Working medium contact cooling system of power batteries and working method of working medium contact cooling system

A cooling system, contact technology, applied in the direction of batteries, secondary batteries, circuits, etc., can solve the problems of thermal resistance, flow resistance and uneven flow, difficult heat pipe circuit layout, large space occupation, etc., to achieve heat conduction efficiency Improve, improve heat conduction efficiency, high effective utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

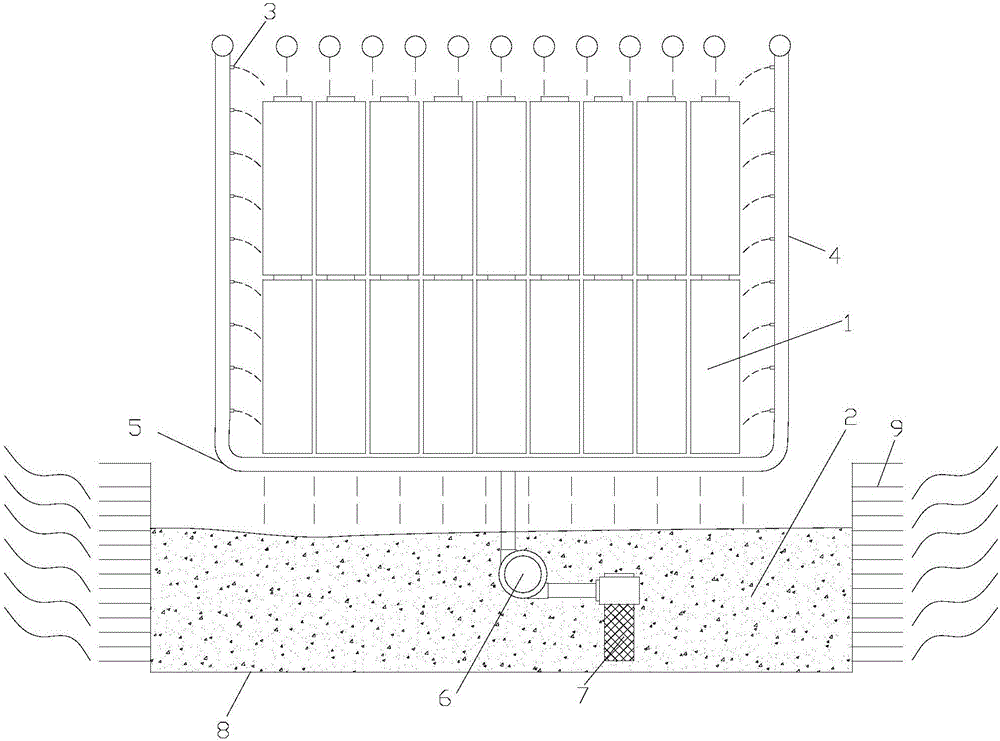

[0037] like figure 1 The working medium contact cooling system of the power battery shown includes a high-power battery pack composed of several single batteries 1, an insulating liquid heat-conducting working medium 2, a nozzle 3, a spray branch pipe 4, a spray main pipe 5, and a working medium pump 6, filter 7 and working medium box 8,

[0038] The filter 7 ensures the purity of the heat-conducting working medium 2 of the insulating liquid, and prevents impurities from damaging the working medium pump 6 and blocking the nozzle 3 .

[0039] Insulating liquid and heat-conducting working medium 2 must use good insulating heat-conducting liquid working medium, such as various types of transformer oil, heat-conducting oil, etc., to ensure the insulation of the working medium and avoid contact with the high-power battery pack 1 to cause battery damage and System scrapped. The heat-conducting working medium 2 of the insulating liquid generally has a high thermal conductivity, and...

