Preparation method for aluminum buckle plate capable of purifying air and prepared aluminum buckle plate thereof

A technology for purifying air and aluminum gussets, applied in anodizing, coating, metal material coating processes, etc., to achieve the effects of thorough degreasing, good air purification ability, and super anti-fouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a method for preparing an aluminum gusset that can purify the air. The method includes the following steps: treatment of the aluminum gusset: degreasing the surface of the aluminum gusset, and then pre-coating the acrylic resin on the aluminum gusset by roll coating. The surface of the gusset plate is dried; the degreasing method of the aluminum gusset plate is as follows: firstly, the aluminum gusset plate to be treated is immersed in weak alkaline dewaxing water for 3 minutes, then soaked in trichlorethylene for rough degreasing, and then emulsified skim. Wherein the method of wax removal by water is ultrasonic wax removal, and the emulsification and degreasing method is as follows: configure an emulsion, stir the emulsifier at a pH of 9 and a temperature of 25°C for 10 minutes to obtain an emulsion, and the emulsifier includes an organic solvent , surfactant and weak alkaline cleaning agent, the ratio of the organic solvent, surfactant and we...

Embodiment 2~7

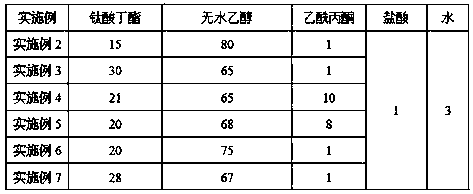

[0031] Examples 2-7 selected titanium sources, solvents, chelating agents, acid solutions and water with different volume ratios, and the specific ratios are shown in Table 1.

[0032] Aluminum gusset plate treatment: degrease the surface of the aluminum gusset plate, and then pre-coat the acrylic resin on the surface of the aluminum gusset plate by rolling coating process, and dry; the degreasing method of the aluminum gusset plate is: The board is soaked in weak alkaline dewaxing water for 3 minutes, then soaked in trichlorethylene for rough degreasing, and then emulsified degreasing. Wherein the method of wax removal by water is ultrasonic wax removal, and the emulsification and degreasing method is as follows: configure the emulsion, adjust the pH of the emulsifier to 9, and stir at a temperature of 25°C for 10 minutes to obtain the emulsion. The emulsifier includes organic Solvent, surfactant and weak alkaline cleaning agent, the ratio of the organic solvent, surfactant a...

Embodiment 8

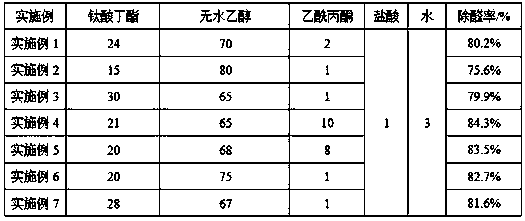

[0044] The method of this example is basically similar to that of Example 4, the difference is that the emulsification degreasing method is as follows: configure the emulsion, the pH is 10, and the temperature is 50°C, dipping or spraying the emulsion onto the surface of the aluminum gusset plate, The emulsifier includes an organic solvent, a surfactant and a weakly alkaline cleaning agent, and the ratio of the organic solvent, the surfactant and the weakly alkaline cleaning agent is 85:10:5. The aluminum gusset plate prepared in Example 8 was tested for aldehyde removal rate, and the test result showed that the aldehyde removal rate was 80.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com