A kind of titanium dioxide nanometer microsphere and its preparation method and application

A nano-microsphere and titanium dioxide technology, applied in the field of nano-materials, can solve the problems of easy compounding, limited practical application, and low solar energy utilization rate, and achieve the effects of good repeatability, improved photocatalytic performance, and strong visible light absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Titanium Dioxide Nanospheres Exposing [001] Crystal Plane

[0038] Titanium flakes (50mm×15mm, 0.25mm) were ultrasonically degreased through acetone, isopropanol and methanol in turn, rinsed with deionized water, dried under nitrogen, put into an autoclave, and added 60mL of 0.5% Hydrofluoric acid solution was heated at a constant temperature of 180°C for 3h, and the autoclave was naturally cooled to room temperature. The obtained sample was washed with deionized water, dried under nitrogen, placed in a muffle furnace, and calcined at 600°C for 1.5h to obtain TiO 2 (001) Photocatalyst.

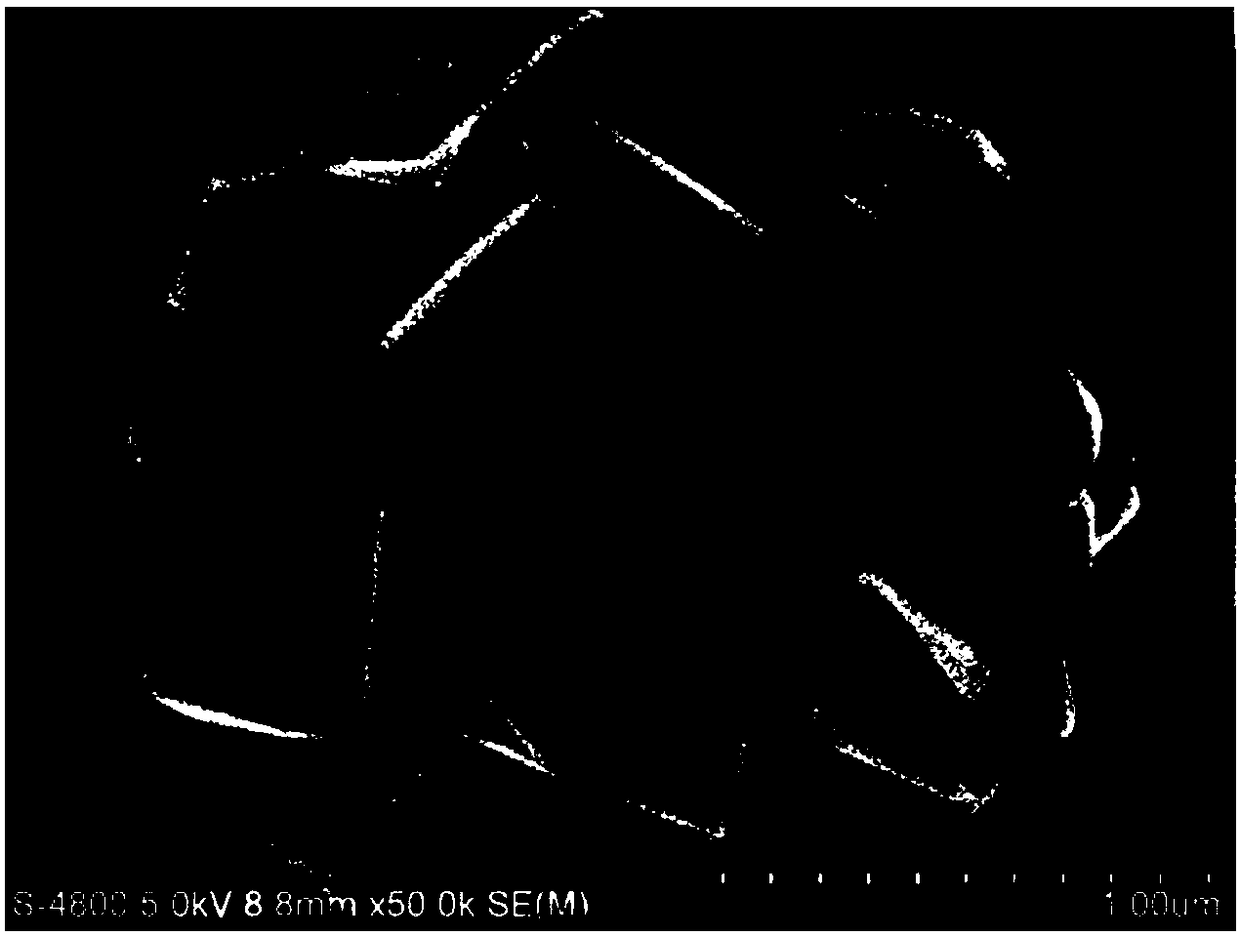

[0039] Such as figure 1 As shown, the TiO was observed with a scanning electron microscope (SEM) 2 (001) Morphology of the catalyst. The size of the titanium dioxide microspheres exposed to the [001] crystal plane obtained by the above method is about 2 μm, and the exposed surface is a square [001] crystal plane with a side length of about 0.6 μm.

Embodiment 2

[0041] Preparation of Titanium Dioxide Nanospheres Exposing [001] Crystal Plane

[0042] Firstly, the titanium flakes (50mm×15mm, 0.5mm) were ultrasonically degreased through acetone, isopropanol and methanol, then rinsed with deionized water, dried under nitrogen, put into an autoclave, and added 60mL of 0.3% by volume Hydrofluoric acid solution was heated at a constant temperature of 180°C for 3h, and the autoclave was naturally cooled to room temperature. The obtained sample was washed with deionized water, dried under nitrogen, placed in a muffle furnace, and calcined at 600°C for 1.5h to obtain TiO 2 catalyst of light.

