Preparation method of modified lithium nickel manganese oxide cathode material, and high-voltage lithium ion battery

A technology of lithium nickel manganese oxide and positive electrode materials, which is applied in the direction of batteries, battery electrodes, secondary batteries, etc., can solve the problems of electrode material structure instability, charge and discharge capacity attenuation, electrolyte decomposition, etc., to achieve fine particle size, reduce heterogeneous, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The invention provides a method for preparing a modified lithium nickel manganese oxide positive electrode material, comprising the following steps:

[0049] A) polycondensing the phenolic compound and the aldehyde compound to obtain a phenolic resin system;

[0050] B) After mixing the phenolic resin system, lithium source, nickel source and manganese source obtained in the above steps, react to obtain a gel precursor;

[0051] C) Grinding the gel precursor obtained in the above steps after drying to obtain gel precursor powder;

[0052] D) After the gel precursor powder obtained in the above steps is sintered and annealed, it is ground again to obtain lithium nickel manganese oxide cathode material powder;

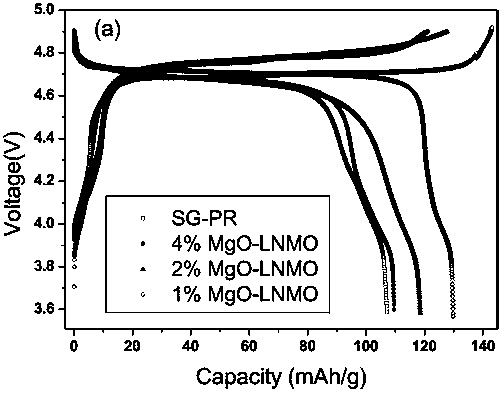

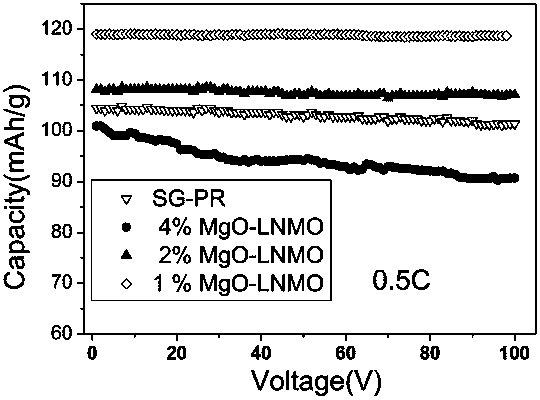

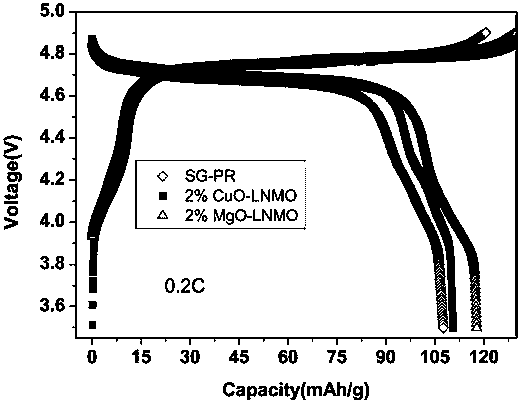

[0053] E) Dispersing and drying the above-mentioned lithium nickel manganese oxide positive electrode material powder and metal salt solution, grinding for the third time, sintering again and grinding for the fourth time to obtain the modified lithium nickel mang...

Embodiment 1

[0087] Completely dissolve resorcinol and formaldehyde in ionized water at a molar ratio of 1:1.8, and keep stirring for 35 minutes to form a phenolic resin solution.

[0088] In the phenolic resin solution that described step obtains, add the Li(Ac), Ni(Ac) that mol ratio is 1.05:0.5:1.5 2 4H 2 O and Mn(Ac) 2 4H 2 O, heated to 75°C in a water bath, and kept stirring until dehydration to form a brown wet gel, which is the gel precursor.

[0089] Then the wet gel was air-dried at 90°C for 12 hours, then transferred to a vacuum drying oven at 90°C for further drying for 12 hours, and the fully dried dry gel was fully ground and refined for 0.5 hours to obtain the gel precursor powder.

[0090] Then put the gel precursor powder in the air atmosphere of the muffle furnace at a temperature of 3°C per minute to 500°C for low-temperature pre-sintering, keep it for 4 hours to remove the organic matter in the gel, and then cool with the furnace; grind the cooled precursor for the se...

Embodiment 2

[0096] Completely dissolve resorcinol and formaldehyde in ionized water at a molar ratio of 1:2.0, and keep stirring for 40 minutes to form a phenolic resin solution.

[0097] In the phenolic resin solution that described step obtains, add the Li(Ac), Ni(Ac) that mol ratio is 1.03:0.5:1.5 2 4H 2 O and Mn(Ac) 2 4H 2 O, heated to 70°C in a water bath, and kept stirring until dehydration to form a brown wet gel, which is the gel precursor.

[0098] Then the wet gel was air-dried at 110°C for 10h, then transferred to a vacuum drying oven at 110°C for further drying for 10h, and the fully dried dry gel was fully ground and refined for 0.5h to obtain the gel precursor powder.

[0099] Then put the gel precursor powder in the air atmosphere in the muffle furnace and heat it up to 480°C at 3°C per minute for low-temperature pre-sintering, keep it warm for 5h to remove the organic matter in the gel, and then cool with the furnace; grind the cooled precursor for the second time Re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com