Diatomite decoration brick and molding method thereof

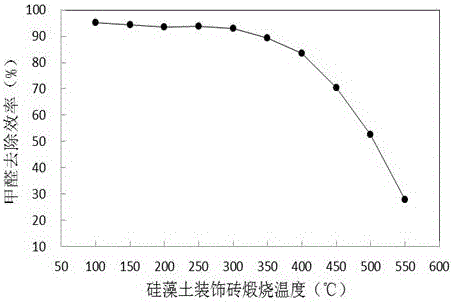

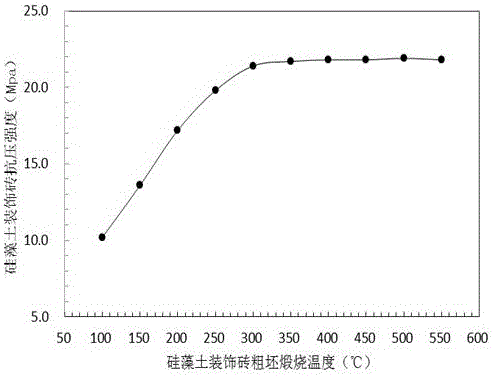

A molding method and diatomite technology, applied in the field of environmental protection decorative materials, can solve problems such as loss of air purification ability, and achieve the effects of high strength and air purification ability, high air purification ability, and excellent air purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Premixing of raw materials: 40 parts of diatomite (particle size 200 mesh), 40 parts of calcined kaolin (whiteness>95, particle size 200

[0044] mesh), 10 parts of composite inorganic binder, 3 parts of polycrystalline mullite ceramic fiber (whiteness>90) and 5 parts of iron oxide red pigment are mixed evenly; among them, silica sol in composite inorganic binder: aluminum sol: The weight ratio of potassium phosphate is 1:1:0.26;

[0045] (2) Compression molding: Spray and moisten the above-mentioned premixed raw materials and place them in a mold for compression molding, and store them in a cool place.

[0046] After drying, the mold is removed to obtain a rough billet;

[0047] (3) Low-temperature calcination: put the above-mentioned shaped rough body into a tunnel kiln for calcination, the calcination temperature is 200°C, the calcination time is 6 hours, and the product is obtained after cooling.

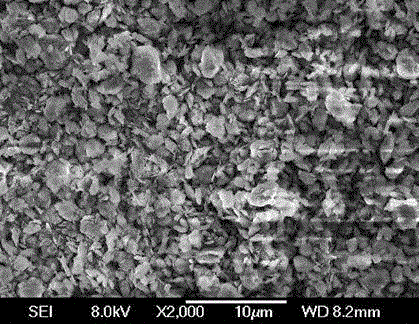

[0048] figure 1 The scanning electron micrograph of the sect...

Embodiment 2

[0051] (1) Raw material premixing: 50 parts of diatomite (particle size 400 mesh), 30 parts of calcined kaolin (whiteness>95, particle size 200

[0052] mesh), 6 parts of composite inorganic binder, 5 parts of polycrystalline mullite ceramic fiber (whiteness>90) and 3 parts of iron oxide yellow pigment are mixed evenly; among them, silica sol in composite inorganic binder: aluminum sol: The weight ratio of sodium phosphate is 1:1:0.25;

[0053] (2) Compression molding: Spray and moisten the above-mentioned premixed raw materials and place them in a mold for compression molding, and store them in a cool place.

[0054] After drying, the mold is removed to obtain a rough billet;

[0055] (3) Low-temperature calcination: put the above-mentioned formed rough body into a tunnel kiln for calcination, the calcination temperature is 250°C, the calcination time is 5 hours, and the product is obtained after cooling.

[0056] The compressive strength of the diatomite decorative brick obt...

Embodiment 3

[0058] (1) Raw material premixing: 30 parts of diatomite (particle size 500 mesh), 20 parts of calcined kaolin (whiteness>95, particle size 150

[0059] mesh), 5 parts of composite inorganic binder, 2 parts of polycrystalline mullite ceramic fiber (whiteness>90) and 2 parts of cobalt blue pigment are mixed evenly; among them, in the composite inorganic binder, silica sol: aluminum sol: phosphoric acid The weight ratio of sodium is 1:1:0.2;

[0060] (2) Compression molding: Spray and moisten the above-mentioned premixed raw materials and place them in a mold for compression molding, and store them in a cool place.

[0061] After drying, the mold is removed to obtain a rough billet;

[0062] (3) Low-temperature calcination: put the formed rough body into a tunnel kiln for calcination, the calcination temperature is 350°C, the calcination time is 3 hours, and the product is obtained after cooling.

[0063] The compressive strength of the diatomite decorative brick obtained in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com