An integral casting bucket

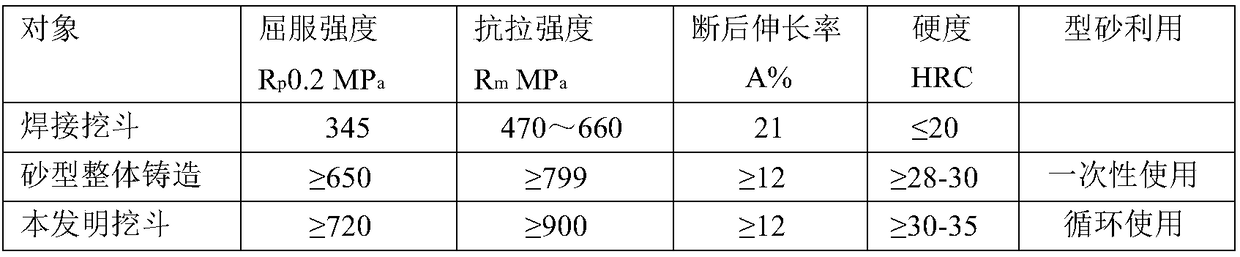

A technology of integral casting and steel casting, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of workpiece cracking, quenching deformation, insufficient cleaning ability, etc., to increase friction, improve wear resistance, improve The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

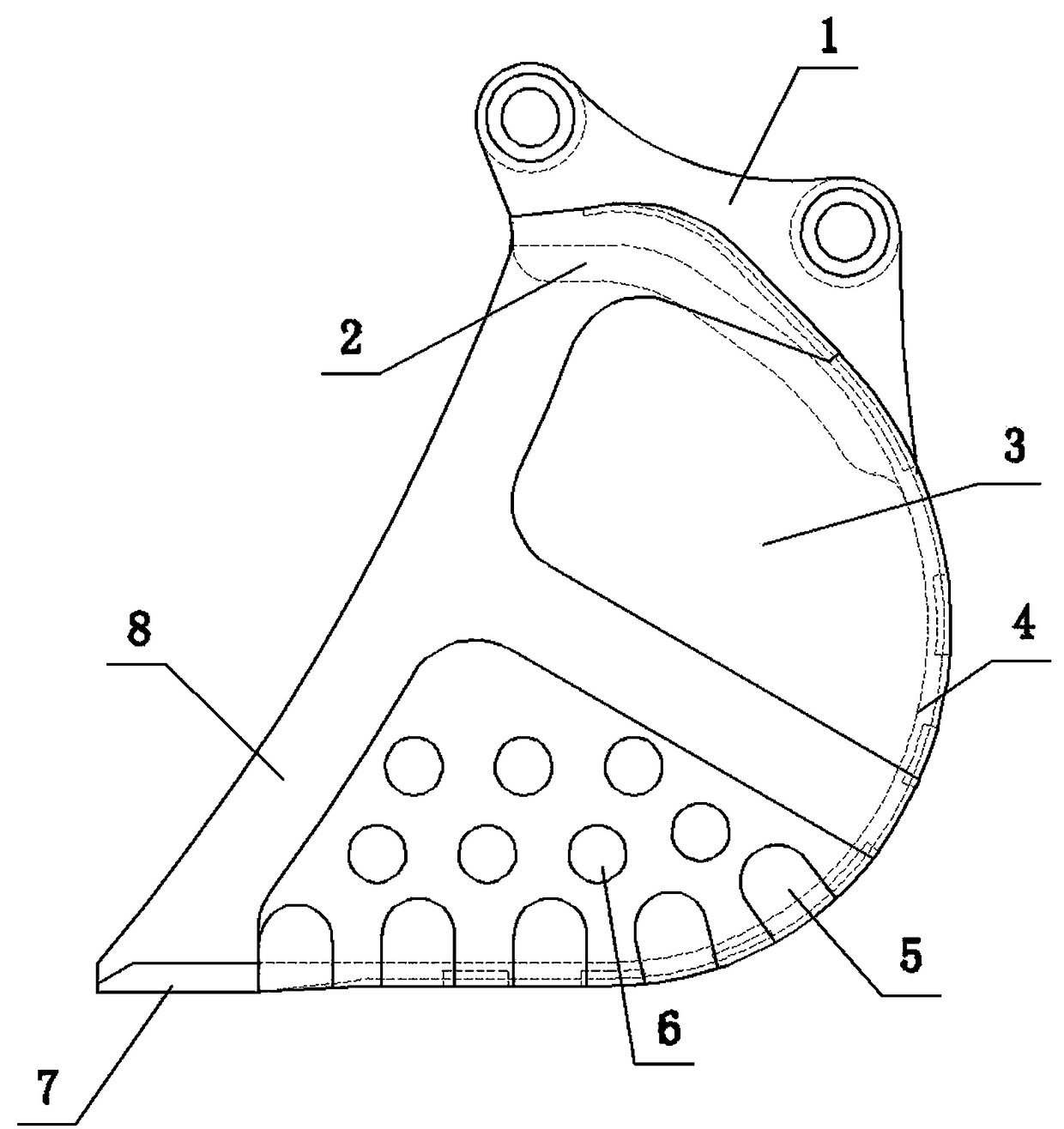

[0081] An integrally cast bucket includes a lifting lug 1, a top plate, two side plates 3, and a bottom plate 4 connected to the two side plates 3. The lifting lug 1, the top plate, the two side plates 3 and the bottom plate 4 form an integral structure.

