Method of forming semiconductor device

A semiconductor and device technology, which is applied in the field of semiconductor device formation, can solve the problems such as the electrical performance of semiconductor devices needs to be improved, and achieve the effects of alleviating the instability effect of negative bias voltage, high uniformity of thickness, and avoiding over-etching problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It can be seen from the background art that the electrical performance of semiconductor devices formed in the prior art needs to be improved.

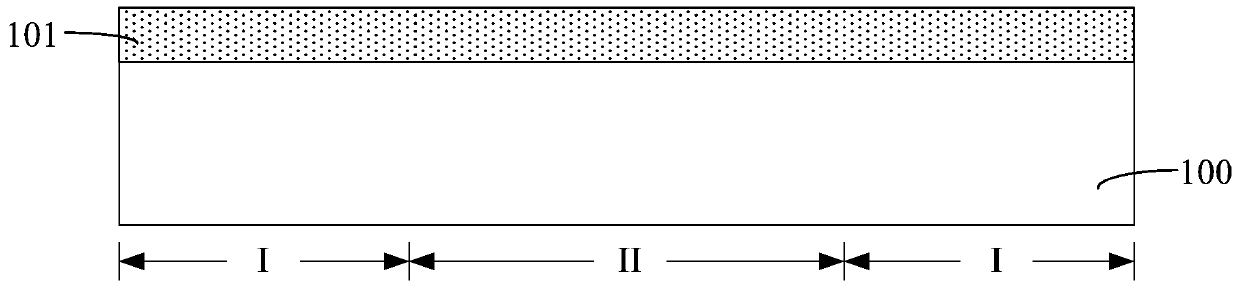

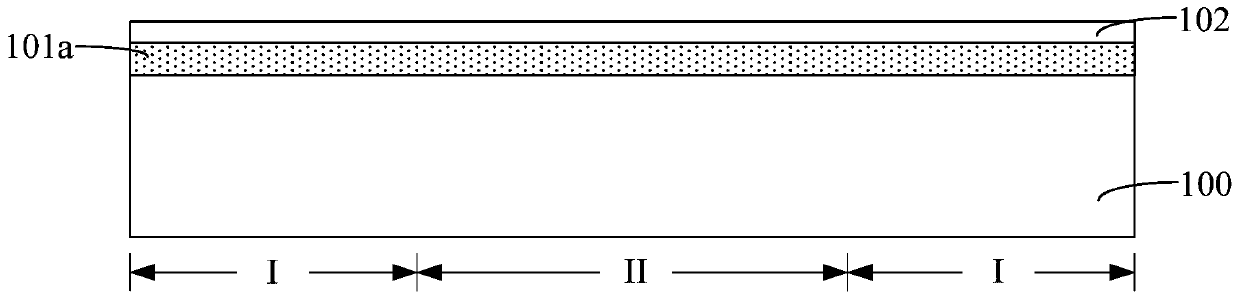

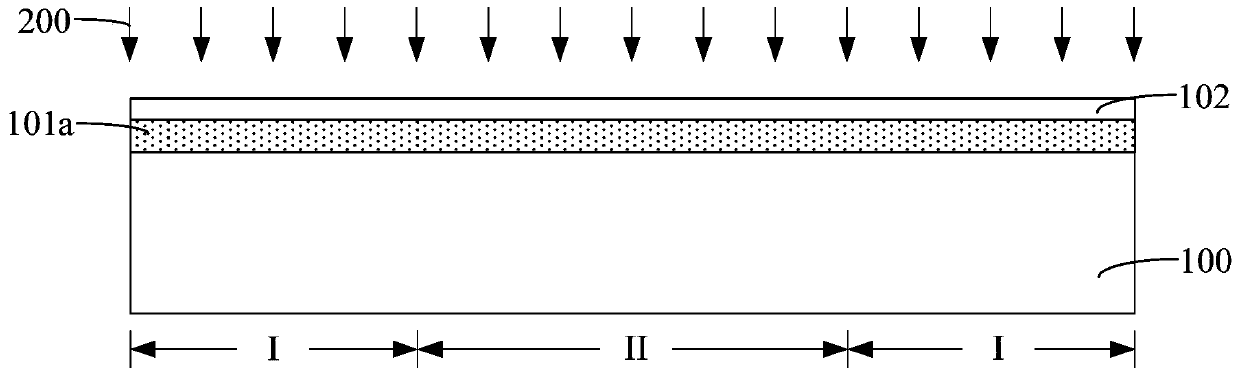

[0035] In one embodiment, when the semiconductor device includes a core device and peripheral devices, in order to meet the different requirements of the core device and peripheral devices on the thickness of the gate dielectric layer, the process steps of forming the semiconductor device include: step S1, providing a core device region and The base of the peripheral device area, forming an oxide layer on the surface of the base; step S2, forming a photoresist layer on the surface of the oxide layer in the peripheral device area; step S3, using the photoresist layer as a mask, etching Removing the oxide layer located in the core device area; then removing the photoresist layer; step S4, forming a gate dielectric film on the surface of the oxide layer in the peripheral device area and the base surface of the core device area, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com