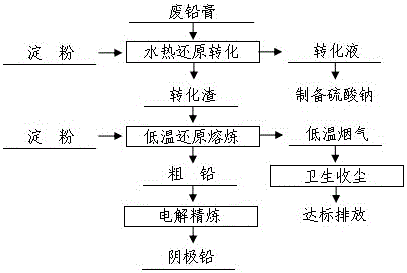

Waste diachylon hydrothermal reduction conversion and low-temperature reduction smelting method

A waste lead plaster and hydrothermal technology is applied in the fields of hydrothermal reduction and conversion of waste lead-acid battery lead plaster and low-temperature reduction smelting, which can solve the problems of difficulty in effective treatment and increase in production cost, and achieves low production cost, low labor intensity, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The main components of waste lead paste in the dismantling products of waste lead-acid batteries are (%): Pb73.80%, S5.25% and Sb0.15%, and sodium carbonate is an analytical reagent. The starch used was wheat starch. Add 2000g waste lead plaster and 356g sodium carbonate to 4000ml water to slurry at the same time, add 20g wheat starch at the same time, then add the mixed slurry to a stainless steel autoclave, control the stirring speed at 120r / min, when the nitrogen partial pressure is 0.3MPa Ventilate the kettle for 2 minutes, then heat to raise the temperature to 175°C, control the partial pressure of nitrogen to 1.2MPa and react for 4 hours. When the reaction is completed, cool down and lower the temperature to 70°C. The thermally converted slag was dried at 110°C for later use. The sulfur content in the hydrothermal reduction conversion slag is reduced to 0.02%, and the total desulfurization rate reaches 99.40%. At the same time, the lead dioxide reduction rate in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com