Delaying controlled-release acid for acidizing unblocking, preparation method of acid and acidizing unblocking method

A technology for acid release and plugging removal, which is applied in the field of acidizing plugging removal and acidizing plugging removal of oil and water wells. It can solve the problems of poor effect of acidizing plugging removal, etc., and achieve the effect of reducing the cost of measures, low requirements, and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

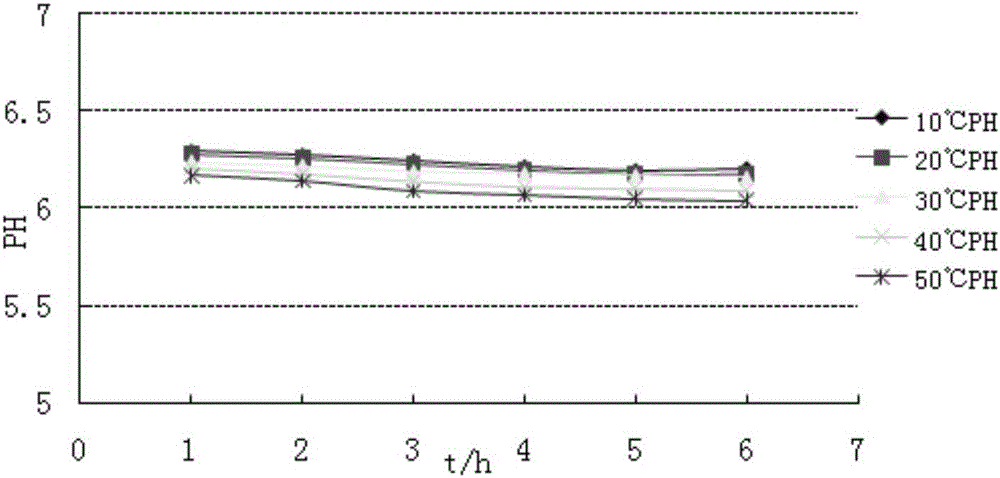

[0023] The delayed controlled-release acid used for acidification and plugging removal in this embodiment is the pre-fluid, which consists of the following components in percentage by weight: 15% propyl propionate, 8% isoamyl formate, and 8% methyl formate , 0.006% carboxylesterase, 0.2% XT-5 low penetration enhancer, 1.5% ammonium chloride, and the balance is water.

[0024] The preparation method of the above-mentioned delayed controlled-release acid comprises: adding propyl propionate, isopentyl formate, methyl formate, carboxylesterase, drainage aid, ammonium chloride and ammonium bifluoride to the water of 50% formula quantity, stir Mix well; then add the rest of the water, stir well, that is.

Embodiment 2

[0026] The delayed controlled-release acid used for acidification and plugging removal in this embodiment is the pre-fluid, which consists of the following components in percentage by weight: 12% propyl propionate, 4% isoamyl formate, 4% methyl formate , 0.006% carboxylesterase, 0.2% XT-5 low penetration enhancer, 1.5% ammonium chloride, and the balance is water.

[0027] The preparation method of the above-mentioned delayed controlled-release acid comprises: adding propyl propionate, isopentyl formate, methyl formate, carboxylesterase, drainage aid, ammonium chloride and ammonium bifluoride to the water of 40% formula quantity, stir Mix well; then add the rest of the water, stir well, that is.

Embodiment 3~5

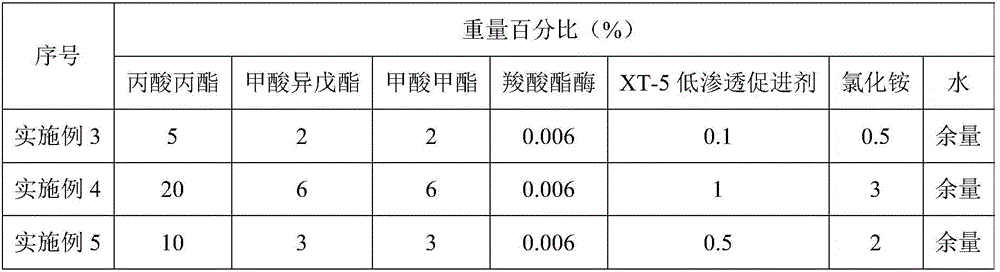

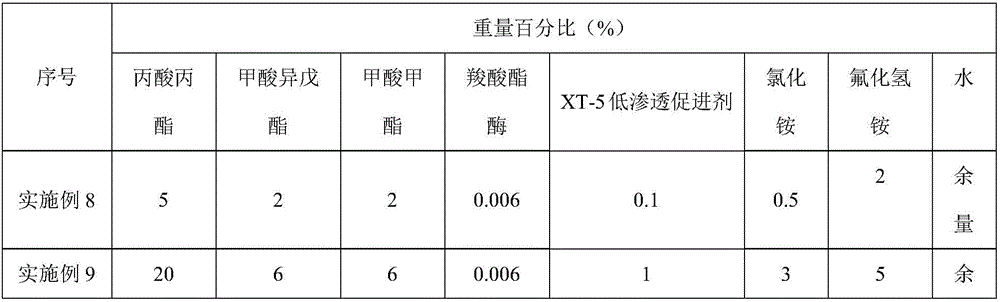

[0029] Delayed and controlled-release acid is used for acidification and plugging removal in Examples 3-5, and the delayed and controlled-release acid is used as the pre-flush, and the weight percentage composition is shown in Table 1.

[0030] The formula composition of the delayed controlled-release acid used in the acidification and blocking removal of the embodiment 3-5 of table 1

[0031]

[0032] The preparation method of the delayed controlled-release acid for acidification and blocking removal in Examples 3-5 is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com