Method and device for plasma producing hydrogen by using garbage biomass and water as raw material

A plasma and biomass technology, applied in the field of hydrogen energy production, can solve the problems of impracticability, high energy consumption of electrolytic hydrogen production, and low-cost hydrogen production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

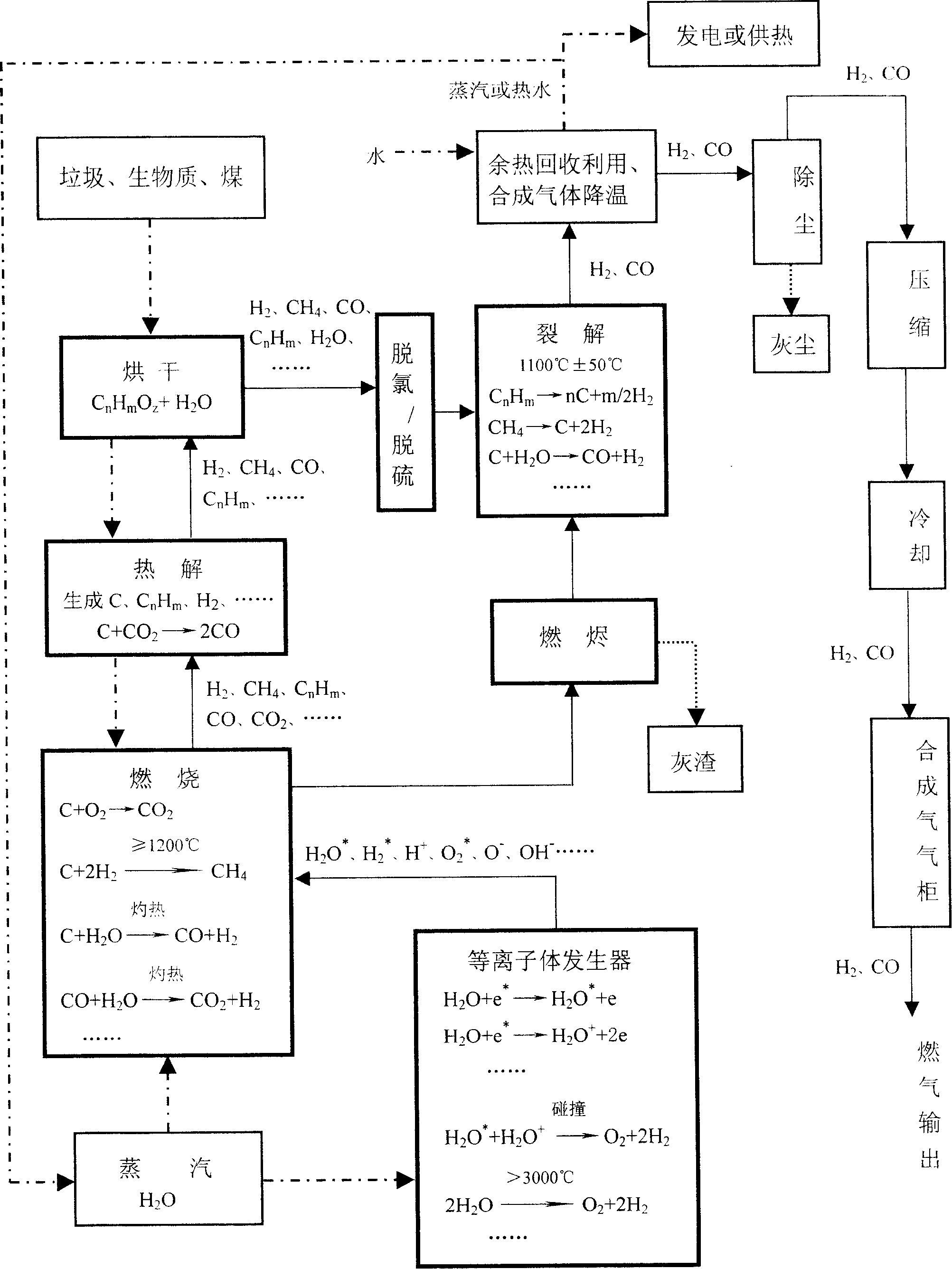

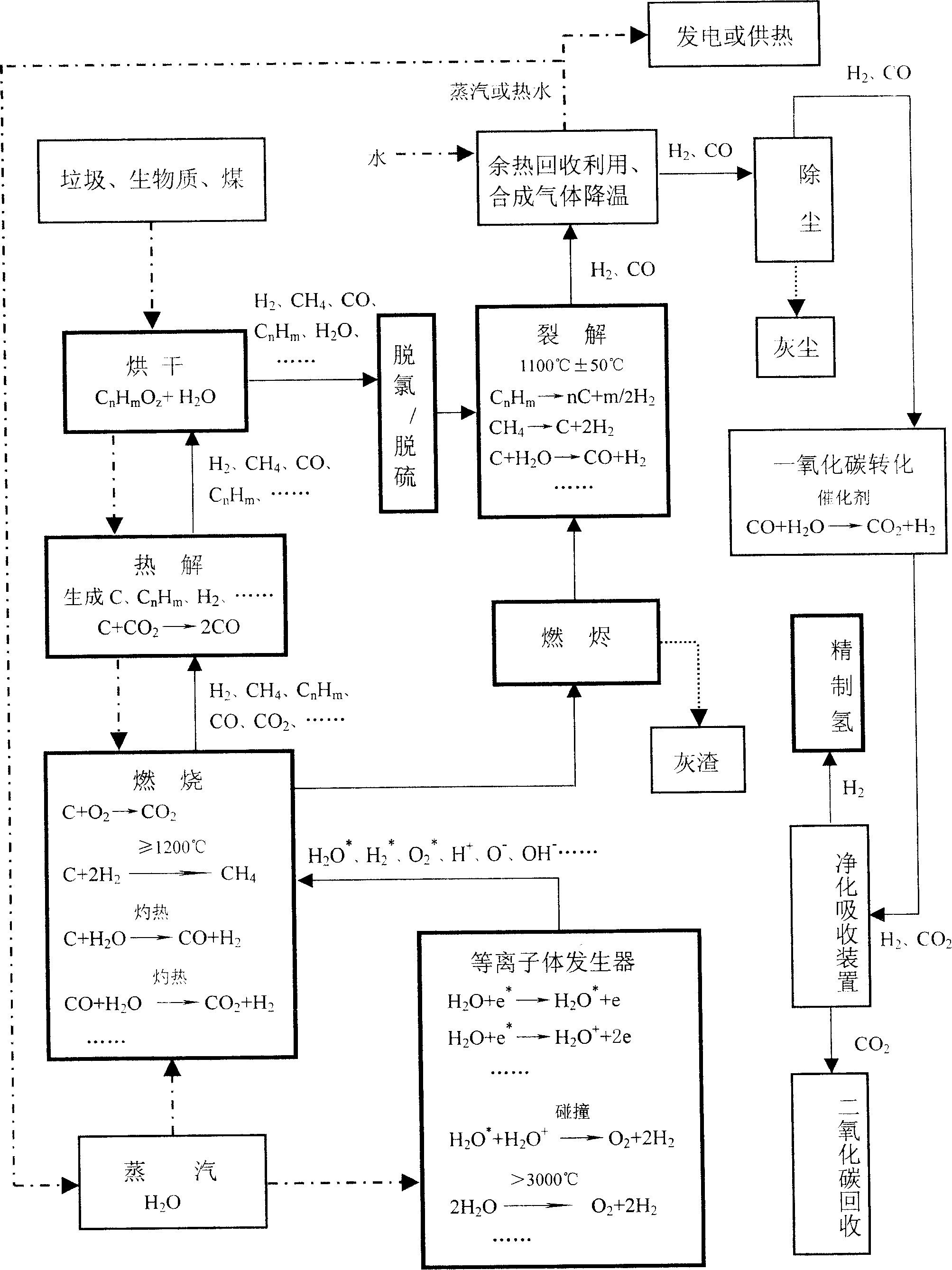

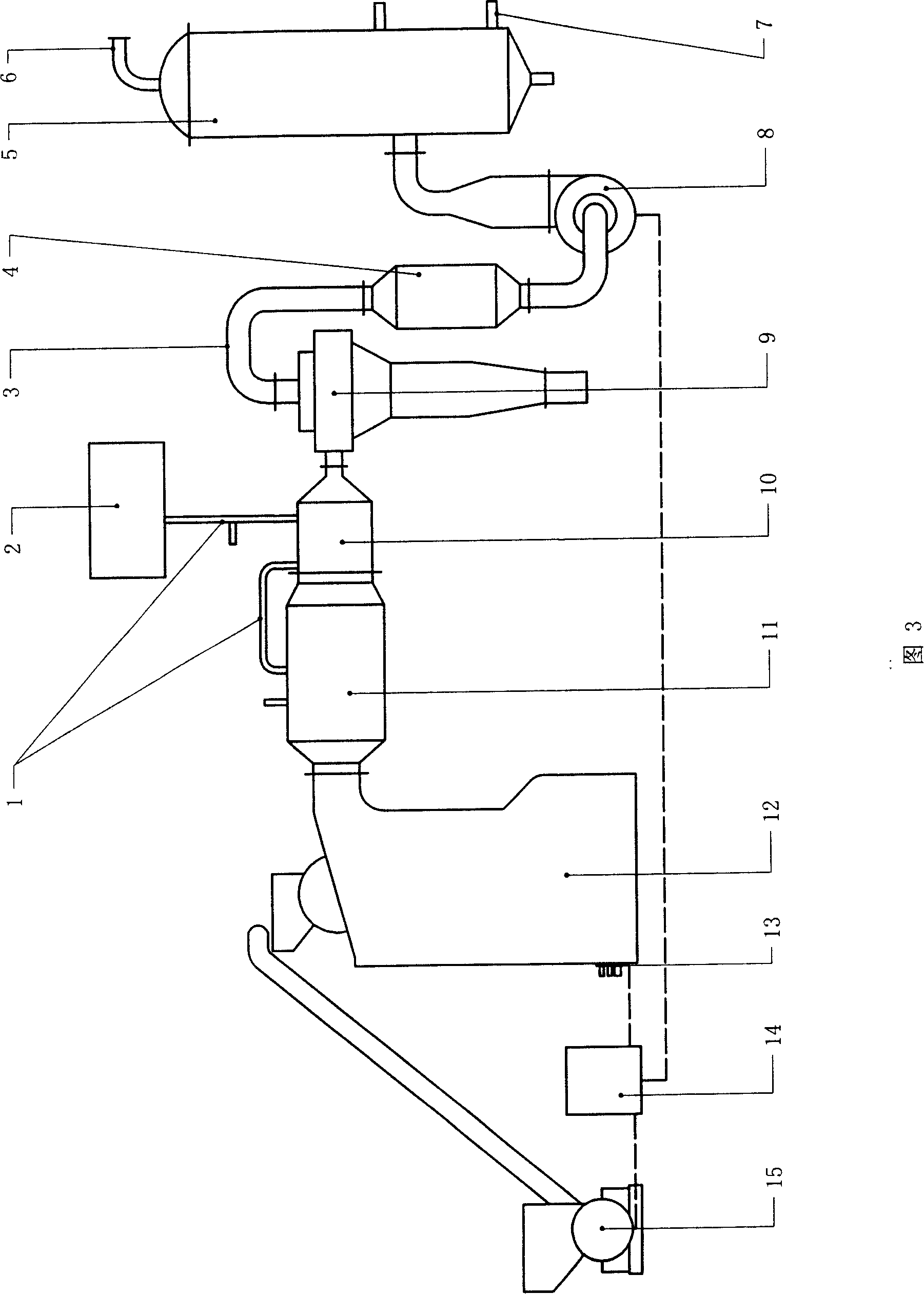

[0058] The hydrogen-rich synthesis gas produced by the plasma hydrogen production method and equipment using garbage, biomass and water as raw materials of the present invention has three post-treatment process flows: A. Passing through the secondary air for direct combustion, making it a Thermal energy equipment, I will apply for a patent in another case, so I will not describe it here; B. figure 1 As shown in the block diagram, after the high-temperature hydrogen-rich synthesis gas is recovered and cooled by waste heat and the dust is removed by the dust collector, the hydrogen-rich synthesis gas is stored in the gas cabinet through compression and cooling processes, and then supplied to gas users through pipelines or steel cylinders as gas use; C. such as figure 2 As shown, after the high-temperature hydrogen-rich synthesis gas is recovered and cooled by waste heat and dedusted by the dust collector, it passes through the carbon monoxide conversion device and reacts with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com