High-compaction density silicon-carbon negative electrode material and preparation method and application thereof

A negative electrode material and compaction density technology, applied in the field of high compacted density silicon carbon negative electrode materials, can solve the problems of poor cycle stability and low efficiency, and achieve the effects of low cost, high degree of practicality, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

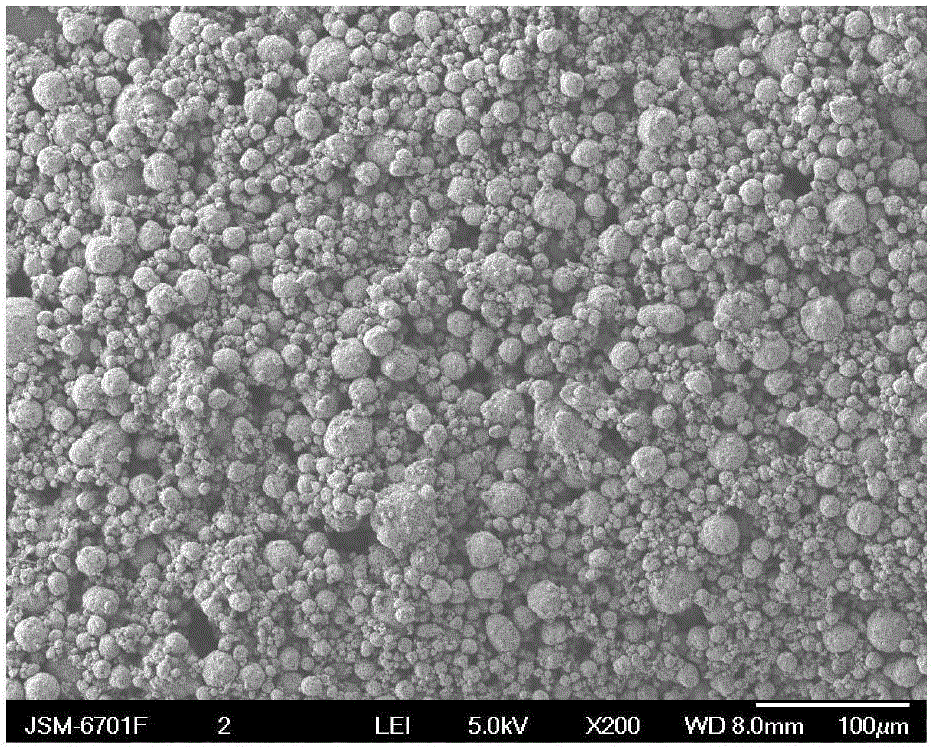

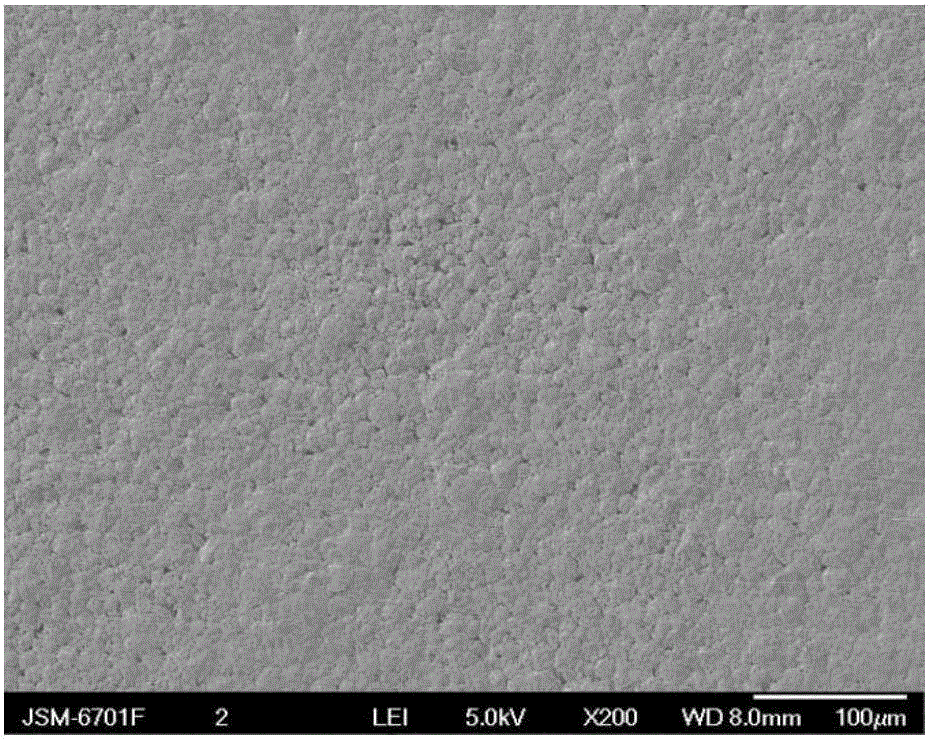

Embodiment 1

[0029]The silicon powder with an average particle size of 1 μm, chitosan, and phenolic resin are wet ball-milled in an aqueous solution, the mass ratio of silicon powder, chitosan, and phenolic resin is 1:1:1, and the speed of the ball mill is 900r / min , after grinding for 3 hours, adjust the speed of the ball mill to 500r / min, and add three kinds of graphite flakes with different particle sizes but the same quality, wherein the average particle size of the graphite flakes is 1 μm, 5 μm, and 10 μm, and the silicon powder and the total The mass ratio of flake graphite was 1:6, and a uniformly mixed slurry was obtained after ball milling for 1 hour. The obtained slurry is shaped by an open spray dryer. The atomizer of the spray dryer is a two-fluid atomizer, the gas used is air, the inlet temperature is 200°C, the outlet temperature is 100°C, and the airflow It is 8L / min, and the feed rate is 30r / min. The obtained material was sintered at 700° C. for 2 h in an argon atmosphere,...

Embodiment 2