Embodiment 2

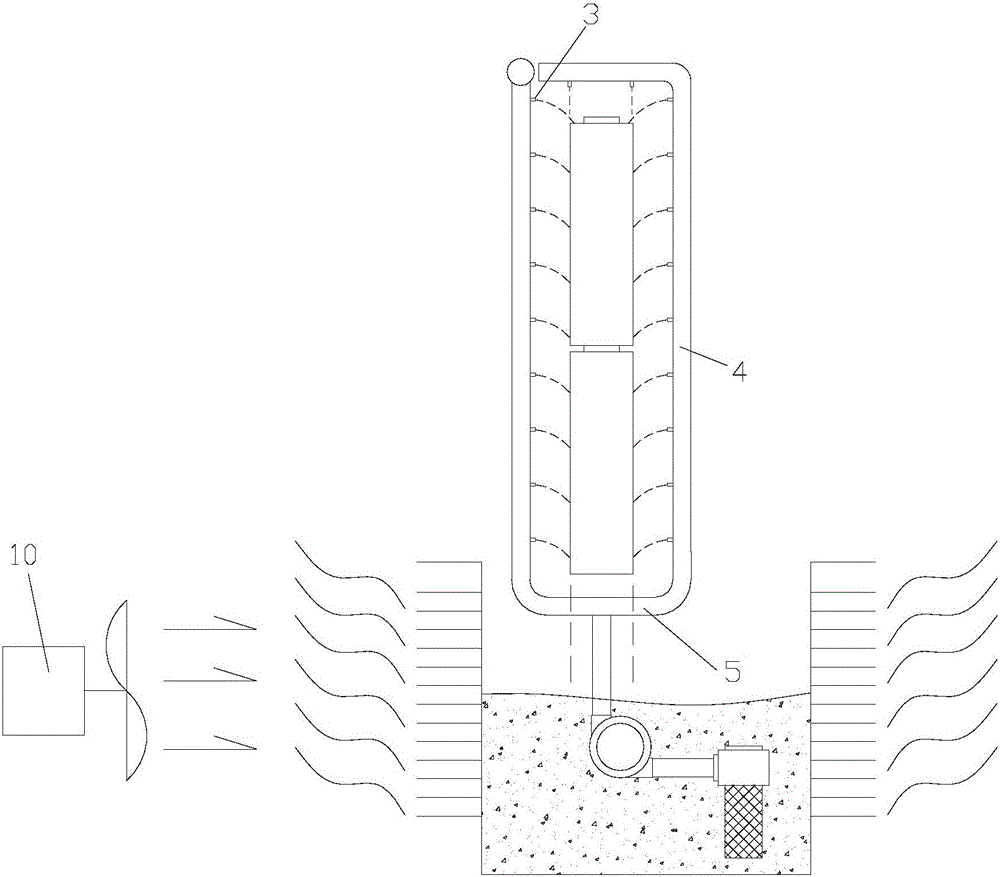

[0047] image 3 Another working fluid contact cooling system for a power battery is shown. The working fluid box 8 is provided with an air forced convection cooling structure: cooling fins 9 are installed on the outside of the working fluid box 8 , and several fans 10 are provided to blow the cooling fins 9 . Under the forced influence of external force, the air convects, and fresh air with a lower temperature is continuously blown in to exchange heat with the insulating liquid heat-conducting working medium 2 to realize cooling of the insulating liquid heat-conducting working medium 2 .

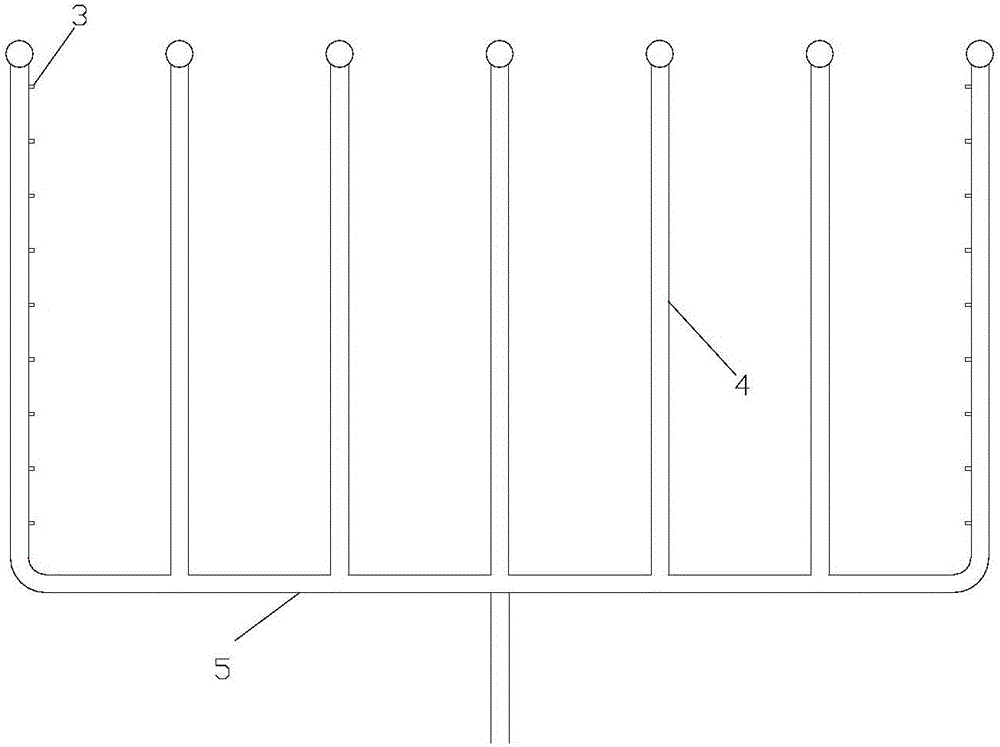

[0048] Such as Figure 4 As shown, the spray branch pipe 4 and the spray main pipe 5 form a rectangular frame.

Embodiment 3

[0050] Such as Figure 5 As shown, the working medium box 8 is provided with a water circulation cooling device: the evaporation working end 11 of the water circulation cooling device is immersed in the working medium box 8, the pipeline of the water circulation cooling device is provided with a water pump 13, and the cooling end 12 of the water circulation cooling device is carried out by a fan 10. Blast air to cool the high-temperature insulating liquid heat-conducting working medium 2 that is heat-exchanged and reflowed in the working medium box 8, and evaporate the water at the working end 11 to take the heat of the insulating liquid heat-conducting working medium 2 out to the heat-dissipating end 12 for heat dissipation. The water pump 13 circulates and continues to exchange heat with the heat-conducting working medium 2 of the insulating liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com