Device for selective etching of quartz wafers

A quartz wafer, selective technology, applied in the direction of crystal growth, impedance network, electrical components, etc., can solve the problems of complex process and high processing cost, and achieve the effect of simple operation, short processing process and deep corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

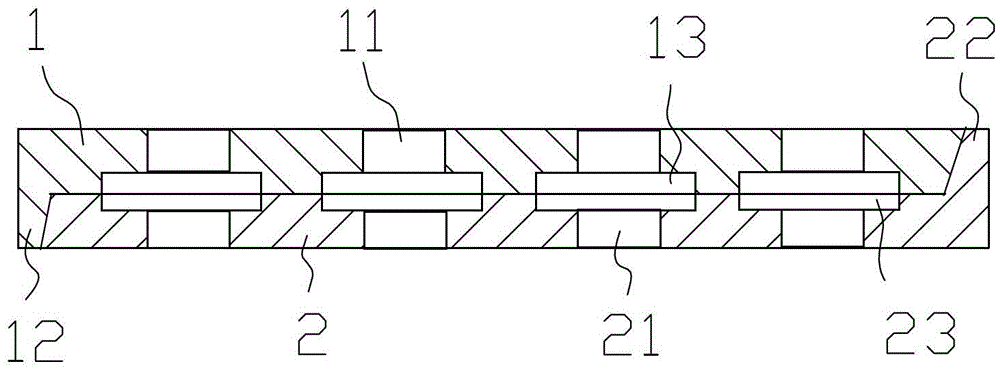

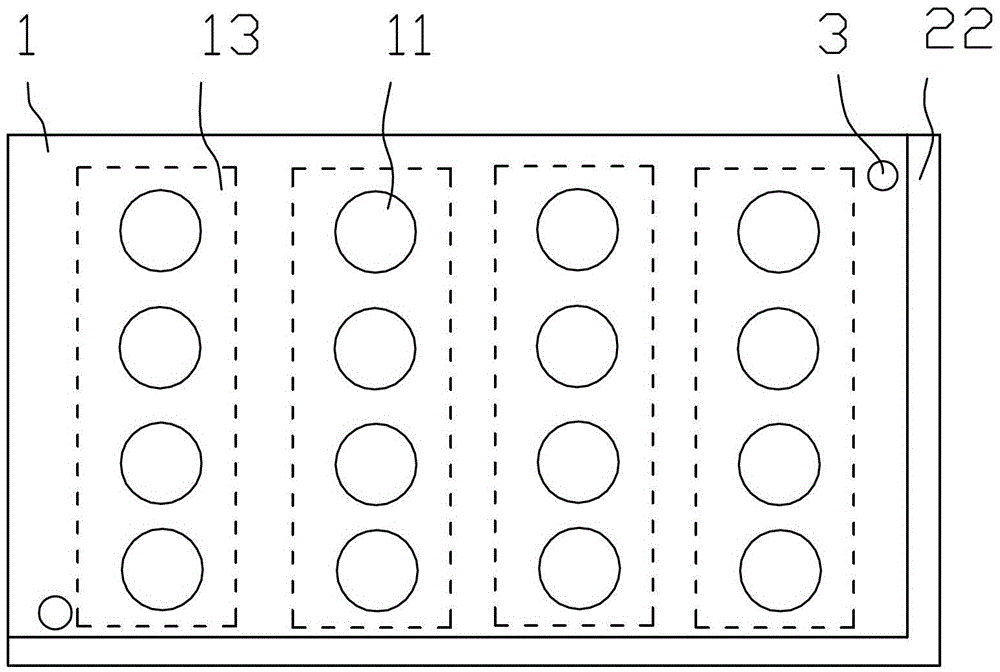

[0013] Depend on figure 1 with figure 2 As shown, the device for selectively corroding quartz wafers of the present invention includes upper and lower splints 1, 2 made of corrosion-resistant materials. The area has a plane area that cooperates with each other, and the plane area on the lower end surface of the upper clamping plate 1 and the upper end surface of the lower clamping plate 2 respectively has several upper and lower mold cavities 13, 23 that are matched with the crystal square and whose height is half the thickness of the crystal square. . In this example, four upper and lower mold cavities 13, 23 are respectively arranged on the upper and lower splints 1, 2, and each mold cavity can place a crystal square.

[0014] The upper and lower splints 1, 2 are respectively opened with four corrosion holes 11, 21 communicating with the areas to be etched at the upper and lower ends of the crystal square. The processed crystal square in this example is a rectangular she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com