High-strength lining

A technology with high-strength pads, applied in the field of high-strength pads, it can solve the problems of cumbersome processing and assembly procedures, reduced friction area, deformation of the plate neck, etc., so as to overcome the bending deformation or fracture of the plate neck and prevent contact The effect of reducing the area and increasing rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and the best embodiments.

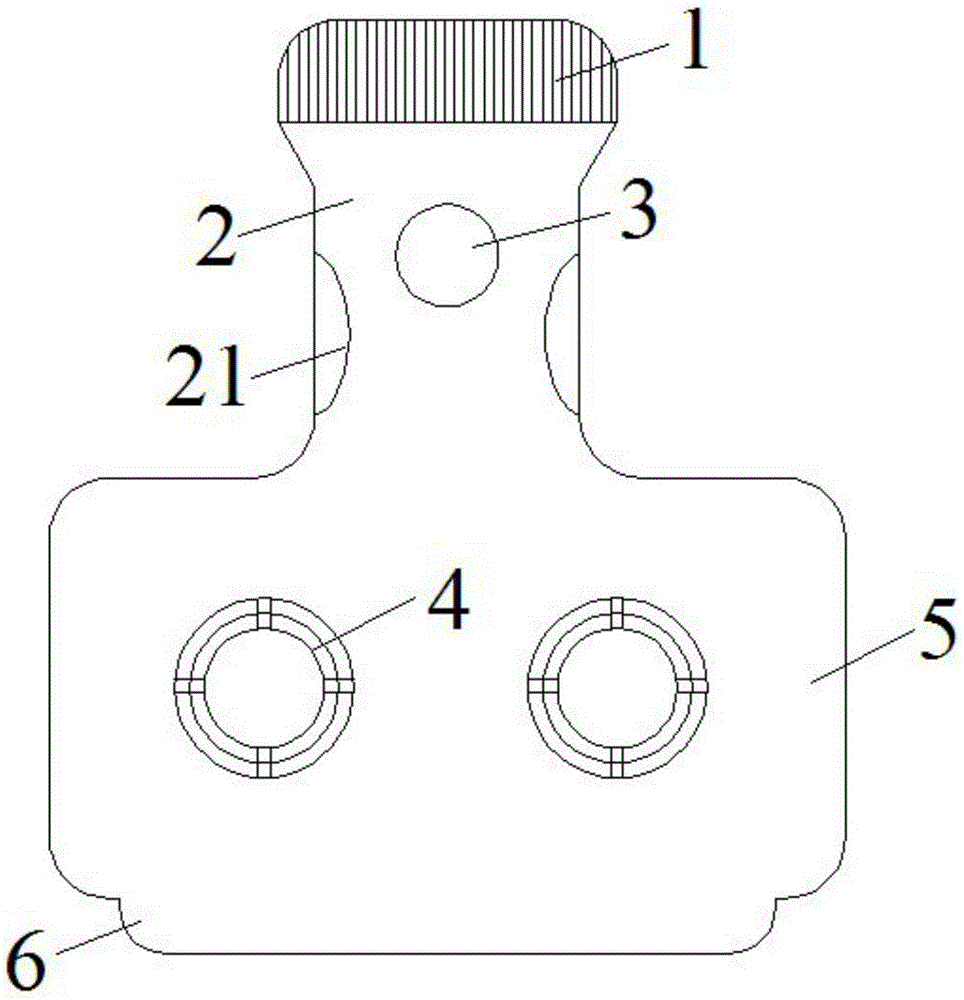

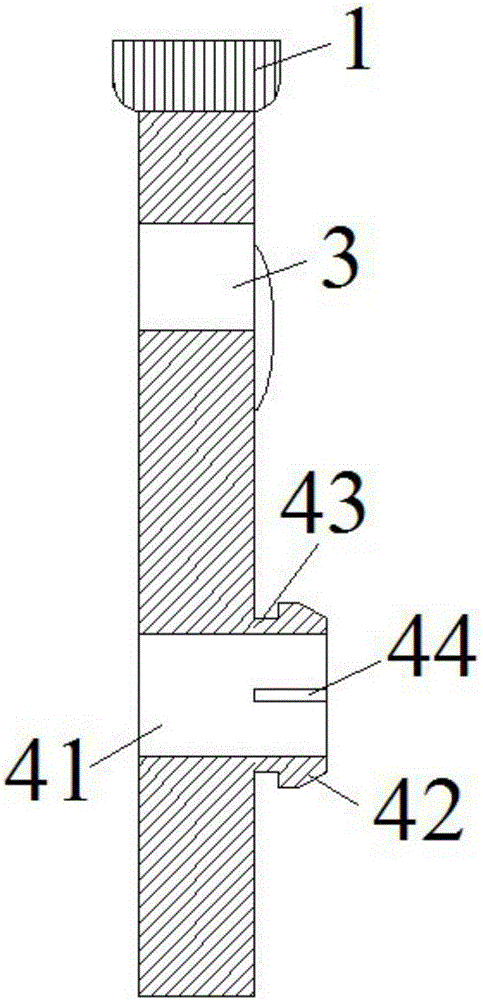

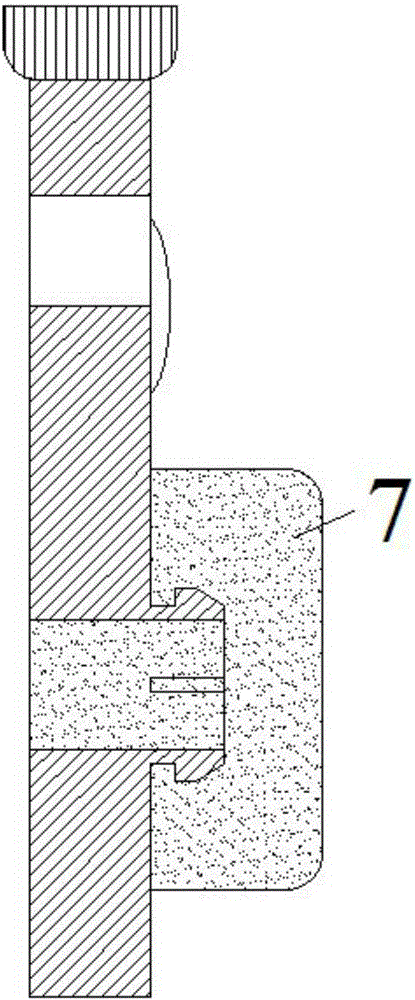

[0021] A high-strength pad of the present invention includes a fixed plate and a friction block 7 that are fixedly connected. The fixed plate includes a fixed plate body 5, a plate neck 2 extending from one end of the fixed plate body, and a fixed plate protruding perpendicular to the fixed plate body. The column 4, the fixing hole 3 on the plate neck and the positioning part 6 at the other end of the fixing plate body. The fixing column is provided with a coaxial embedding hole 41 which penetrates the fixing plate body, and the column end 42 of the fixing column is provided with a convex The plane of the boss and the fixed plate body forms an annular groove 43 on the fixed column, and the fixed column is also provided with a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com