A kind of preparation method of supercapacitor electrode covered with active electrode film

A technology for supercapacitors and active electrodes, which is applied in the field of preparation of supercapacitor electrodes, can solve problems such as poor bonding force, poor mechanical properties, and poor conductivity, and achieve good heat resistance and thermal stability, low corrosion resistance requirements, The effect of good binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A preparation method of a supercapacitor electrode covered with an active electrode film, comprising the following steps:

[0047] S1. Using 20×10×0.2mm pure iron foil as the substrate, the conductive foil is degreased, washed with water, pickled and washed with water in sequence;

[0048] S2. Plating the treated pure iron foil in a nickel-copper-iron-phosphorus chemical plating solution at 82°C for 10-60 minutes, plating a nickel-copper-iron-phosphorus alloy film on the surface of the conductive foil and washing with water to obtain a current collector;

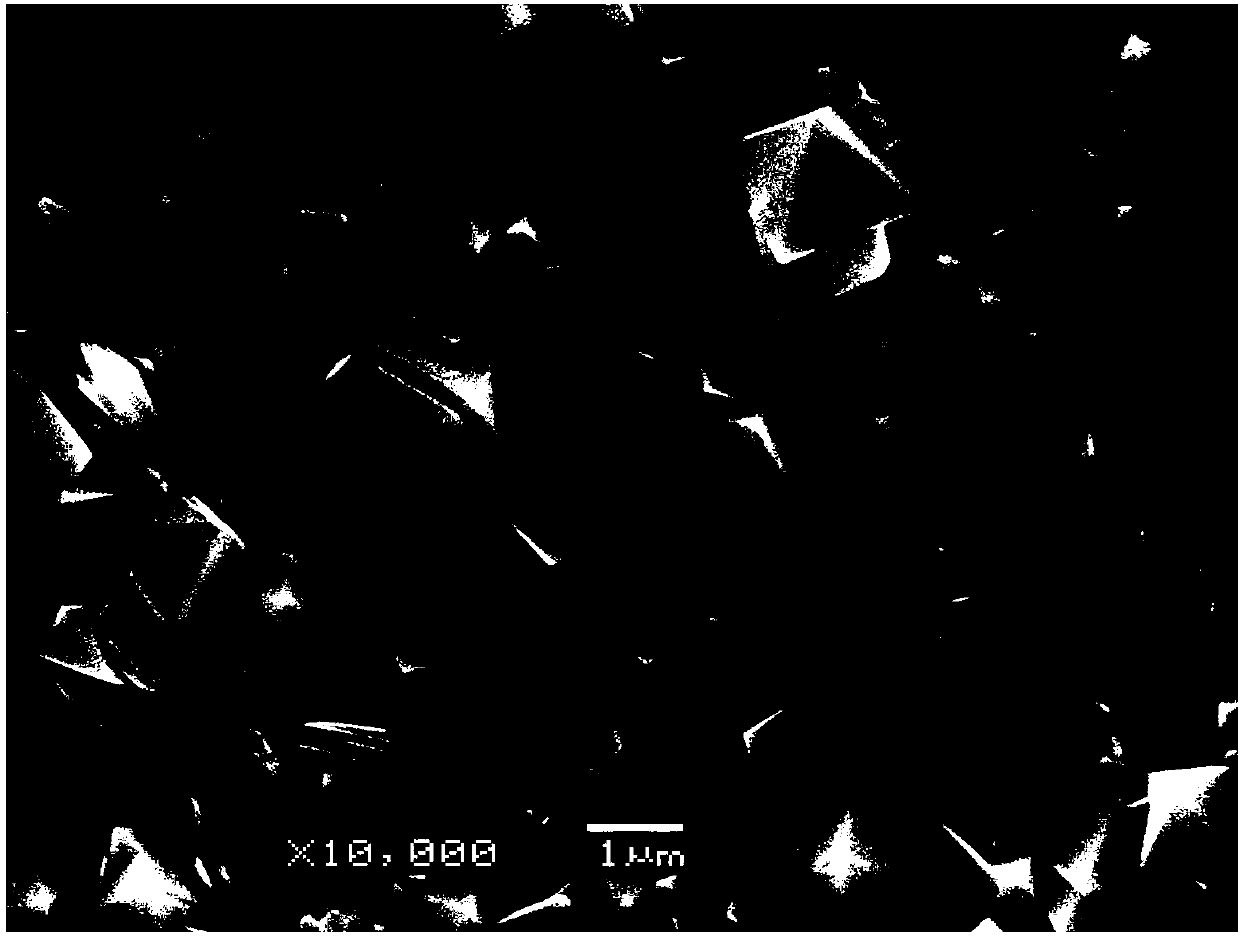

[0049] S3. Soak the current collector in 2-20mol / L potassium hydroxide solution for 1-5min, take it out and place it in a 50-200°C oven for thermal corrosion for 1-8h, synthesize hydroxide and / or oxidize in situ on the surface of the current collector compound film;

[0050] S4. Put the hot-corroded current collector in 2mol / L potassium hydroxide solution for circulation and activation for 5 weeks and then dry it. Th...