[0034] The silica powder with an average particle size of 1 μm, sucrose, and asphalt were wet-milled in an aqueous solution. The mass ratio of silicon powder, sucrose, and asphalt was 1:1:1, and the speed of the ball mill was 900r / min. After grinding for 3 hours, the Adjust the speed of the ball mill to 500r / min, and add three types of graphite flakes with different particle sizes but the same quality, wherein the average particle size of the graphite flakes is 1 μm, 5 μm, and 10 μm, and the mass ratio of silicon powder to the total graphite flakes is 1 :7, after ball milling for 1h, a homogeneous slurry was obtained. The obtained slurry is shaped by an open spray dryer. The atomizer of the spray dryer is a two-fluid atomizer, the gas used is air, the inlet temperature is 200°C, the outlet temperature is 100°C, and the airflow It is 8L / min, and the feed rate is 30r / min. The obtained material was sintered at 700° C. for 2 h in an argon atmosphere, and the heating rate was 7° C...

Embodiment 3

[0037] Silicon powder with an average particle size of 1 μm, glucose, and polyvinylpyrrolidone additives are wet ball-milled in an aqueous solution. The mass ratio of silicon powder to glucose and polyvinylpyrrolidone is 1:1:1, and the speed of the ball mill is 900r / min. After grinding for 3 hours, adjust the rotational speed of the ball mill to 500r / min, and add three types of graphite flakes with different particle sizes but the same quality, wherein the average particle size of the graphite flakes is 1 μm, 5 μm, and 10 μm, and the silicon powder and the total flakes The mass ratio of graphite was 1:10, and a uniformly mixed slurry was obtained after ball milling for 1 hour. The obtained slurry is shaped by an open spray dryer. The atomizer of the spray dryer is a two-fluid atomizer, the gas used is air, the inlet temperature is 200°C, the outlet temperature is 100°C, and the airflow It is 8L / min, and the feed rate is 30r / min. The obtained material was sintered at 700° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com