Method for removing sulfate and Zn(II) wastewater by virtue of synergism of spongy iron and microorganisms

A sponge iron and sulfate technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low unit microbial content, poor settling performance, strain loss, etc. To achieve the effect of simple equipment, convenient operation and strong electrochemical enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

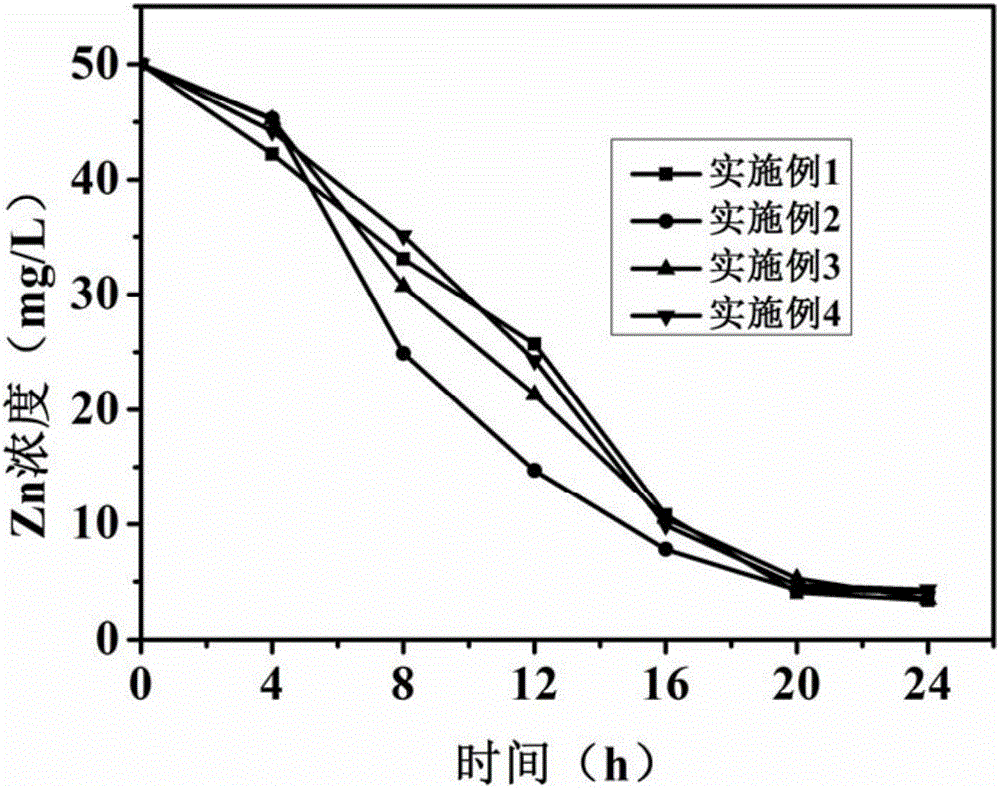

Embodiment 1

[0038] A method for the collaborative removal of sulfate and Zn(II) wastewater by sponge iron and microorganisms comprises the following steps:

[0039] (1) Preparation of sponge iron

[0040] Under the conditions of carbon content (mass ratio of simple carbon powder to iron slime) 2:3, reaction temperature 1200°C, and reaction time 30 minutes, iron slime was used as raw material to calcinate to prepare conventional sponge iron solid. Activate with dilute hydrochloric acid to prepare a sponge iron solution with a concentration of 0.3 g / L, which is designated as reaction solution A.

[0041] (2) Preparation of sulfate reducing bacteria SRB

[0042] Select 2 rings from a sulfate-reducing bacterium—Desulfovibrio (Desulfovibrio; Desulfovibrio subsp. Transfer to 40ml Desulfovibrio nutrient medium, culture in the dark at 35°C for 5 days, use Desulfovibrio proliferation medium with 5% inoculum to carry out expanded culture for 2 days, and centrifuge at 3000r / min for 20min to obtain...

Embodiment 2

[0054] A method for the collaborative removal of sulfate and Zn(II) wastewater by sponge iron and microorganisms comprises the following steps:

[0055] (1) Preparation of sponge iron

[0056] Under the conditions of carbon content (mass ratio of simple carbon powder to iron slime) 2:3, reaction temperature 1200°C, and reaction time 30 minutes, iron slime was used as raw material to calcinate to prepare conventional sponge iron solid. Activate with dilute hydrochloric acid to prepare a sponge iron solution with a concentration of 0.5 g / L, which is designated as reaction solution A.

[0057] (2) Preparation of sulfate reducing bacteria SRB

[0058] Select 2 rings from a kind of sulfate-reducing bacterium—Desulfovibrio (same as Example 1) purchased by China Common Microorganism Culture Collection and Management Center, transfer it to 30ml nutrient solution, and cultivate it in the dark at 35°C for 4d, and then 5% of the inoculum was expanded with proliferation medium for 3 day...

Embodiment 3

[0070] A method for the collaborative removal of sulfate and Zn(II) wastewater by sponge iron and microorganisms comprises the following steps:

[0071] (1) Preparation of sponge iron

[0072] Under the conditions of carbon content (mass ratio of simple carbon powder to iron slime) 2:3, reaction temperature 1200°C, and reaction time 30 minutes, iron slime was used as raw material to calcinate to prepare conventional sponge iron solid. Activate with dilute hydrochloric acid to prepare a sponge iron solution with a concentration of 0.1 g / L, which is designated as reaction solution A.

[0073] (2) Preparation of sulfate reducing bacteria SRB

[0074] Select 2 rings from a kind of sulfate-reducing bacterium—Desulfovibrio (same as Example 1) purchased by China Common Microorganism Culture Collection and Management Center, transfer it to 30ml nutrient solution, and cultivate it in the dark at 35°C for 5d, 5% of the inoculum was expanded with proliferation medium for 2 days, and ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com