Corrugated paper waste recovery device

A waste recycling and recycling device technology, applied in metal processing, grain processing and other directions, can solve problems such as affecting the cleanliness of production safety sites, complex production processes, and increasing labor workload, and achieve safe production, convenient use, and realization of The effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

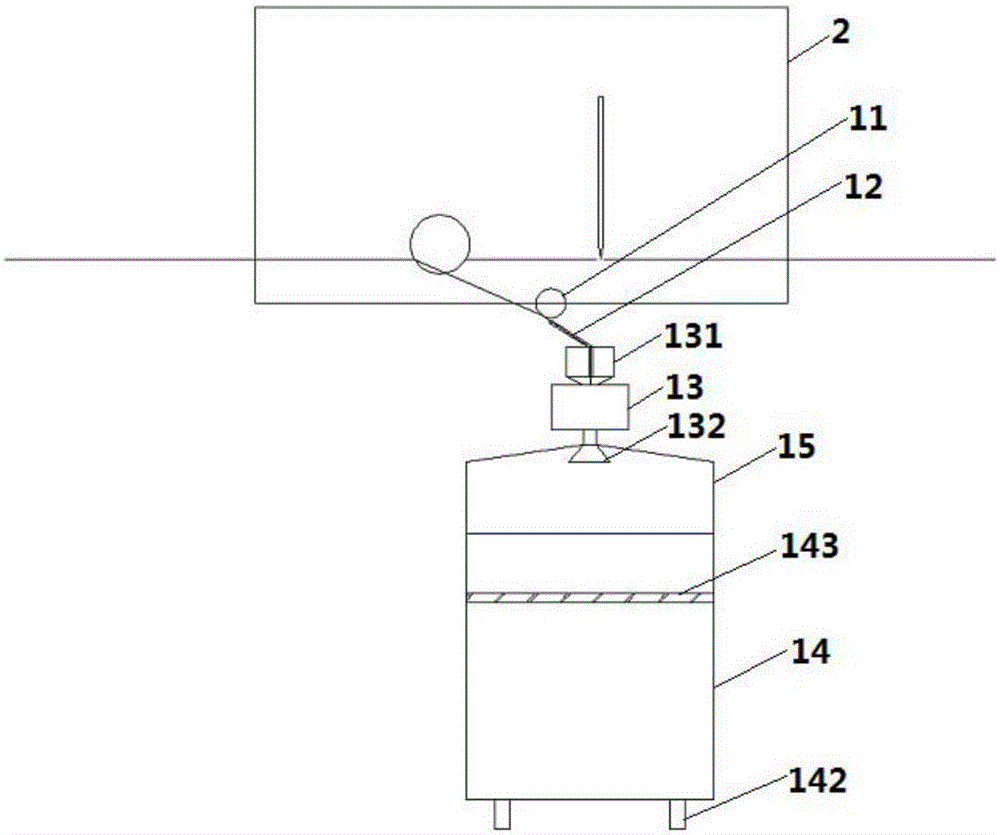

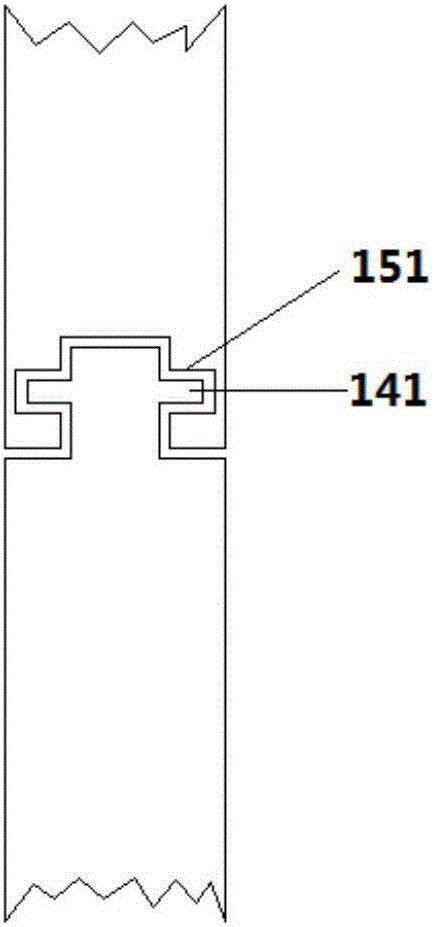

[0015] A corrugated paper waste recovery device, the recovery device 1 is located at the paper outlet of the rotary cutting machine 2, the recovery device 1 is composed of a guide wheel 11, a material guide pipe 12, a crusher 13, and a recovery box 14, the guide wheel 11 Located at the paper outlet of the rotary cutting machine 2, the material guide pipe 12 is located under the guide wheel 11, the feed port 131 of the crusher 13 and the bottom nozzle of the material guide tube 12 are located below, and the recovery box 14 is located at the outlet of the crusher 13. Below the feed port 132, the discharge port 132 of the crusher 13 is connected and fixed with a box cover 15, the shape and size of the cover mouth of the box cover 15 is the same as the box mouth of the recovery box 14, and the side of the cover mouth parallel to the corrugated cardboard Slot 151 is provided, and the box mouth is provided with the clip 141 that matches with slot 151, and clip 141 is inserted in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com