Water-based UV anti-bacterial coating and preparing method thereof

A kind of antibacterial coating, water-based technology, applied in the field of water-based UV antibacterial coating and its preparation, can solve the problems of small impact on human health, restricted application range, low volatility, etc., and achieve the effect of convenient construction, good antibacterial effect and high curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

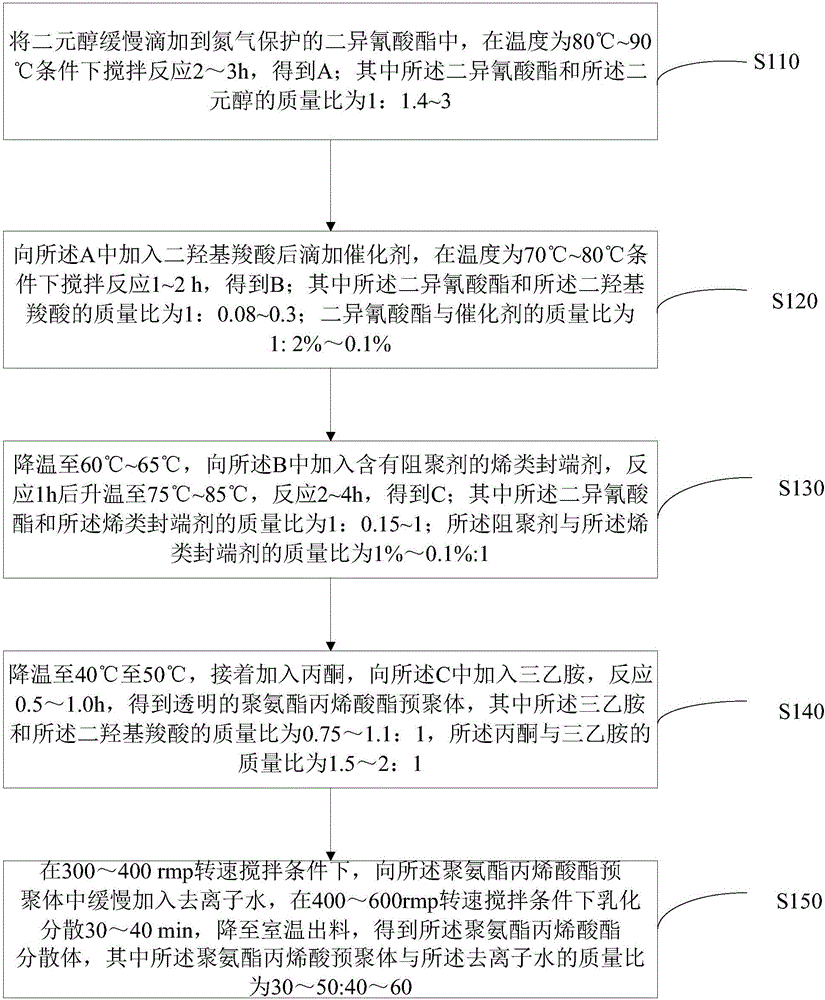

[0051] In one embodiment, a kind of preparation method of waterborne UV antibacterial coating comprises:

[0052]Add polyurethane acrylate dispersion and nano-silver sol into the dispersion kettle, stir and disperse for 0.5-1h, then add active diluent, dispersant, leveling agent, defoamer and photoinitiator, and disperse for 15-30min, using 200 ~400 mesh filter cloths are filtered to obtain the water-based UV antibacterial coating, wherein the water-based UV antibacterial coating includes the following components in parts by weight: 60-80 parts of polyurethane acrylate dispersion; 5-15 parts of nano-silver sol; 5 parts of reactive diluent ~20 parts; 3~6 parts of photoinitiator; 0.1~1 part of leveling agent; 0.1~1 part of dispersant; and 0.1~1 part of defoamer.

[0053] In one embodiment, the preparation method of polyurethane acrylate dispersion comprises:

[0054] S110, slowly drop the diol into the nitrogen-protected diisocyanate, stir and react at a temperature of 80° C. t...

