Preparation method of enramycin premixing agent

A technology of enramycin and premix, which is applied in the field of preparation of enramycin premix, which can solve problems affecting quality, sales and use, low yield of enramycin, product instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

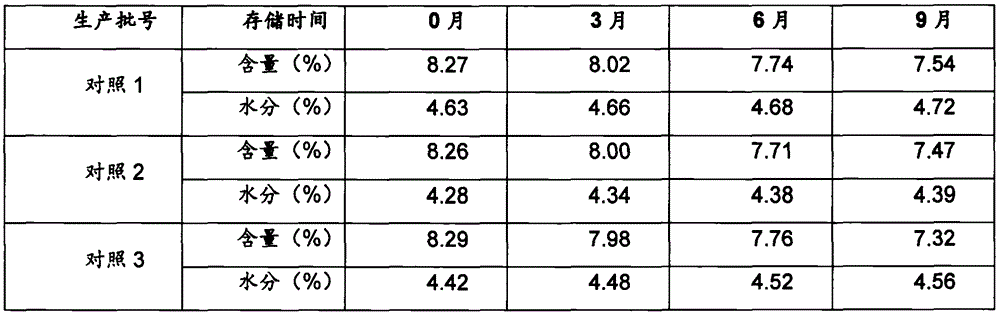

[0016] Control group: traditional process: the test procedure is (1) carry out plate and frame filtration with enramycin fermented liquid, the pressure of plate and frame filtration is 0.4MPa, the pressure filtration time is 3h, and air blowing time is 1.0h; (2) obtained The mycelium of enramycin is obtained after the filter cake is flash-dried, the inlet air temperature is 90-150°C, and the material temperature is 60-90°C.

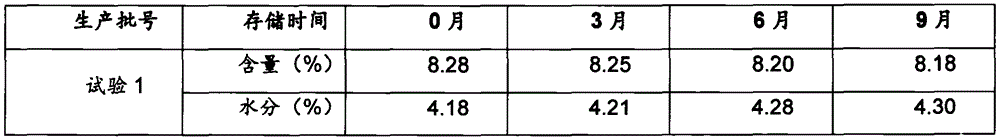

[0017] Experimental group: using the present invention: a preparation method of enramycin premix, which is characterized in that it comprises the following steps: (1) carrying out plate and frame filtration of enramycin fermented liquid; (2) flash drying of the gained filter cake Finally, obtain the mycelia of enramycin: (3) fully stir after the mycelium and auxiliary material are diluted in proportion: (4) dry after the enramycin dilution is stirred evenly, obtain enramycin pre- mixture;

[0018] The weight ratio of described step (3) enramycin mycelium...

Embodiment 2

[0022] Control group: traditional process: the test procedure is (1) carry out plate and frame filtration with enramycin fermented liquid, the pressure of plate and frame filtration is 0.6MPa, the pressure filtration time is 1h, and the blowing time is 0.5h; (2) the obtained The mycelium of enramycin is obtained after the filter cake is flash-dried, the inlet air temperature is 90-150°C, and the material temperature is 60-90°C. Experimental group: using the present invention: a preparation method of enramycin premix, which is characterized in that it comprises the following steps: (1) carrying out plate and frame filtration of enramycin fermented liquid; (2) flash drying of the gained filter cake Finally, obtain the mycelia of enramycin: (3) fully stir after the mycelium and auxiliary material are diluted in proportion: (4) dry after the enramycin dilution is stirred evenly, obtain enramycin pre- mixture;

[0023] The weight ratio of described step (3) enramycin mycelium and ...

Embodiment 3

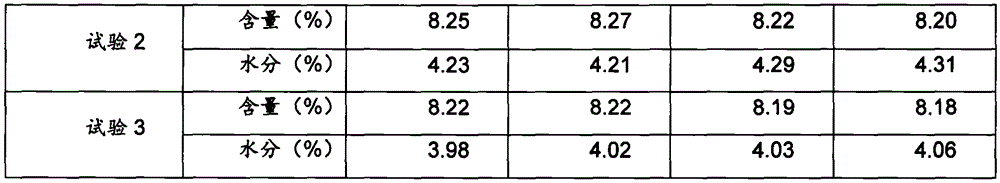

[0027] Control group: traditional process: the test procedure is (1) carry out plate and frame filtration with enramycin fermented liquid, the pressure of plate and frame filtration is 0.5MPa, the pressure filtration time is 1.5h, and blowing time is 1h; (2) obtained The mycelium of enramycin is obtained after the filter cake is flash-dried, the inlet air temperature is 90-150°C, and the material temperature is 60-90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com