Preparation method of anti-radiation biomimetic membrane

A radiation protection and film technology, applied in the field of preparation of radiation protection bionic films, can solve the problems of poor mechanical properties, migration out, no radiation protection performance, etc., and achieve high strength and radiation protection characteristics, simple methods, and excellent toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a radiation-proof biomimetic film, comprising the following steps:

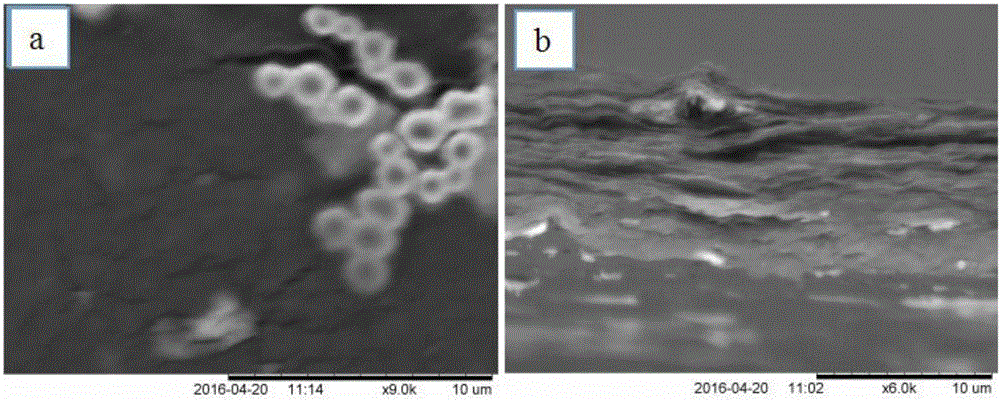

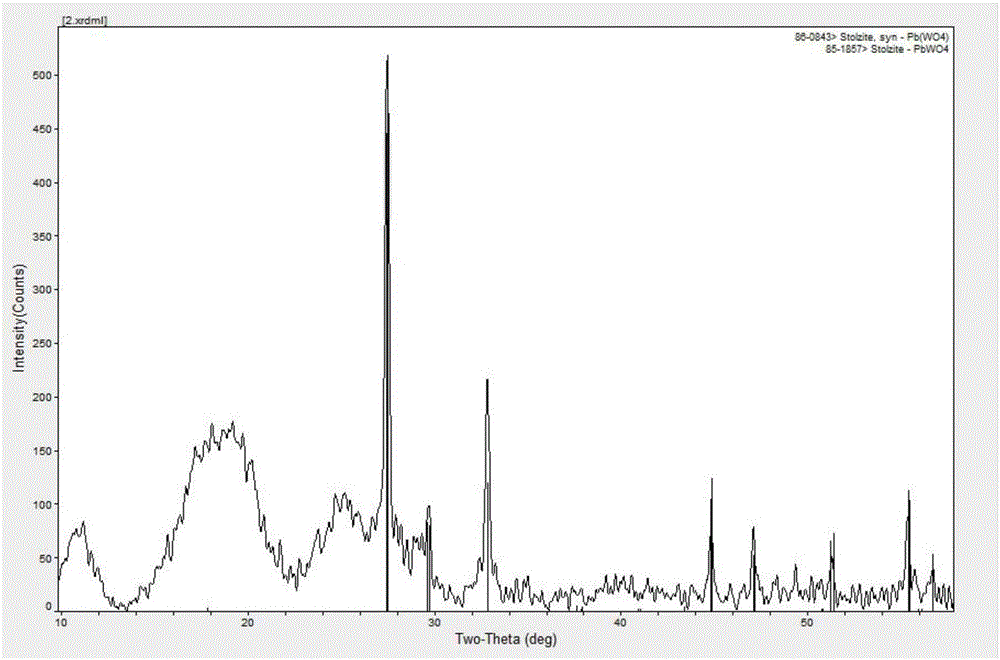

[0031] Step 1. Stir 2g of sodium-based montmorillonite into 300g of deionized water, then stir at 3000r / min for 6 days to peel off the sodium-based montmorillonite into single-layer nanosheets; the stripped mixed solution is subjected to 3000r / min× Centrifuge for 10min, take the supernatant to obtain the clay solution; stir 3g chitosan into the mixture of 300g deionized water and 3g glacial acetic acid, stir at room temperature at a speed of 3000r / min for 24 hours, then let it stand for 24 hours , get the supernatant to obtain the chitosan solution;

[0032] Step 2, get 200mL of chitosan solution prepared in step 2, under stirring at 500r / min, add 200mL of equal volume of clay solution dropwise at a rate of 5g / min. Stir at a speed of min for 12 hours to allow chitosan molecules to adsorb on the surface of the sodium-based montmorillonite nanosheets. After the adsorption reactio...

Embodiment 2

[0037] A preparation method of a radiation-proof biomimetic film, comprising the following steps:

[0038] Step 1. Stir 4g of sodium-based montmorillonite into 500g of deionized water, then stir at 5000r / min for 8 days to peel off the sodium-based montmorillonite into single-layer nanosheets; the stripped mixed solution is subjected to 3000r / min× Centrifuge for 10min, take the supernatant to obtain the clay solution; stir 6g of chitosan into the mixture of 500g of deionized water and 6g of glacial acetic acid, stir at room temperature at a speed of 5000r / min for 24 hours, then let stand for 24 hours , get the supernatant to obtain the chitosan solution;

[0039] Step 2, get 500mL of the chitosan solution prepared in step 2, under the stirring of 500r / min, dropwise add 500mL of equal volume of clay solution at a rate of 10g / min, seal after the addition is completed, Stir at a speed of min for 12 hours to allow chitosan molecules to adsorb on the surface of the sodium-based mon...

Embodiment 3

[0044] A preparation method of a radiation-proof biomimetic film, comprising the following steps:

[0045] Step 1. Stir 3g of sodium-based montmorillonite into 400g of deionized water, then stir at 4000r / min for 7 days to peel off the sodium-based montmorillonite into single-layer nanosheets; the stripped mixed solution is subjected to 3000r / min× Centrifuge for 10min, take the supernatant to obtain the clay solution; stir 5g chitosan into the mixture of 400g deionized water and 5g glacial acetic acid, stir at room temperature at a speed of 4000r / min for 24 hours, then let it stand for 24 hours , get the supernatant to obtain the chitosan solution;

[0046] Step 2, get 300mL of chitosan solution prepared in step 2, under stirring at 500r / min, add 300mL of equal volume of clay solution dropwise at a rate of 8g / min, seal after the addition is completed, Stir at a speed of min for 12 hours to allow chitosan molecules to adsorb on the surface of the sodium-based montmorillonite na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com