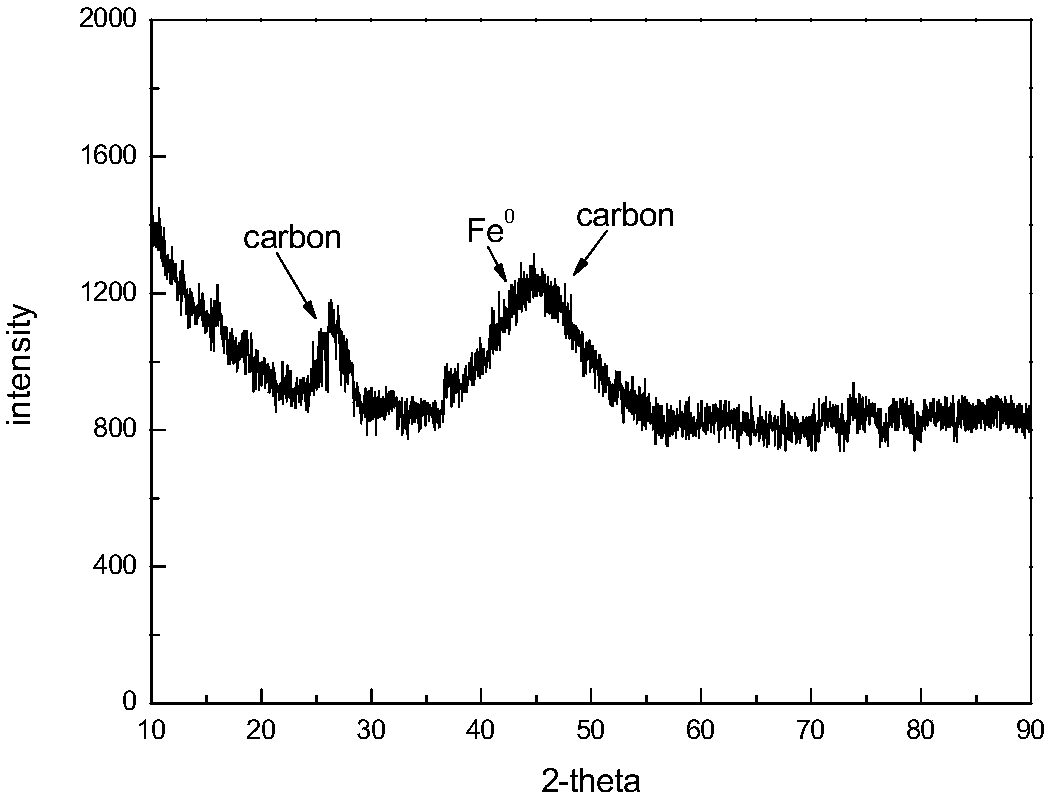

Preparation method of multi-walled carbon nanotube/nanoscale bimetallic zero-valent iron composite material

A technology of multi-wall carbon nanotubes and composite materials is applied in the field of preparation of multi-wall carbon nanotubes/nano-scale bimetallic zero-valent iron composite materials, and can solve the problems of uneven particle distribution, easy agglomeration, and difficulty in recycling. Achieve uniform particle size distribution, rapid response and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Under the action of ultrasonic (40KHz, 150W) and continuous stirring under nitrogen, the temperature of the water bath is 30°C, and the concentration of 200mL is 0.50mol L -1 NaBH 4 The aqueous solution was added dropwise within 10 minutes to a container with an equal volume of 0.25mol·L -1 FeSO 4 ·7H 2 In the 500mL three-neck flask of O aqueous solution, continue to react for 10min after the dropwise addition, and then add 26.8mL of 0.005mol·L -1 K 2 PdCl 6 The aqueous solution was reacted for 75 minutes (the color of the solution changed from reddish brown to light green), and nanoscale Pd / Fe particles were generated in the reaction system. 0.2g of MWCNTs with a diameter of 10-20nm was added to the nanoscale Pd / Fe system, and continued The reaction was stirred for 120 min, and the stabilized MWCNTs / nano-scale Pd / Fe composite particles were selected by magnetic separation, washed with anaerobic deionized water (50mL × 3), and then washed with absolute ethanol (50m...

Embodiment 2

[0046] Under the action of ultrasonic (40KHz, 150W) and continuous stirring under nitrogen, the temperature of the water bath is 30°C, and the concentration of 200mL is 0.50mol L -1 NaBH 4 The aqueous solution was added dropwise within 10 minutes to a container with an equal volume of 0.25mol·L -1 FeSO 4 ·7H 2 In the 500mL three-necked flask of O aqueous solution, continue to react for 10min after the dropwise addition, and then add 44.67mL of 0.003mol·L -1 K 2 PdCl 6 The aqueous solution was reacted for 75 minutes (the color of the solution changed from reddish brown to light green), and nanoscale Pd / Fe particles were generated in the reaction system. 0.2g of MWCNTs with a diameter of 10-20nm was added to the nanoscale Pd / Fe system, and continued The reaction was stirred for 120 min, and the stabilized MWCNTs / nano-scale Pd / Fe composite particles were selected by magnetic separation, washed with anaerobic deionized water (50mL × 3), and then washed with absolute ethanol (...

Embodiment 3

[0051] Under the action of ultrasonic (40KHz, 150W) and continuous stirring under nitrogen, the temperature of the water bath is 30°C, and the concentration of 200mL is 0.50mol L -1 NaBH 4 The aqueous solution was added dropwise within 10 minutes to a container with an equal volume of 0.25mol·L -1 FeSO 4 ·7H 2 In the 500mL three-neck flask of O aqueous solution, continue to react for 10min after the dropwise addition, and then add 37.5mL of 0.005mol·L -1 K 2 PdCl 6 The aqueous solution was reacted for 90 minutes (the color of the solution changed from reddish brown to light green), and nanoscale Pd / Fe particles were generated in the reaction system. 0.2g of MWCNTs with a diameter of 10-20nm was added to the nanoscale Pd / Fe system, and continued The reaction was stirred for 120 min, and the stabilized MWCNTs / nano-scale Pd / Fe composite particles were selected by magnetic separation, washed with anaerobic deionized water (50mL × 3), and then washed with absolute ethanol (50m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com