A piston type two-component glue container

A two-component adhesive and piston-type technology, which is applied to containers, containers with multiple items, and caps with auxiliary devices, etc., can solve problems such as uniformity of difficult rubber materials, troublesome cleaning, and large surface area of paddles. Good stirring speed and effect, easy to carry and use, small internal surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

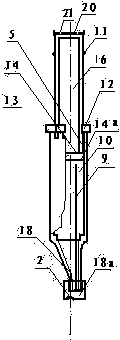

[0031] Such as figure 1 As shown, the upper container 10 is set outside the lower container 16. The inner wall of the upper container has an elastic membrane 5 that is watertightly matched with the outer wall of the lower container. The strip stirring rod on the inner side of the cover 18a deviates from the central axis of the cylinder; and a transmission notch 2 is set on the cover at the central axis of the cylinder, which can be used to cooperate with the electric drill or the opener to rotate, and certainly also can be provided on the outside of the cover. A longitudinal convex groove or a ring groove and a pull wire wound therein are provided on the outside of the cover to facilitate manual rotation (not shown); at the tail of the upper container 10, there are evenly distributed ring blocks 12 formed by dividing by several longitudinal slits 13, Its end protrudes inwardly and can cooperate with the upper and lower two sections of ring grooves 11 of the lower container 16 ...

Embodiment 2

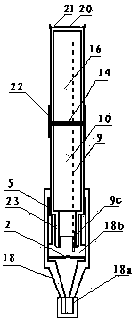

[0033] Such as figure 2As shown, the upper and lower containers 10, 16 can also be watertightly fixed together by the sealing sleeve 22, and the diaphragm 14 can also be directly arranged in a container to separate it into an upper container 10 and a lower container 16, and the upper container has a larger neck. To ensure that the external stirring rod 9 plugged in by the socket 9c in the rotating cover 18b that is enclosed within it can rotate normally, the boss where the socket 9c is located stretches into the neck and acts as an inner cover. The cooperation between the rotating cover 18b and the neck of the upper container 10 can be coordinated with rotatable gaps such as oil seals, O-shaped sealing rings, and sealed with a film before use. On the rotary cover 18b, the central axis position of the container cylinder is provided with a transmission notch 2 that can be driven by an electric drill to rotate the stirring rod 9, and a tapered glue injection nozzle 18 with an ou...

Embodiment 3

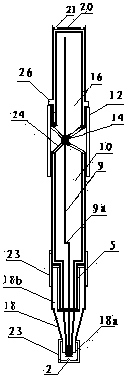

[0035] Such as image 3 As shown, the open ends of the hard plastic upper container 10 and the lower container 16 of two uniform cross-sections can also be thermally sealed together with a plastic film bag 24 to form a unified closed space. The bottom 20 of the lower container has a pre-cut ring 21 formed by pre-punching with ring-shaped punching marks, which will be separated from the main body when pushed hard. One end is bonded and fixed on the plastic stirring rod 9 in the jack of the inner side of the rotary cover 18b. The radius rotates around the central axis of the container, and the boss where the socket on the inside of the rotating cover 18b is located acts as an inner plug. Bind the middle part of the film bag with a rope, and form an isolation layer 14 by bundling, folding and clamp fastening etc. on the stirring rod at the position. The gap between the upper and lower containers near the isolation layer 14 is fitted with a rigid ring 12 whose axial length is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com