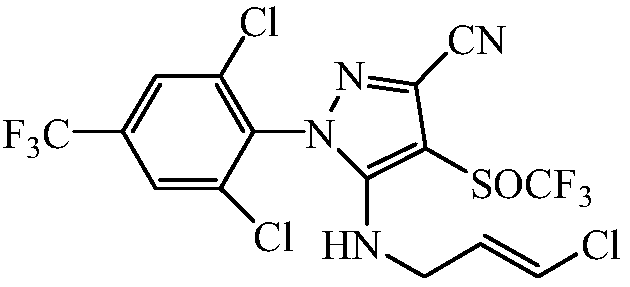

Preparation method of fipronil derivatives

A technology of fipronil and derivatives, which is applied in the field of preparation of fipronil derivative HNPC-A8008, which can solve the problems of raw material consumption and synthesis cost, difficulty in industrialization, complicated operation, etc., and achieve less three wastes and lower precipitation temperature , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

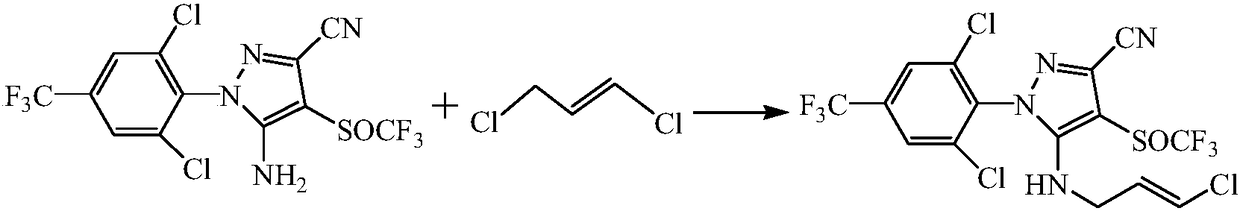

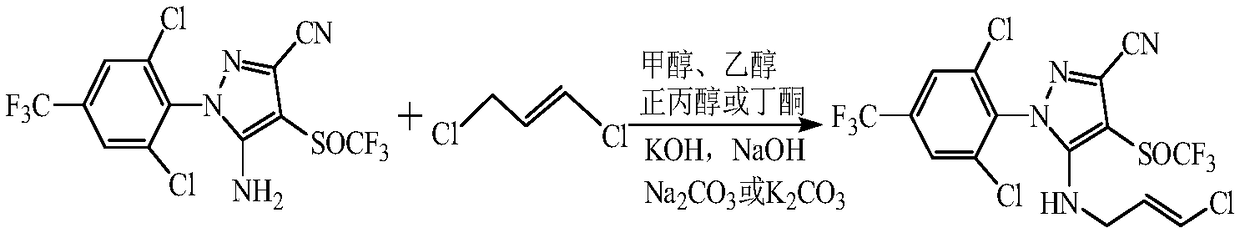

Method used

Image

Examples

Embodiment 1

[0014] Add 437.2g (1.0mol) of fipronil, 58.8g (1.05mol) KOH and 1000mL of methanol to a 3000mL three-necked flask equipped with a thermometer, condenser, constant pressure dropping funnel, and stirrer, and start stirring. 111.0 g (1.0 mol) of 1,3-transdichloropropene was added dropwise at -10°C. After the drop was complete, the temperature was controlled at -10°C for 24 hours. After the reaction is completed, filter the filtrate to adjust the pH value of the system to neutral with concentrated hydrochloric acid, recover the solvent under negative pressure below 40 ° C, slowly add the residue to ice water, control the temperature at 0 ° C ~ 5 ° C, stir and crystallize, filter, and the filter residue is reconstituted with methanol. Crystallization, filtration, and drying gave 380.6 g of white crystalline solid. The yield was 71.7%, and the quantitative analysis content by liquid chromatography was 96.4%. 1 HNMR (CDCl 3 / TMS): δ (ppm): 3.730 (d, 2H, CH 2 ), 5.681 (m, 1H, CH=),...

Embodiment 2

[0016] Add 437.2g (1.0mol) of fipronil, 159g (1.5mol) of Na 2 CO 3 and 1500mL of ethanol, start stirring, dropwise add 149.9g (1.35mol) 1,3-transdichloropropene at 10°C, after dropping, control the temperature at 20°C for 15 hours. After the reaction is completed, filter the filtrate to adjust the pH value of the system to neutral with concentrated hydrochloric acid, recover the solvent under negative pressure below 40 ° C, slowly add the residue to ice water, control the temperature at 0 ° C ~ 5 ° C, stir and crystallize, filter, and the filter residue is reconstituted with methanol. Crystallization, filtration, and drying gave 375.8 g of white crystalline solid. The yield was 70.5%, and the quantitative analysis content by liquid chromatography was 96.0%.

Embodiment 3

[0018] Add 437.2g (1.0mol) of fipronil, 179.4g (1.3mol) of K 2 CO 3 And 1300mL of n-propanol, start stirring, add 127.7g (1.15mol) of 1,3-transdichloropropene dropwise at 0°C, after dropping, control the temperature at 0°C for 22 hours. After the reaction is completed, filter the filtrate to adjust the pH value of the system to neutral with concentrated hydrochloric acid, recover the solvent under negative pressure below 40 ° C, slowly add the residue to ice water, control the temperature at 0 ° C ~ 5 ° C, stir and crystallize, filter, and the filter residue is reconstituted with methanol. Crystallization, filtration, and drying gave 386.0 g of white crystalline solid. The yield was 72.5%, and the quantitative analysis content by liquid chromatography was 96.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com