Manufacturing method of cyclic utilization type pressure-sensitive adhesive tape

A type of pressure-sensitive adhesive tape and manufacturing method technology, applied in the direction of pressure-sensitive film/sheet, adhesive, film/sheet-shaped adhesive, etc., can solve problems such as difficult handling, residual glue, and non-recyclable protective film, etc. Achieve superior moisture and water resistance, reduce pollution, and facilitate reuse and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

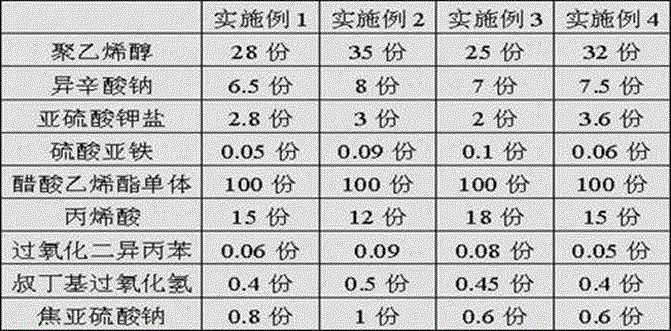

[0030] Embodiment 1~4: A kind of manufacturing method of recycling type pressure-sensitive adhesive tape, comprises polypropylene film, pressure-sensitive modified EVA adhesive layer and release material layer, and described pressure-sensitive modified EVA adhesive layer is positioned at Between the polypropylene film and the release material layer;

[0031] The pressure-sensitive modified EVA adhesive layer 2 is composed of the following components:

[0032] Table 1

[0033]

[0034] The modified EVA aqueous solution is further obtained through the following steps:

[0035] Step 1, dissolving 20-40 parts of polyvinyl alcohol, 6-8 parts of sodium isooctanoate, 2-4 parts of potassium sulfite and 0.05-0.1 part of ferrous sulfate in ionized water to form an aqueous mixture;

[0036] Step 2, put the aqueous mixture of step 1 into the autoclave, and then feed ethylene to replace the air in the autoclave;

[0037] Step 3: Warm up the reaction kettle jacket water to the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com