[0082] The side plate 3 is provided with a side tooth plate 8 , and the connection between the lifting lug 1 and the top plate is provided with a lifting lug reinforcing rib 2 .

[0083] A plurality of wear-resistant blocks 5 and wear-resistant balls 6 are provided in the area of the side plate 3 close to the front 7 of the bucket, and the wear-resistant blocks 5 are close to the junction of the side plate 3 and the bottom plate 4 .

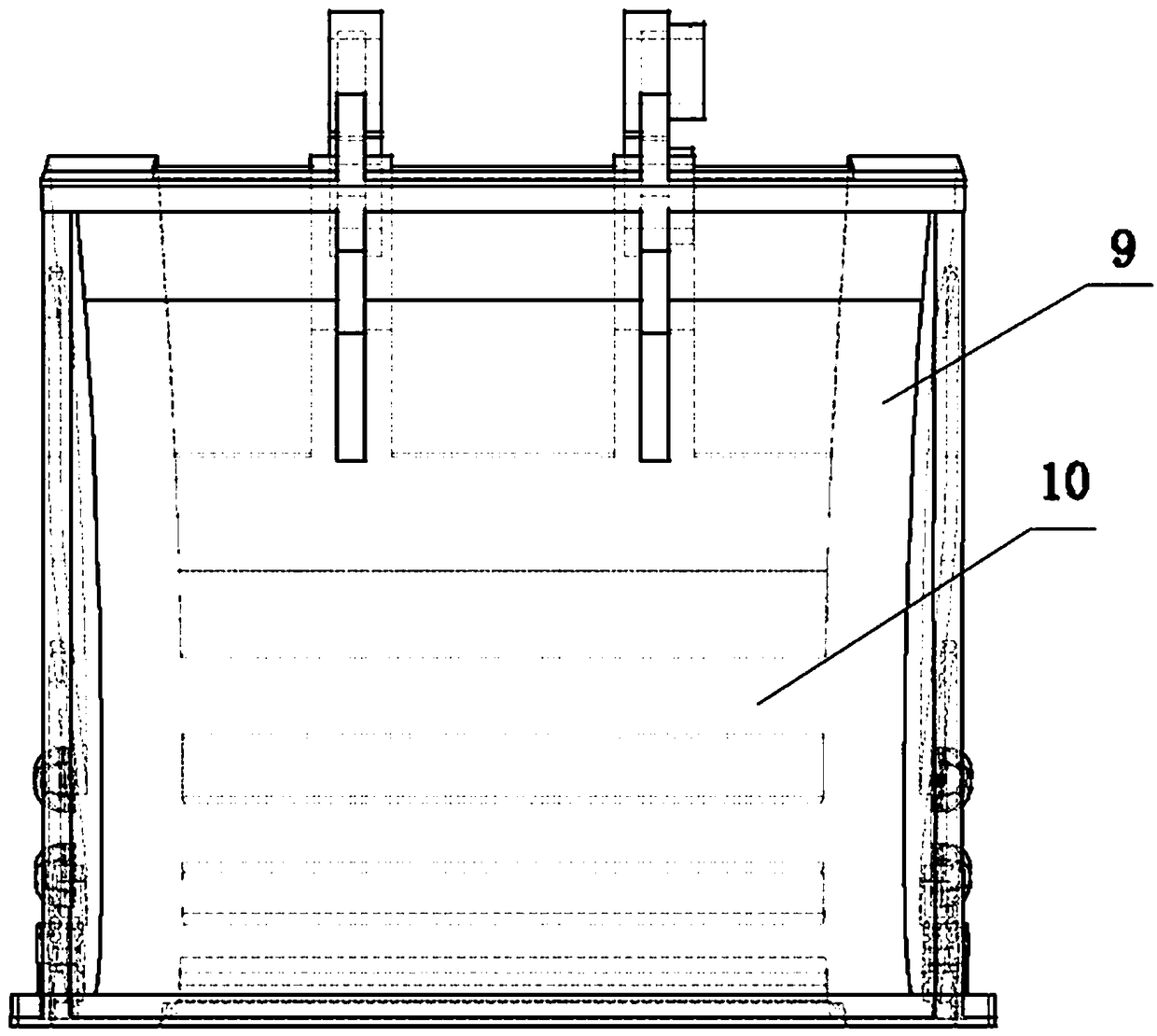

[0084] The bottom plate 4 is provided with two longitudinal ribs 9 near the side plates 3 , and a plurality of transverse ribs 10 are provided in the middle of the bottom plate 4 .

[0085] The overall structure of the integral casting bucket includes lifting lug 1, lug reinforcing rib 2, top...

Embodiment 2

[0087] A kind of cast steel for casting described bucket, the composition of described cast steel is as follows:

[0088] C: 0.1% to 0.6%; Si: 0.2% to 0.6%; Mn: 0.5% to 1.8%; Cr: 0.5% to 1.6%; Ni: 0.2% to 0.75%; Mo: 0.1% to 0.6%; P≤ 0.035%, S≤0.035%, and the balance is iron.

Embodiment 3

[0090] A kind of cast steel for casting described bucket, the composition of described cast steel is as follows:

[0091] C: 0.3%; Si: 0.3%; Mn: 1.8%; Cr: 1.6%; Ni: 0.55%; Mo: 0.3%; P: 0.025%, S: 0.015%, and the balance is iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com