Application of ionic liquid in synthesis of propylene glycol ether and propylene glycol ether synthesis method

A technology of ionic liquid and propylene glycol ether, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalyst, ether preparation, etc., can solve the problems of difficult recycling and corrosion equipment, and achieve good basic catalysis Effect, low production cost, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention also provides a kind of propylene glycol ether synthetic method, described method comprises the steps:

[0017] Feed propylene oxide and alcohol into a reactor to contact with a catalyst, heat to 50°C-200°C in a closed environment to obtain the propylene glycol ether, wherein the catalyst is an imidazole acetate ionic liquid and / or a quaternary ammonium Acetate-like ionic liquids.

[0018] Specifically, the molar ratio of the propylene oxide to alcohol is 1:1-1:10, the molar ratio of the catalyst to propylene oxide is 1:10-1:1000, and the reaction time is 30-300 min. The pressure is usually between 0.1 and 1 MPa. Preferably, the molar ratio of the propylene oxide to alcohol is 1:5-1:4, and the molar ratio of the catalyst to propylene oxide is 1:50-1:200. More preferably, the alcohol is C 1 ~C 8 any of the alcohols.

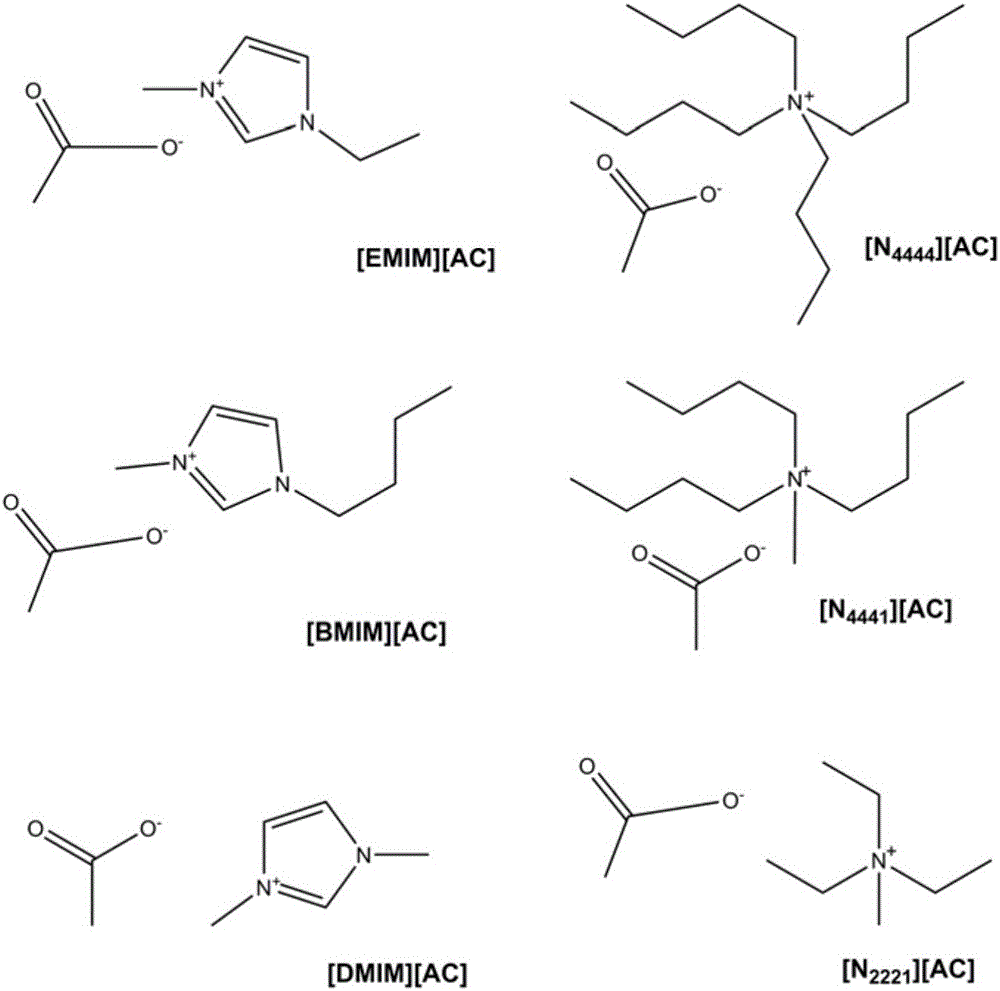

[0019] The imidazole acetate ionic liquid is at least one of [EMIM][AC], [DMIM][AC] and [BMIM][AC], and the quaternary ammonium ...

Embodiment 1

[0022] Synthesis of Ionic Liquid [N2221][AC]:

[0023] 1.91g of [N2221][MC], 1.2g of acetic acid was reacted in 3mL of water at room temperature for 1 hour and reacted. During the reaction, the methyl carbonate ionic liquid [N2221][MC] reacted with acetic acid to generate water and carbon dioxide, and finally generated [ N2221] [AC], the obtained solvent was washed three times with ether, and then dried in vacuum at 50° C. to obtain yellow crystals.

[0024] Propylene oxide, methanol and [N 2221 ][AC] mixed evenly and sent into the microwave reaction tube, in the microwave reactor, heated to 50 ℃, reacted for 30min. The composition of the obtained liquid phase mixture was measured by gas chromatography, and the conversion rate of propylene oxide was calculated to be 2.5%, and the selectivity of propylene glycol monomethyl ether was 89.6%.

Embodiment 2

[0026] Synthesis of Ionic Liquid [EMIM][AC]:

[0027] Potassium acetate (1.0 mol) was dissolved in 700 mL of anhydrous methanol at 70 °C, and 1-ethyl-3-methylimidazolium bromide [EMIM][Br] (1.0 mol) was dissolved in 100 mL of anhydrous methanol, Subsequently, the potassium acetate solution was added dropwise to the 1-ethyl-3-methylimidazolium bromide acetate solution within 5 minutes. During the dropwise addition process, KBr solids were constantly precipitated. After the dropwise addition was completed, the reaction was carried out for 2 hours. is 70°C. After cooling the complete solution, KBr was removed by filtration, and the filtrate was distilled under reduced pressure to remove anhydrous methanol, and finally obtained light yellow transparent sticky liquid 1-ethyl-3-methylimidazole acetate [EMIM][Ac ].

[0028] Mix propylene oxide, methanol and [EMIM][AC] with a molar ratio of 1:3:0.01 evenly and send them into a microwave reaction tube. In the microwave reactor, heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com