Polyimide-based adhesive, film adhesive, adhesive layer, adhesive sheet, copper-clad laminate, wiring board and its manufacturing method

A technology of polyimide and adhesive materials, which is applied in the fields of adhesives, chemical instruments and methods, and printed circuit manufacturing, and can solve problems such as insufficient dielectric properties and low heat-resistant adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

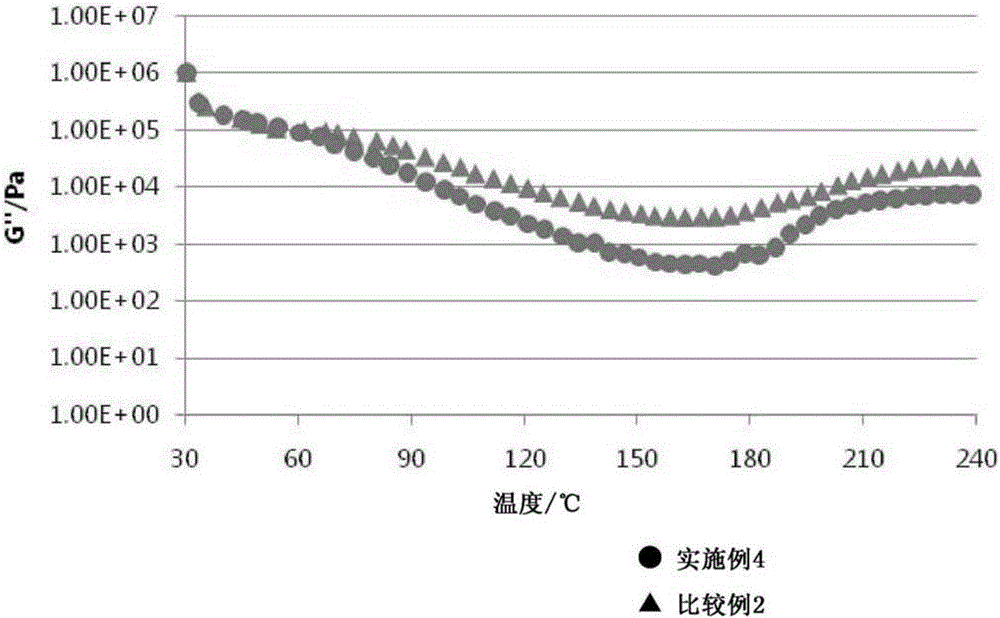

[0116] Hereinafter, although an Example and a comparative example demonstrate this invention concretely, the scope of this invention is not limited to these examples. In addition, in each example, unless otherwise stated, a part and % are based on weight. It should be noted that the number average molecular weight is a value obtained using a commercially available measuring device ("HLC-8220GPC", manufactured by Tosoh Corporation), and the softening point is a value obtained using a commercially available measuring device ("ARES-2KSTD-FCO -STD", manufactured by Rheometric Scientific Company).

[0117]

manufacture example 1

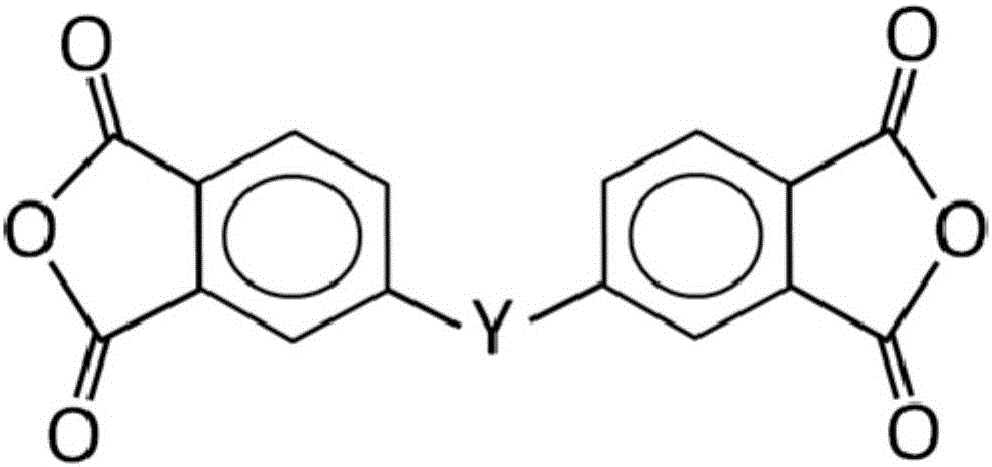

[0119] 3,3',4,4'-benzophenone tetracarboxylic dianhydride (trade name "BTDA-PF", Ebonick Japan Co., Ltd. Manufacture) 225.00g, cyclohexanone 1046.25g and methylcyclohexane 209.25g, heated to 60°C. Next, 345.93 g of dimer diamine (trade name "PRIAMINE 1075", manufactured by Croda Japan Co., Ltd.) was added, and an imidization reaction was carried out at 130° C. for 12 hours to obtain an acid anhydride group-terminated polyimide ( A1-1) (hereinafter also referred to as (A1-1) component) solution (31.0% of non-volatile content). The molar ratio of the acid component / amine component of this (A1-1) component was 1.08, the number average molecular weight was 8500, and the softening point was 70 degreeC.

manufacture example 2

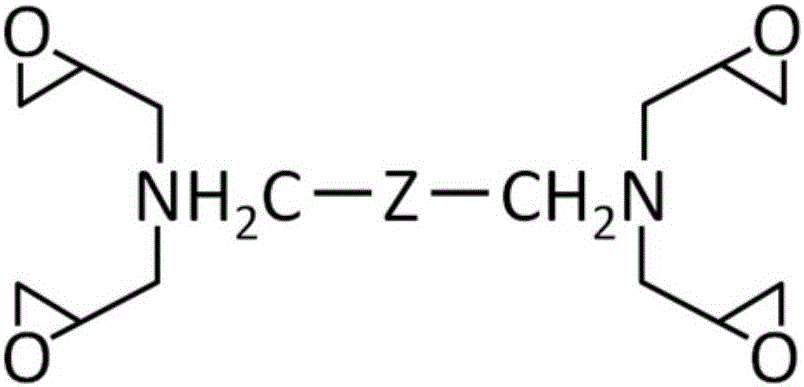

[0121] 755.63 g of the solution of the above-mentioned (A1-1) component was injected|thrown-in to the reaction container similar to manufacture example 1, and the solvent was distilled off under reduced pressure until the non-volatile matter became 34.4%. Next, 2.76 g of octylamine (trade name "Lipomin 8D", manufactured by Lion Specialty Chemicals Co., Ltd.) was further added as the component (A2), and reacted at 140° C. for 16 hours to obtain a blocked polyimide (1 -1) (hereinafter also referred to as (1-1) component) solution (35.9% of non-volatile content). The (1-1) component had an acid anhydride terminal group / octylamine molar ratio of 1.0, a number average molecular weight of 10,000, and a softening point of 70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com