Embodiment

[0052]

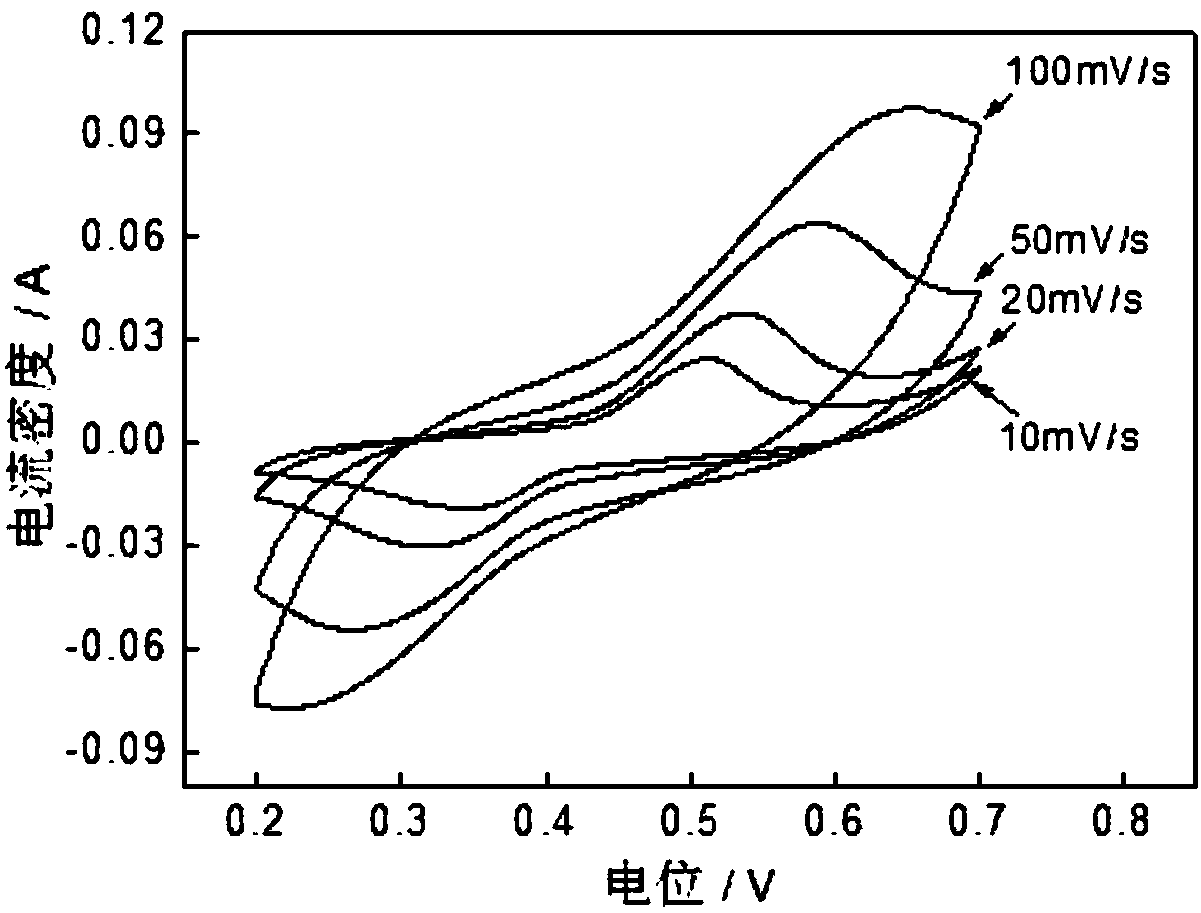

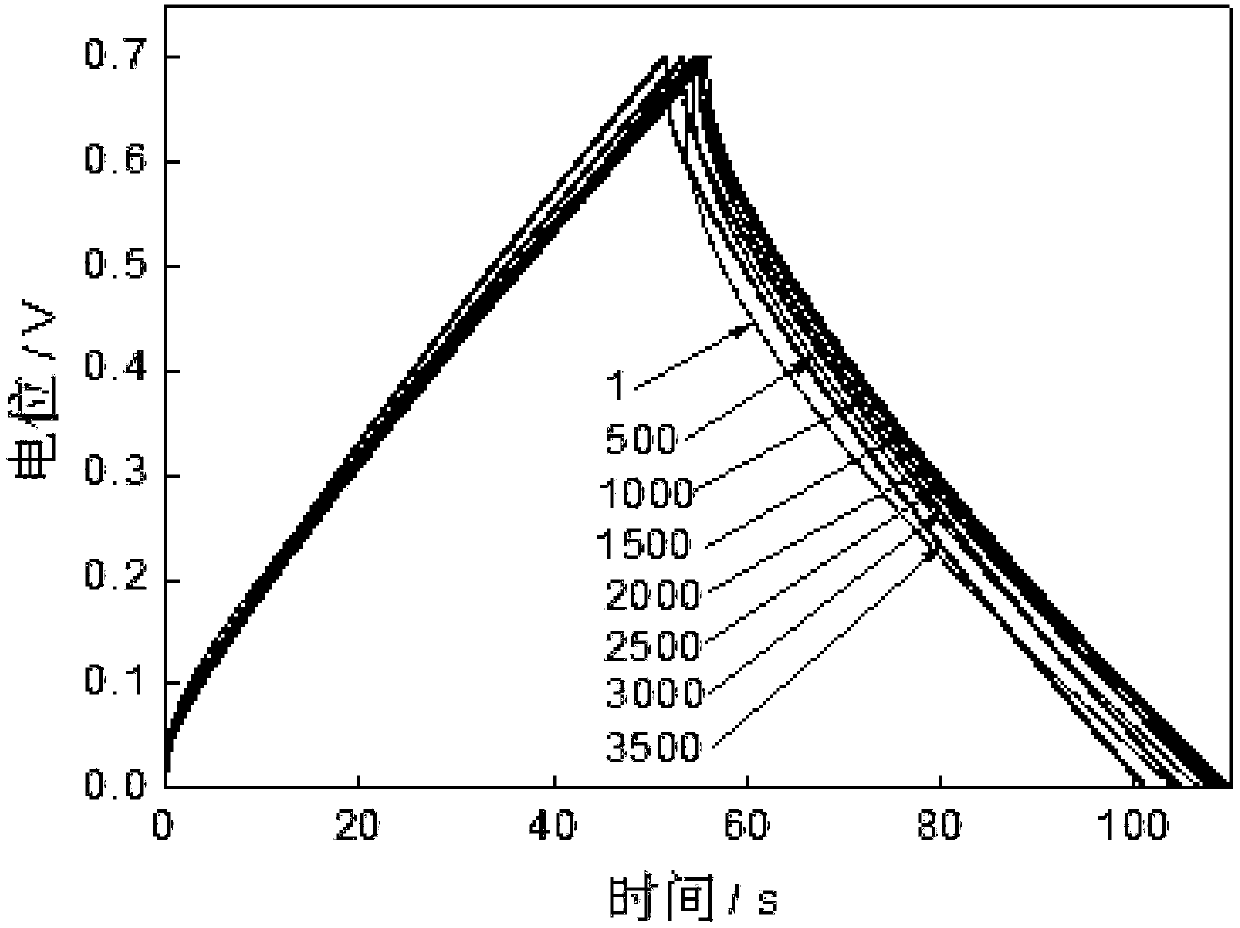

[0053] In this embodiment 1-7, use PARSTAT2273 electrochemical workstation, take Hg / HgO electrode as reference electrode, platinum electrode as auxiliary electrode, the supercapacitor electrode covered with electrode film prepared in embodiment 1-7 as working electrode, its The bare area is 1.0cm 2 , with 2mol / L KOH solution as the electrolyte, the potential window is 0.20-0.70V, and the specific capacitance (F / cm 2 ).

[0054] Energy spectrum analysis shows that in Example 1 and Example 5, the plating time is 30 minutes, and the mass percentages of Ni, Cu, Fe and P in the nickel-copper-iron-phosphorus alloy film are 40.98%, 51.42%, 3.08% and 4.52%, respectively.

[0055]Energy spectrum analysis shows that embodiment 2, embodiment 3, embodiment 4, plating time is 20min, and the mass percentages of Ni, Cu, Fe and P in the nickel-copper-iron-phosphorus alloy film are respectively 38.04%, 53.41%, 4.43% and 4.12%.

[0056] Energy spectrum analysis shows that in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com