Graphene-wrapping zinc oxide three-dimensional composite material catalyst and preparation method and application thereof

A technology of graphene wrapping and composite materials, which is applied in the preparation of catalyst materials and the field of electrochemical sensors, to achieve the effect of increasing the active area, good stability, and easy and controllable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of graphene oxide.

[0034] Mix 1g of graphite powder with commercially available concentrated nitric acid (3mL) and concentrated sulfuric acid (30mL) in an ice-water bath, add 2-5g of potassium permanganate while stirring, heat up to 45°C for 1 hour, then heat up to 90°C for 1 hour hour, cooled to room temperature, and stood overnight; the resulting precipitate was washed three times with distilled water and once with ethanol, and then dried at 40°C for 24 hours to obtain a graphene oxide solid.

Embodiment 2

[0036] Preparation of graphene-coated zinc oxide three-dimensional composite catalyst (3DRGO-ZnO).

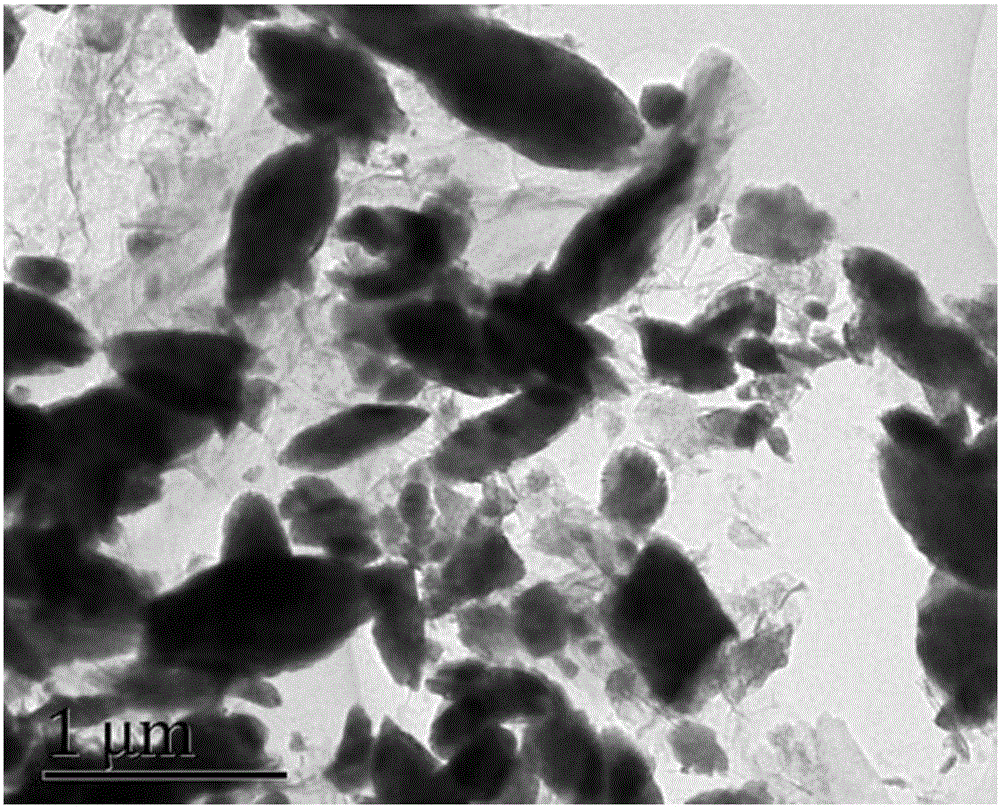

[0037] Weigh 30 mg of graphene oxide prepared in Example 1 and disperse evenly in 60 mL of distilled water by ultrasonic for 30 minutes, transfer it to a 100 mL reaction kettle, and immerse the zinc foil in the above-mentioned graphene oxide aqueous solution, place in an oven Insulate at 100°C for 1 hour to reduce graphene oxide; after cooling to room temperature, transfer the zinc sheet to a clean beaker with tweezers, add 20 mL of distilled water for ultrasonic oscillation, centrifuge the obtained solution, wash the solid with distilled water for 3 times, and wash with ethanol for 1 time, then place in Dry in 40C ° oven for 24 hours, as shown in TEM picture ( figure 1 ), the obtained solid is graphene-coated zinc oxide three-dimensional composite catalyst 3DRGO-ZnO.

[0038] As a comparison, a graphene catalyst material (RGO) was prepared by hydrothermally reducing graphene...

Embodiment 3

[0040] Preparation of electrochemical sensor and quantitative determination of chloramphenicol.

[0041] Weigh 2 mg of the graphene-coated zinc oxide three-dimensional composite catalyst 3DRGO-ZnO prepared in Example 2 and disperse evenly in 1 mL of absolute ethanol by ultrasonication for 5 minutes to prepare a catalyst dispersion with a concentration of 2.0 mg / mL. Transfer 10 μL of the dispersion to the active surface of a clean glassy carbon electrode with a liquid gun and dry it with an infrared lamp to obtain an electrochemical sensor. Using a saturated calomel electrode as a reference electrode, a platinum wire as an auxiliary electrode, and a phosphate buffer solution (pH=7.4) as a measurement medium, differential pulse voltammetry was used to measure the Electrochemical scanning of chloramphenicol standard solution shows that graphene-coated zinc oxide three-dimensional composite catalyst 3DRGO-ZnO has the strongest current response intensity compared with graphene mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com