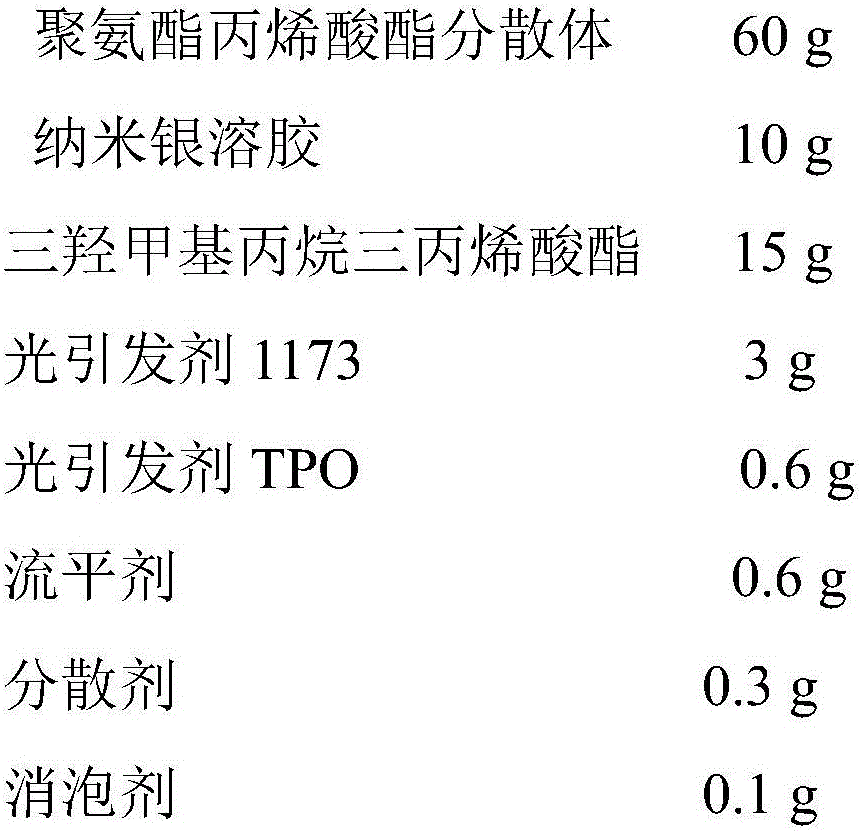

Embodiment 1

[0070] 1. Preparation of polyurethane acrylic acid dispersion:

[0071] Under the condition of nitrogen protection, add 44.5 g of isophorone diisocyanate and 62.3 g of polyether diol into a four-necked round reaction flask equipped with a thermometer, a condenser tube and a stirring rod, and stir and react at 80 ° C for 3 h ;

[0072] Continue to add 6.5g of dimethylolpropionic acid, and dropwise add the catalyst dibutyltin dilaurate 0.09g, and stir at 70°C for 2h;

[0073] Cool down to 60°C, add 20g of hydroxyethyl methacrylate mixed with 0.02g of polymerization inhibitor p-methoxyphenol, react for 1h, then raise the temperature to 75°C for 4h;

[0074] Cool down to 45°C, add 9.74g of acetone to adjust the viscosity, add 4.87g of triethylamine, react for 0.5h, and discharge to obtain a transparent polyurethane acrylate prepolymer;

[0075] Take 100 g of the above polyurethane acrylate prepolymer, slowly add 150 g of deionized water, emulsify and disperse at 400 rpm for 30 m...

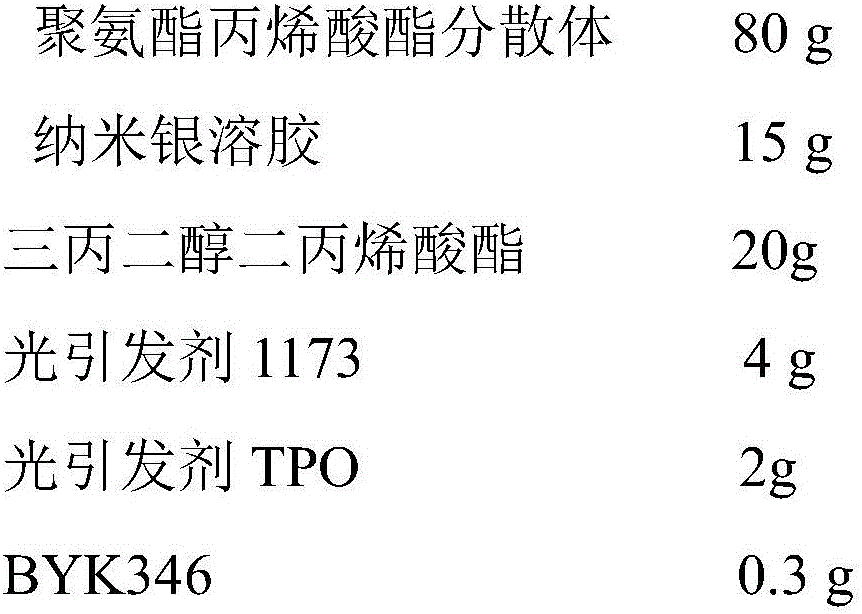

Embodiment 2

[0084] 1. Preparation of polyurethane acrylic acid dispersion:

[0085] Under nitrogen protection conditions, in the four-necked round reaction flask that thermometer, condensing tube, stirring rod are placed, add diphenylmethane diisocyanate 40g, and polyether glycol (M=500g / mol) 120g, Stir the reaction at 90°C for 2h;

[0086] Continue to add 3.2 g of dimethylol propionic acid, and dropwise add the catalyst dibutyltin dilaurate 0.04 g, and stir and react at 80°C for 3 h;

[0087] Cool down to 65°C, add 6g of hydroxyethyl acrylate mixed with 0.06g of polymerization inhibitor p-methoxyphenol, react for 1h, then raise the temperature to 85°C for 2h;

[0088] Cool down to 50°C, add 7.04g of acetone to adjust the viscosity, add 3.52g of triethylamine, react for 1h, and discharge to obtain a transparent polyurethane acrylate prepolymer;

[0089] Take 50 g of the above polyurethane acrylate prepolymer, slowly add 60 g of deionized water, emulsify and disperse at 400 rpm for 40 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com