A process for extracting scandium from gas ash

A technology of gas ash and process, which is applied in the field of extracting scandium from gas ash, can solve the problems that are not conducive to recycling, achieve strong economic value, simple processing method and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

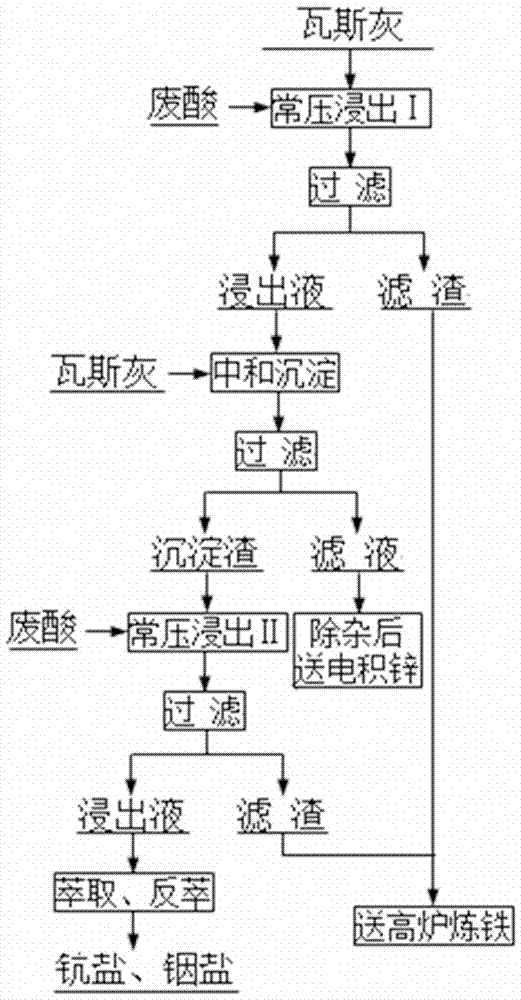

Method used

Image

Examples

Embodiment 1

[0032] Atmospheric pressure leaching Ⅰ acid concentration: sulfuric acid 100g / L, leaching time 30min, leaching at room temperature, liquid-solid ratio 1.5:1, leaching rate 31.50%; 10min, the reduction temperature is normal temperature, the reduction rate is 30.52%; the leachate is precipitated with gas mud (ash), the dosage is 10g / L, the precipitation temperature is normal temperature, the precipitation time is 30min, the scandium content can be enriched to 16.3 times, and the precipitation rate is 86.19%; the obtained precipitated residue Sulfuric acid leaching, leaching at room temperature, leaching time 30min, leaching liquid-solid ratio 1.5:1, acid concentration 100g / L, leaching rate 91.50%; leaching liquid is extracted at room temperature with P204, diluent is kerosene, extraction agent concentration is 5%, extraction grade The number is level 1, the extraction time is 1min, the extraction ratio O / A is 1:3, and the extraction rate is 98.26%. The O / A ratio is 3:1, the stri...

Embodiment 2

[0034] Atmospheric pressure leaching Ⅰ acid concentration: hydrochloric acid 200g / L, leaching time 180min, leaching temperature 60°C, liquid-solid ratio 3:1, leaching rate: 65.26%; the obtained leaching solution is reduced with zinc sulfide concentrate, and the amount of reducing agent is 3g / L , the reduction time is 120min, the reduction temperature is 60°C, the reduction rate is 48.37%; the leachate is precipitated with gas mud (ash), the dosage is 30g / L, the precipitation is at 60°C, the precipitation time is 50min, the scandium content can be enriched to 13.4 times, and the precipitation rate is 53.46% The obtained precipitated residue was leached with hydrochloric acid, the leaching temperature was 70°C, the leaching time was 180min, the leaching liquid-solid ratio was 3:1, the acid concentration was 200g / L, and the leaching rate was 87.36%; The extraction ratio is 20%, the extraction stage is 3, the extraction time is 3min, the extraction ratio O / A is 1:3, and the extract...

Embodiment 3

[0036] Atmospheric pressure leaching Ⅰ acid concentration: sulfuric acid 300g / L, leaching time 300min, leaching temperature 90°C, liquid-solid ratio 8:1, leaching rate: 54.69%; the obtained leaching solution is reduced with zinc sulfide concentrate, and the amount of reducing agent is 20g / L , reduction time 240min, reduction at 90°C, reduction rate 40.81%; leachate was precipitated with gas mud (ash), dosage 100g / L, precipitation at 90°C, precipitation time 120min, scandium content can be enriched to 15.8 times, precipitation rate 83.25% The obtained precipitated residue is leached with hydrochloric acid, the leaching temperature is 90°C, the leaching time is 300min, the leaching liquid-solid ratio is 8:1, the acid concentration is 300g / L, and the leaching rate is 93.92%; is 40%, the extraction stage is 7, the extraction time is 7min, the extraction ratio O / A is 1:8, and the extraction rate is 93.17%; the scandium-loaded organic phase is back-extracted with hydrochloric acid at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com