A kind of preparation method of the polyester fine denier yarn of 33dtex/144f

A technology of fine denier yarn and polyester, which is applied in the field of preparation of polyester fine denier yarn, can solve the problems that the intrinsic characteristics of ultra-fine denier fibers are difficult to reflect, the production difficulty is high, and the breakage rate is high, and the added value and competitiveness can be improved. The effect of poor mechanical properties and small fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

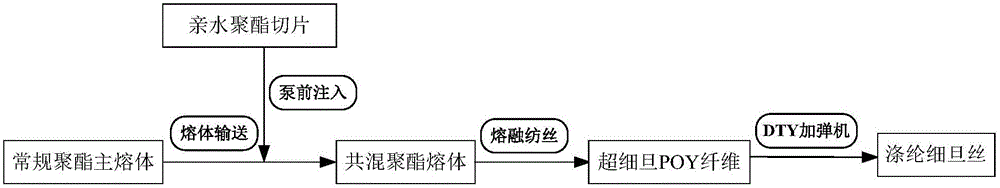

[0050] See attached figure 1 , Is the process flow chart of the present invention;

[0051] A method for preparing 33dtex / 144f polyester fine denier yarn, the specific steps are:

[0052] 1. Preparation of hydrophilic polyester chips

[0053] (1) Preparation of hydrophilic modifier:

[0054] Using nano-silica powder as raw material, under normal temperature conditions, high-speed stirring and ultrasonic dispersion in N,N-dimethylpyrrolidone solution, the dispersion time is 6-12h, and the high-speed stirring speed is 3000-4000 rpm In a nitrogen atmosphere, add toluene diisocyanate and react for 45-60 minutes at a reaction temperature of 135-155°C. After the reaction is complete, distill under reduced pressure for 45 minutes at 180°C, and then distill the product under reduced pressure. Drying at 120°C for 48h, the hydrophilic modifier is prepared.

[0055] The average particle size of nano-silica powder is 50-65 nanometers, the mass concentration of nano-silica in N,N-dimethylpyrrolid...

Embodiment 2

[0076] A method for preparing 33dtex / 144f polyester fine denier yarn, the specific steps are:

[0077] 1. Preparation of hydrophilic polyester chips

[0078] (1) Preparation of hydrophilic modifier:

[0079] Using nano-silica powder as raw material, under normal temperature conditions, high-speed stirring and ultrasonic dispersion in N,N-dimethylpyrrolidone solution, the dispersion time is 6-12h, and the high-speed stirring speed is 3000-4000 rpm In a nitrogen atmosphere, add toluene diisocyanate and react for 45-60 minutes at a reaction temperature of 135-155°C. After the reaction is complete, distill under reduced pressure for 45 minutes at 180°C, and then distill the product under reduced pressure. Drying at 120°C for 48h, the hydrophilic modifier is prepared.

[0080] The average particle size of nano-silica powder is 50-65 nanometers, the mass concentration of nano-silica in N,N-dimethylpyrrolidone is 30g / L, and the molar ratio of toluene diisocyanate to nano-silica is 1:8.

[0...

Embodiment 3

[0101] A method for preparing 33dtex / 144f polyester fine denier yarn, the specific steps are:

[0102] 1. Preparation of hydrophilic polyester chips

[0103] (1) Preparation of hydrophilic modifier:

[0104] Using nano-silica powder as raw material, under normal temperature conditions, high-speed stirring and ultrasonic dispersion in N,N-dimethylpyrrolidone solution, the dispersion time is 6-12h, and the high-speed stirring speed is 3000-4000 rpm In a nitrogen atmosphere, add toluene diisocyanate and react for 45-60 minutes at a reaction temperature of 135-155°C. After the reaction is complete, distill under reduced pressure for 45 minutes at 180°C, and then distill the product under reduced pressure. Dry for 48h at 120℃ to prepare hydrophilic modifier;

[0105] The average particle size of nano-silica powder is 50-65 nanometers, the mass concentration of nano-silica in N,N-dimethylpyrrolidone is 38g / L, and the molar ratio of toluene diisocyanate to nano-silica is 10.

[0106] The si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com