Method for preparing metal aluminum from bauxite through microwave chlorination

A technology for bauxite and metal aluminum, which is applied in the field of preparing metal aluminum by microwave chlorination of bauxite, can solve the problems of increased consumption of limestone and coke, reduced comprehensive utilization efficiency of ore, reduced N/S of dissolved red mud, etc. Uniform, high economic and social benefits, the degree of automation, environmental protection and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

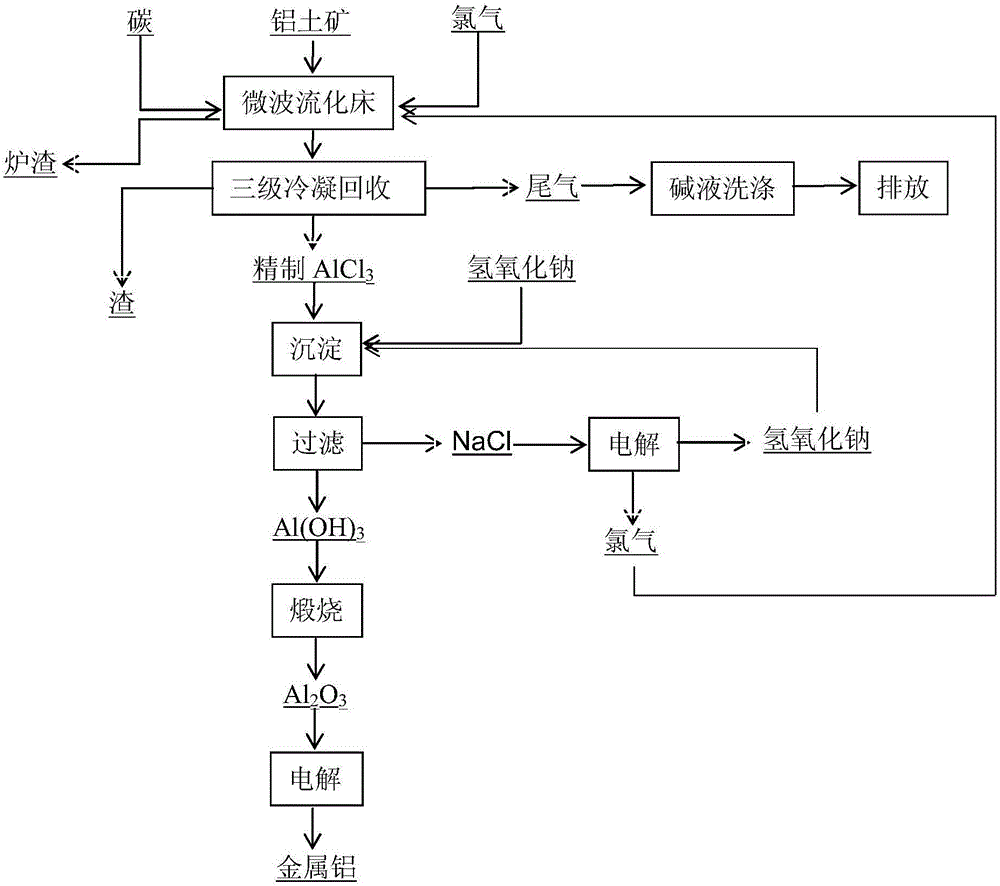

[0049] A method for preparing aluminum metal by microwave chlorination of bauxite comprises the following steps:

[0050] Step 1, chlorination and decomposition of bauxite by microwave heating:

[0051] The low-grade bauxite is mixed with carbon and crushed to -250 μm, then chlorine gas is introduced, the pressure is normal pressure, and the microwave frequency is 2.5 GHz microwave fluidized bed is used to heat for 10 minutes, reaching 800 ° C, constant temperature for 30 minutes, and the low-grade bauxite Bauxite is fully decomposed to obtain a variety of chlorinated mixed gases containing aluminum chloride; among them, in low-grade bauxite, the mass ratio of alumina content to silicon oxide content is equal to 7, according to the mass ratio, low-grade bauxite : carbon = 1:2, low-grade bauxite: chlorine = 1:4;

[0052] Step 2, separation and purification, precipitation of aluminum chloride:

[0053] (1) The impurity removal and refining process is to use a variety of chlori...

Embodiment 2

[0063] A method for preparing aluminum metal by microwave chlorination of bauxite comprises the following steps:

[0064] Step 1, chlorination and decomposition of bauxite by microwave heating:

[0065] The nepheline is mixed with carbon and crushed to -250 μm, then chlorine gas is introduced, the pressure is normal pressure, and the microwave frequency is 2.3 GHz microwave fluidized bed is used to heat for 30 minutes, reaching 900 ° C, and the temperature is maintained for 15 minutes to fully decompose the nepheline. Obtain the multiple chlorinated mixed gases containing aluminum chloride; Wherein, in nepheline, the mass ratio of aluminum oxide content and silicon oxide content is equal to 6, by mass ratio, nepheline: carbon=1: 1.5, nepheline: chlorine = 1:3;

[0066] Step 2, separation and purification, precipitation of aluminum chloride:

[0067] (1) The impurity removal and refining process is to use a variety of chlorinated mixed gases containing aluminum chloride to re...

Embodiment 3

[0077] A method for preparing aluminum metal by microwave chlorination of bauxite comprises the following steps:

[0078] Step 1, chlorination and decomposition of bauxite by microwave heating:

[0079] The feldspar is mixed with carbon and crushed to -250 μm, then chlorine gas is introduced, the pressure is normal pressure, and the microwave frequency is 2.4 GHz microwave fluidized bed is used to heat for 10 minutes, reaching 700 ° C, and the temperature is maintained for 20 minutes to fully decompose the feldspar. Obtain the multiple chlorinated mixed gases containing aluminum chloride; Wherein, in feldspar, the mass ratio of aluminum oxide content and silicon oxide content is equal to 7, by mass ratio, feldspar: carbon=1: 3, feldspar: chlorine= 1:5;

[0080] Step 2, separation and purification, precipitation of aluminum chloride:

[0081] (1) The impurity removal and refining process is to use a variety of chlorinated mixed gases containing aluminum chloride to remove imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com