Method for preparing denitration catalyst from discarded vanadium and titanium based denitration catalyst

A denitration catalyst, a vanadium-titanium-based technology, applied in the field of denitration catalysts, can solve the problems of short life, poor denitration catalyst activity, low catalytic efficiency, etc., and achieve the effect of realizing reuse, realizing recyclable utilization, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

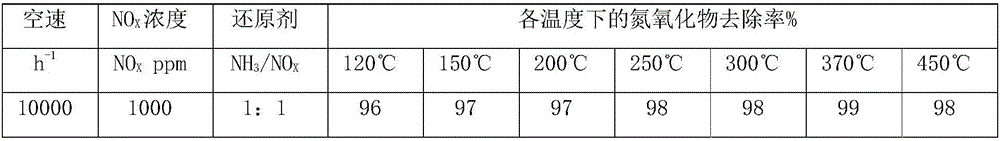

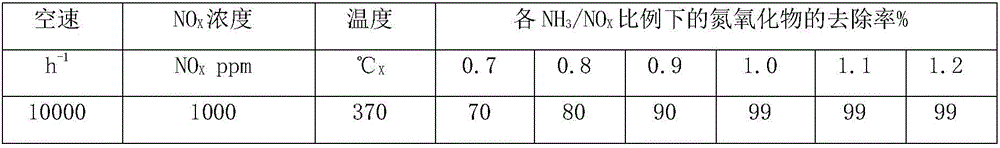

Examples

Embodiment 1

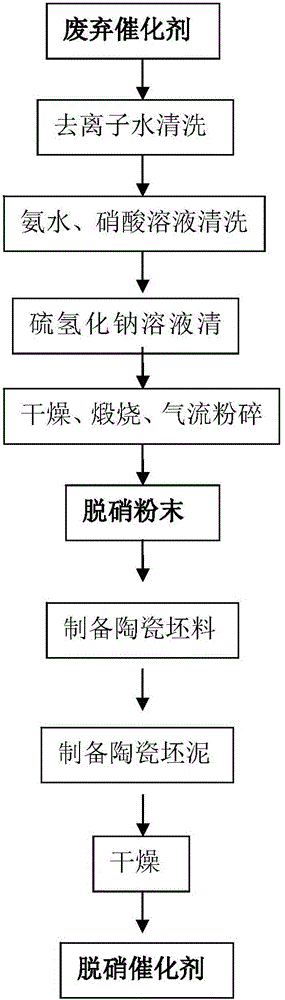

[0067] A method for preparing a denitration catalyst from waste vanadium-titanium-based denitration catalyst (it is a denitration catalyst discarded after a coal-fired power plant boiler has been used for 27010h), comprising the following steps:

[0068] (1) Preparation of vanadium-titanium-based denitration catalyst powder:

[0069] Preliminarily crush the waste vanadium-titanium-based denitrification catalyst to particles with a diameter of about 2mm, wash it with deionized water just submerged in the catalyst at room temperature to remove dust and floating matter on the surface, wash it with ammonia water (25wt%) for 20h, and then wash it with deionized water to neutrality, then wash with nitric acid solution (8wt%) for 8h, then wash with deionized water to neutrality, finally wash with sodium hydrosulfide solution (12wt%) for 8h, then wash with deionized water to neutrality; then dry at 160°C After calcination at 500° C. for 10 hours, crushing, and jet milling for 8 hours,...

Embodiment 2

[0077] A method for preparing a denitration catalyst from a waste vanadium-titanium-based denitration catalyst (which is a denitration catalyst discarded after a coal-fired power plant boiler has been used for 26880 hours), comprising the following steps:

[0078] (1) Preparation of vanadium-titanium-based denitration catalyst powder:

[0079] Preliminarily crush the waste vanadium-titanium-based denitrification catalyst to particles with a diameter of about 2mm, wash it with deionized water just submerged in the catalyst at room temperature to remove dust and floating matter on the surface, wash it with ammonia water (20wt%) for 15 hours, and then wash it with deionized water to neutrality, then wash with nitric acid solution (10wt%) for 10h, then wash with deionized water to neutrality, finally wash with sodium hydrogensulfide solution (10wt%) for 7h, then wash with deionized water to neutrality; then dry at 150°C After 9 hours, calcination at 550° C. for 12 hours, crushing,...

Embodiment 3

[0087] A method for preparing a denitration catalyst from a waste vanadium-titanium-based denitration catalyst (which is a denitration catalyst discarded after a coal-fired power plant boiler has been used for 26500h), comprising the following steps:

[0088] (1) Preparation of vanadium-titanium-based denitration catalyst powder:

[0089] Preliminarily crush the waste vanadium-titanium-based denitrification catalyst to particles with a diameter of about 2mm, wash it with deionized water just submerged in the catalyst at room temperature to remove dust and floating matter on the surface, wash it with ammonia water (30wt%) for 8 hours, and then wash it with deionized water to neutrality, then wash with nitric acid solution (4wt%) for 14h, then wash with deionized water to neutrality, finally wash with sodium hydrogensulfide solution (20wt%) for 9h, then wash with deionized water to neutrality; then dry at 120°C After 12 hours, calcination at 450° C. for 14 hours, crushing, and j...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com