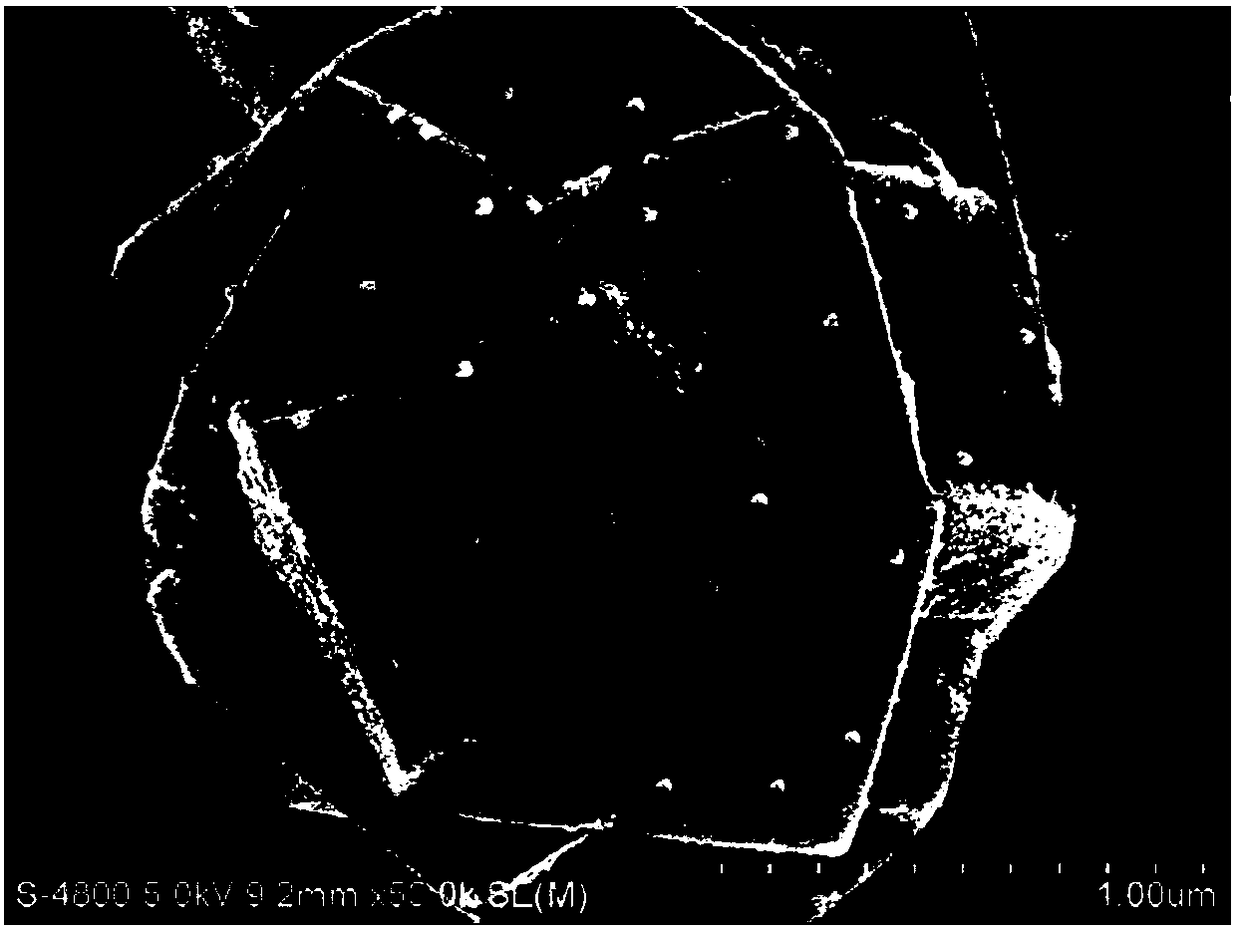

[0043] Such as figure 2 As shown, the TiO was observed with a scanning electron microscope (SEM) 2 Morphology of the catalyst, the prepared TiO 2TiO is a truncated biconical decahedron and cannot form a microsphere structure 2 .

Embodiment 3

[0045] Preparation of Nitrogen and SnO Co-modified TiO Nanospheres with Exposed [001] Facets

[0046] With the TiO obtained in embodiment 1 2 (001) soaked in 1M ammonia water for 16h, and calcined in a muffle furnace at 450°C for 1.5h to obtain N-TiO 2 (001), then the N-TiO 2 (001) into the autoclave, add 5mg / mL SnCl 4 ·5H 2 The mixed solution of O in ethanol was hydrothermally reacted at 150°C for 12h, and SnO was prepared after washing and drying. 2 / N-TiO 2 (001).

[0047] Such as image 3 As shown, the SnO was observed with a scanning electron microscope (SEM) 2 / N-TiO 2 (001) Morphology of the catalyst. The titanium dioxide microspheres co-modified with nitrogen and tin oxide obtained by the above method have a size of about 2 μm, SnO 2 Nanoparticles uniformly dispersed in N-TiO 2 (001) surface.

[0048] Further observation of SnO by transmission electron microscopy 2 / N-TiO 2 (001) Photocatalyst. Depend on Figure 4 It can be seen that the lattice fringes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com