A sucking pig creep feed, the components are calculated as follows in parts by weight: 200 parts of flour, 350 parts of broken rice, 100 parts of fine feeding powder, 46 parts of maltodextrin, 50 parts of enzymatically hydrolyzed soybean meal, yeast protein 30 parts, 80 parts of whey powder, 30 parts of whey protein concentrate, 20 parts of wheat hydrolyzed protein, 30 parts of glucose, 25 parts of soybean protein concentrate, 20 parts of fish meal, 10 parts of soybean oil, 0.2 parts of Bacillus subtilis, 0.2 parts of plant essential oil , 4 parts of sodium butyrate, 0.5 parts of suckling pig compound enzyme preparation, 4 parts of acidulant, and 0.1 part of water-soluble multidimensional.

[0027] Preparation:

[0028] In step a, the concentrated soybean protein, flour, broken rice, fish meal, and some soybean oil are subjected to high-temperature conditioning and granulation. The process of crushing the broken rice requires that 98% of the material fineness...

Embodiment 2

[0031] Example 2: A sucking pig creep feed, the components are calculated as follows in parts by weight: 150 parts of flour, 230 parts of broken rice, 60 parts of fine feeding powder, 60 parts of maltodextrin, 80 parts of enzymatic soybean meal, yeast protein 60 parts, 100 parts of whey powder, 50 parts of whey protein concentrate, 40 parts of wheat hydrolyzed protein, 40 parts of glucose, 50 parts of soybean protein concentrate, 40 parts of fish meal, 20 parts of soybean oil, 0.5 parts of Bacillus subtilis, 0.5 parts of plant essential oil , 3 parts of sodium butyrate, 0.8 part of suckling pig compound enzyme preparation, 15 parts of acidulant, and 0.2 part of water-soluble multidimensional.

[0032] Preparation:

[0033] In step a, the concentrated soybean protein, flour, broken rice, fish meal, and some soybean oil are subjected to high-temperature conditioning and granulation. The process of crushing the broken rice requires that 98% of the material fineness must pass thro...

Embodiment 3

[0036] Example 3: A sucking pig creep feed, the components are calculated as follows in parts by weight: 130 parts of flour, 300 parts of broken rice, 80 parts of fine feeding powder, 50 parts of maltodextrin, 60 parts of enzymatic soybean meal, yeast protein 45 parts, 130 parts of whey powder, 40 parts of whey protein concentrate, 30 parts of wheat hydrolyzed protein, 20 parts of glucose, 20 parts of soybean protein concentrate, 60 parts of fish meal, 16 parts of soybean oil, 1 part of Bacillus subtilis, 1 part of plant essential oil , 5 parts of sodium butyrate, 1 part of suckling pig compound enzyme preparation, 10 parts of acidulant, and 1 part of water-soluble multivitamin.

[0037] Preparation:

[0038] In step a, the concentrated soybean protein, flour, broken rice, fish meal, and some soybean oil are subjected to high-temperature conditioning and granulation. The process of crushing the broken rice requires that 98% of the material fineness must pass through a 40-mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com